As a leading player in the construction industry, Geto Global Construction is dedicated to providing high-quality solutions tailored to our customers’ needs. In this article, we delve into the various types of aluminium formwork offered by Geto Global Construction, aiming to provide valuable insights for professionals and enthusiasts alike.

Understanding Aluminium Formwork

What are the different types of aluminium formwork? Aluminium formwork is a versatile and efficient construction system widely used in the industry today. Its lightweight yet durable nature makes it an ideal choice for various building projects. At Geto Global Construction, we offer a range of aluminium formwork solutions designed to streamline the construction process and enhance project efficiency.

Different Types of Aluminium Formwork

1. Traditional Aluminium Formwork: This type of formwork is the conventional choice for many construction projects. It offers durability, reusability, and ease of assembly, making it suitable for a wide range of applications.

2. Table Formwork: Table formwork systems are designed to support large slab areas during the concrete pouring process. They provide a stable working platform and can be easily adjusted to accommodate different project requirements.

3. Quick-Deck System: Our Quick-Deck system is engineered for rapid assembly and disassembly, allowing for efficient construction progress. It offers enhanced flexibility and productivity, making it an ideal choice for time-sensitive projects.

Advantages of Geto Aluminium Formwork

Optimized Efficiency: Our aluminium formwork systems are engineered to streamline the construction process, reducing labor costs and project timelines.

Superior Quality: We prioritize quality in every aspect of our products, ensuring durability, reliability, and consistency across all projects.

Customization Options: At Geto Global Construction, we understand that every project is unique. That’s why we offer customizable solutions to meet specific project requirements and preferences.

Additional Section: Sustainability and Environmental Benefits

In addition to their efficiency and performance advantages, Geto Global Construction’s aluminium formwork systems also contribute to sustainability and environmental responsibility in construction practices. Here are some key points to consider:

Reduced Material Waste: Aluminium formwork systems are designed for reusability, minimizing material waste compared to traditional formwork methods. This reduction in waste helps conserve resources and lowers the environmental impact of construction projects.

Energy Efficiency: Aluminium is a highly recyclable material, requiring less energy for recycling compared to producing new aluminium. By using aluminium formwork systems, construction projects can contribute to energy conservation and reduce carbon emissions associated with material production.

Conclusion

In conclusion, Geto Global Construction offers a comprehensive range of aluminium formwork solutions designed to optimize efficiency and performance in construction projects. With our commitment to quality, innovation, and customer satisfaction, we strive to be the preferred choice for professionals worldwide.

Whether you’re embarking on a new construction project or looking to upgrade your existing formwork system, trust Geto Global Construction for reliable, high-quality solutions that deliver results.

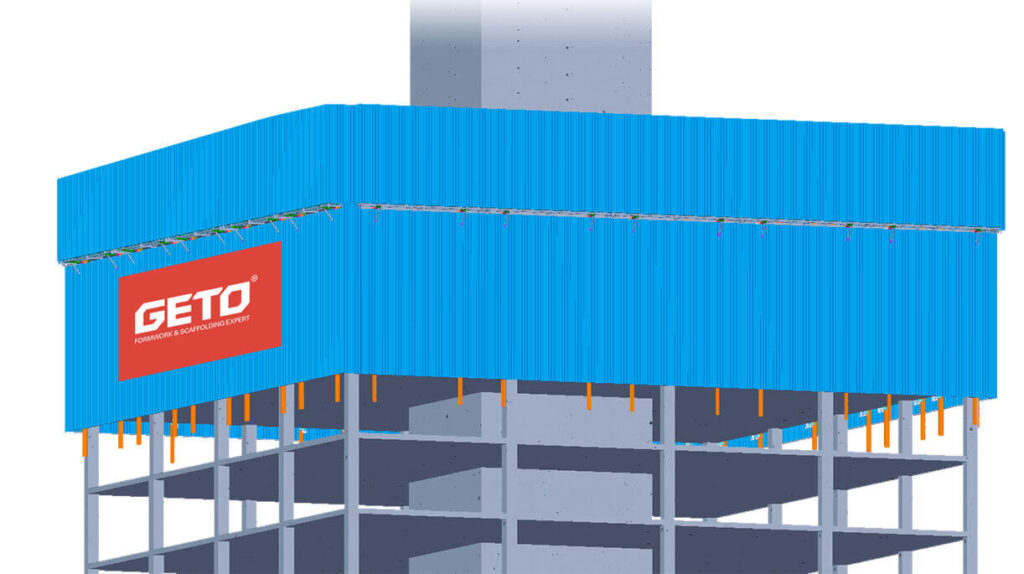

At Geto Global Construction, we pride ourselves on offering innovative solutions tailored to meet the evolving needs of the construction industry. Among our cutting-edge products is the self-climbing platform, a revolutionary tool designed to streamline construction processes and enhance efficiency. But whatisself-climbing platform, and how does it benefit construction projects? Let’s delve into this transformative technology.

Understanding Self-Climbing Platforms

Self-climbing platforms are advanced systems used in high-rise construction projects to facilitate vertical movement of workers and materials. Unlike traditional scaffolding, which requires manual dismantling and reassembly as construction progresses, self-climbing platforms feature automated mechanisms that enable them to ascend along the building’s exterior, keeping pace with the construction process. This automation significantly reduces downtime and enhances productivity on the job site.

How Self-Climbing Platforms Work

Utilizing a combination of hydraulic systems, motors, and sophisticated controls, self-climbing platforms operate in a cyclic fashion, gradually moving upwards as construction proceeds. Workers can easily access different levels of the building without the need for extensive manual labor, thereby optimizing workflow and minimizing disruptions. Additionally, these platforms are equipped with safety features to ensure the well-being of personnel working at height, further enhancing overall job site safety.

Advantages of Self-Climbing Platforms

1. Enhanced Productivity: By eliminating the need for manual dismantling and reassembly, self-climbing platforms streamline construction processes, allowing for faster completion of projects.

2. Improved Safety: With built-in safety features and automated controls, self-climbing platforms mitigate risks associated with working at height, reducing the likelihood of accidents and injuries.

Advancing Construction Practices with Self-Climbing Platforms

In addition to their immediate benefits, self-climbing platforms also contribute to the advancement of construction practices as a whole. By optimizing workflow and minimizing the reliance on manual labor, these platforms enable construction companies to tackle projects of greater complexity and scale with ease. Moreover, the automation inherent in self-climbing platforms fosters a culture of innovation within the industry, encouraging further developments in construction technology.

Conclusion: Elevating Construction Efficiency with Self-Climbing Platforms

In conclusion, self-climbing platforms represent a significant advancement in construction technology, offering unparalleled efficiency, safety, and cost-effectiveness. At Geto Global Construction, we are committed to harnessing the power of innovation to empower construction professionals and elevate industry standards. Contact us today to learn more about how self-climbing platforms can optimize your next project.

As we embark on construction projects, the choice of formwork plays a pivotal role in determining the success and efficiency of our endeavors. At Geto Global Construction, we prioritize innovation and excellence in providing solutions for modern construction needs. Among our array of offerings, aluminium formwork stands out as a reliable and efficient choice. Let’s delve into why opting for aluminium formwork from Geto Global Construction is a prudent decision for your construction projects.

The Advantages of Aluminium Formwork

Why use aluminium formwork? Aluminium formwork offers a multitude of benefits that contribute to streamlined construction processes and superior outcomes.

1. Enhanced Efficiency

Aluminium formwork is renowned for its lightweight yet robust nature, facilitating swift assembly and disassembly processes. With its precise engineering and seamless interlocking systems, our aluminium formwork solutions ensure efficient construction workflows, saving both time and labor costs.

2. Superior Quality

Quality is paramount in construction, and our aluminium formwork systems are engineered to deliver impeccable results. The precision and durability of aluminium formwork ensure consistent concrete pouring, resulting in high-quality structures with minimal defects. By eliminating the need for traditional timber formwork, our solutions elevate the overall quality of construction projects.

3. Eco-Friendly Approach

Sustainability is at the core of our values, and aluminium formwork aligns with our commitment to eco-friendly practices. Unlike traditional formwork materials, aluminium is recyclable and reusable, reducing waste and minimizing environmental impact. By choosing aluminium formwork from Geto Global Construction, you contribute to a greener future for the construction industry.

Seamless Integration with Geto’s Comprehensive Solutions

At Geto Global Construction, we offer more than just products – we provide comprehensive solutions tailored to meet your specific needs. Our expertise extends beyond aluminium formwork, encompassing scaffolding systems, PC components, and a myriad of construction materials. By integrating our aluminium formwork solutions with our suite of offerings, you unlock synergies that optimize your construction processes and elevate project outcomes.

Conclusion: Elevate Your Construction Projects with Geto’s Aluminium Formwork

In conclusion, the decision to utilize aluminium formwork from Geto Global Construction is a strategic investment in efficiency, quality, and sustainability. With its array of benefits, including enhanced efficiency, superior quality, and eco-friendly attributes, aluminium formwork stands as the preferred choice for modern construction projects. By partnering with Geto Global Construction, you gain access to innovative solutions and unparalleled expertise that propel your projects to success. Choose aluminium formwork with Geto Global Construction and experience the difference in your construction endeavors.

What are the benefits of aluminum formwork? At Geto Global Construction, we understand the importance of utilizing advanced construction materials to optimize building processes and enhance project outcomes. One such material that stands out for its numerous benefits is aluminum formwork. In this article, we’ll delve into the advantages of aluminum formwork and why it’s a preferred choice in the construction industry.

1. Lightweight and Durable Construction Solution

Aluminum formwork offers a lightweight yet durable solution for constructing various structures, including residential and commercial buildings. Unlike traditional materials such as wood or steel, aluminum formwork provides the perfect balance of strength and portability. Its lightweight nature facilitates easy handling and installation on-site, leading to improved construction efficiency.

2. Enhanced Efficiency and Cost-effectiveness

One of the key advantages of aluminum formwork is its ability to streamline the construction process, thereby reducing overall project timelines and costs. With its reusable and recyclable properties, aluminum formwork enables multiple cycles of use, resulting in significant cost savings over time. Additionally, its precision-engineered components ensure consistent quality and accuracy in every pour, minimizing material wastage and rework.

3. Superior Quality and Structural Integrity

Aluminum formwork delivers superior quality and structural integrity, ensuring robust and resilient construction outcomes. Its rigid framework and precise dimensions allow for seamless assembly and alignment, leading to smooth and uniform concrete finishes. Moreover, aluminum’s corrosion-resistant properties make it an ideal choice for long-term durability, even in challenging environmental conditions.

Furthermore, the versatility of aluminum formwork extends beyond its primary benefits, offering adaptability to various architectural designs and project requirements. Its modular nature allows for customization, enabling builders to create intricate shapes and configurations with ease. Whether constructing residential complexes, commercial towers, or infrastructure projects, aluminum formwork provides the flexibility to meet diverse construction needs while maintaining consistency and efficiency throughout the building process.

Conclusion: Elevating Construction Standards with Aluminum Formwork

In conclusion, aluminum formwork stands as a testament to innovation and efficiency in modern construction practices. With its lightweight design, cost-effective benefits, and superior quality, aluminum formwork offers a compelling solution for builders and developers alike. At Geto Global Construction, we are proud to champion the use of aluminum formwork to optimize construction processes, enhance project outcomes, and deliver exceptional value to our clients.

By incorporating aluminum formwork into your construction projects, you can unlock a myriad of benefits that elevate standards and drive success in the ever-evolving construction industry.

Remember, when it comes to construction materials, choose aluminum formwork for unparalleled efficiency, durability, and quality. Experience the difference with Geto Global Construction today.

What is the difference between plywood formwork and aluminium formwork? At Geto Global Construction, we understand the importance of choosing the right formwork for your construction projects. With our expertise in the industry, we aim to provide valuable insights into the differences between plywood formwork and aluminium formwork, helping you make informed decisions for your construction needs.

Understanding Plywood Formwork

Plywood formwork has been a traditional choice for construction projects due to its affordability and availability. This type of formwork is typically made from layers of wood veneer glued together, offering a sturdy structure for concrete pouring. While plywood formwork has been widely used, it comes with its own set of limitations.

1. Material Durability: Plywood formwork, being made from wood, is susceptible to water damage and deterioration over time, especially in humid or wet conditions. This can lead to warping, swelling, and reduced lifespan of the formwork.

2. Limited Reusability: Although plywood formwork can be reused for multiple construction cycles, its lifespan is shorter compared to aluminium formwork. The frequent need for replacement adds to the overall project costs and logistical challenges.

Advantages of Aluminium Formwork

Aluminium formwork, on the other hand, presents a modern and efficient solution for construction projects, offering several distinct advantages over plywood formwork.

1. Enhanced Durability: Aluminium formwork is highly resistant to corrosion and weathering, making it suitable for various environmental conditions. Its durable nature ensures long-term performance and minimizes the need for frequent replacements.

2. Optimized Efficiency: With precise design and lightweight construction, aluminium formwork allows for faster assembly and disassembly, resulting in improved construction timelines and reduced labor costs. The system’s modular components enable seamless integration and customization for diverse project requirements.

3. Cost-Effectiveness: While aluminium formwork may have a higher initial investment compared to plywood formwork, its long-term benefits outweigh the upfront costs. The enhanced durability and reusability of aluminium formwork translate into significant savings over the project’s lifecycle.

Conclusion: Making Informed Choices

In conclusion, the choice between plywood formwork and aluminium formwork depends on various factors such as project budget, timeline, and environmental conditions. While plywood formwork offers affordability, aluminium formwork provides superior durability, efficiency, and cost-effectiveness in the long run. At Geto Global Construction, we offer innovative solutions tailored to meet your construction needs, ensuring optimal performance and value for your projects.

With our expertise and comprehensive product range, we empower construction professionals to achieve excellence in their projects while maximizing efficiency and minimizing costs. Choose Geto Global Construction for reliable solutions and unparalleled support in your construction endeavors.

At Geto Global Construction, we are committed to offering top-notch construction solutions, with a focus on aluminum formwork systems. As an industry leader, we understand the importance of using high-grade materials in our products to ensure durability, efficiency, and cost-effectiveness. In this article, we delve into the grade of aluminum used for formwork and why it matters in construction projects.

Understanding Aluminum Grades for Formwork

What grade of aluminum is used for formwork? Aluminum formwork systems are renowned for their versatility, durability, and ease of use in construction projects. However, not all aluminum is created equal. The grade of aluminum used plays a crucial role in determining the performance and longevity of formwork systems.

The Importance of High-Quality Aluminum

At GETO Global Construction, we exclusively utilize high-grade aluminum alloys in our formwork systems. These alloys are specifically chosen for their exceptional strength, corrosion resistance, and longevity. By using premium-grade aluminum, we ensure that our formwork systems can withstand the rigors of construction, including heavy loads, harsh weather conditions, and repetitive use.

Advantages of Premium Aluminum Formwork

1. Enhanced Durability: High-grade aluminum alloys offer superior durability, ensuring that our formwork systems maintain their structural integrity even after multiple uses.

2. Improved Efficiency: With premium aluminum formwork, construction projects can be completed more efficiently, thanks to faster assembly and disassembly times.

3. Cost-Effectiveness: While premium-grade aluminum may come at a slightly higher initial cost, it proves to be a cost-effective investment in the long run due to its extended lifespan and minimal maintenance requirements.

The GETO Difference

At GETO Global Construction, quality is our top priority. We go above and beyond to source the finest materials and employ stringent quality control measures to ensure that our products meet the highest standards. When it comes to aluminum formwork, we spare no effort in selecting the most suitable grade of aluminum to deliver exceptional performance and value to our customers.

Conclusion

In conclusion, the grade of aluminum used for formwork is a critical factor that directly impacts the quality and longevity of construction projects. By choosing premium-grade aluminum alloys, such as those used by GETO Global Construction, builders can enjoy enhanced durability, efficiency, and cost-effectiveness in their projects. Experience the difference of superior quality formwork systems with GETO Global Construction today.

With a commitment to excellence and a focus on quality, GETO Global Construction sets the standard for premium construction solutions. Contact us to learn more about our aluminum formwork systems and how they can elevate your next project.

What is aluminium formwork in construction? At Geto Global Construction, we understand the importance of innovation and efficiency in the construction industry. That’s why we’re excited to explore the benefits of aluminium formwork and how it’s revolutionizing construction processes worldwide.

Understanding Aluminium Formwork

Aluminium formwork is a versatile construction system that replaces traditional methods such as timber or steel formwork. It involves the use of prefabricated aluminium panels that are assembled on-site to create the desired structure for concrete pouring. This system offers numerous advantages over conventional formwork, making it a preferred choice for modern construction projects.

The Advantages of Aluminium Formwork

1. Enhanced Efficiency: Aluminium formwork significantly speeds up the construction process compared to traditional methods. Its lightweight and modular design allow for quick assembly and dismantling, resulting in shorter construction cycles and increased productivity.

2. Improved Quality: With precise fabrication and assembly, aluminium formwork ensures high-quality concrete finishes with minimal defects. The uniformity and consistency achieved with this system contribute to superior structural integrity and aesthetics of the final building.

3. Cost-Effectiveness: While the initial investment in aluminium formwork may be higher than traditional methods, the long-term cost savings are substantial. The reusable nature of aluminium formwork reduces material waste and labor expenses, ultimately leading to lower overall project costs.

How Geto Global Construction Leads the Way

At Geto Global Construction, we specialize in providing cutting-edge aluminium formwork solutions tailored to our clients’ needs. With our expertise and industry-leading technology, we optimize the construction process to deliver exceptional results efficiently and cost-effectively.

Elevating Construction Standards with Aluminium Formwork

The adoption of aluminium formwork not only streamlines construction processes but also raises the bar for construction standards. By promoting consistency, precision, and sustainability, aluminium formwork sets a new benchmark for efficiency and quality in the construction industry. As a pioneer in this field, Geto Global Construction is committed to driving innovation and excellence in construction practices worldwide.

Conclusion: Building the Future with Aluminium Formwork

In conclusion, aluminium formwork represents a game-changing innovation in the construction industry, offering unparalleled efficiency, quality, and cost-effectiveness. As a leading provider of construction solutions, Geto Global Construction is proud to be at the forefront of this revolution, empowering our clients to build the future with confidence and success. With our commitment to excellence and sustainability, we continue to shape the landscape of construction for generations to come.

As a leading player in the construction materials industry, Geto Global Construction takes pride in offering innovative solutions that enhance efficiency and quality in construction projects. Our aluminum formwork system has been a cornerstone in revolutionizing construction practices, but it’s essential to acknowledge potential drawbacks to make informed decisions. In this article, we delve into the disadvantages of aluminum formwork, providing valuable insights for construction professionals and developers.

Understanding Aluminium Formwork

Before exploring its drawbacks, let’s briefly understand what aluminum formwork entails. Our aluminum formwork system is renowned for its lightweight, durable, and reusable properties, making it a preferred choice for various construction projects worldwide. Its efficiency in speeding up construction timelines and maintaining structural integrity has been well-documented.

The Disadvantages of Aluminium Formwork

What is the disadvantage of aluminium formwork? While aluminum formwork offers numerous advantages, it’s essential to consider potential drawbacks:

1. Initial Cost Implications: One notable drawback is the initial investment required for aluminum formwork. Compared to traditional formwork materials like timber or steel, aluminum formwork systems may have a higher upfront cost. However, it’s crucial to view this as a long-term investment, considering its durability and reusability benefits.

2. Limited Flexibility: Another drawback is the limited flexibility in design compared to traditional formwork methods. Aluminum formwork systems are typically prefabricated and may not accommodate complex architectural designs or irregular shapes as effectively. While suitable for standard floor layouts, customization options may be limited.

3. Specialized Training Requirements: Utilizing aluminum formwork systems effectively requires specialized training for construction teams. Unlike traditional formwork methods, which may be more familiar to workers, operating aluminum formwork systems demands proficiency in assembly, disassembly, and maintenance. Additional training costs and time investments may be necessary to ensure optimal usage.

Overcoming Challenges with Strategic Solutions

While acknowledging these disadvantages, it’s crucial to emphasize that they can be effectively mitigated with strategic solutions:

Cost-Benefit Analysis: Conducting a thorough cost-benefit analysis can help stakeholders understand the long-term advantages of aluminum formwork systems. By considering factors such as project timelines, labor costs, and material savings, the initial investment can be justified.

Collaborative Design Approaches: Collaboration between architects, engineers, and construction teams can help optimize design solutions compatible with aluminum formwork systems. By leveraging digital tools and innovative design techniques, complex architectural requirements can be accommodated effectively.

Comprehensive Training Programs: Investing in comprehensive training programs ensures that construction teams are equipped with the necessary skills to maximize the benefits of aluminum formwork systems. Hands-on training, coupled with ongoing support and guidance, enhances operational efficiency and safety on-site.

Conclusion

In conclusion, while aluminum formwork systems offer significant advantages in construction projects, it’s essential to acknowledge and address potential drawbacks proactively. By understanding the challenges associated with aluminum formwork and implementing strategic solutions, construction professionals can harness its full potential to optimize project outcomes. At Geto Global Construction, we remain committed to providing innovative solutions and comprehensive support to meet the evolving needs of the construction industry.

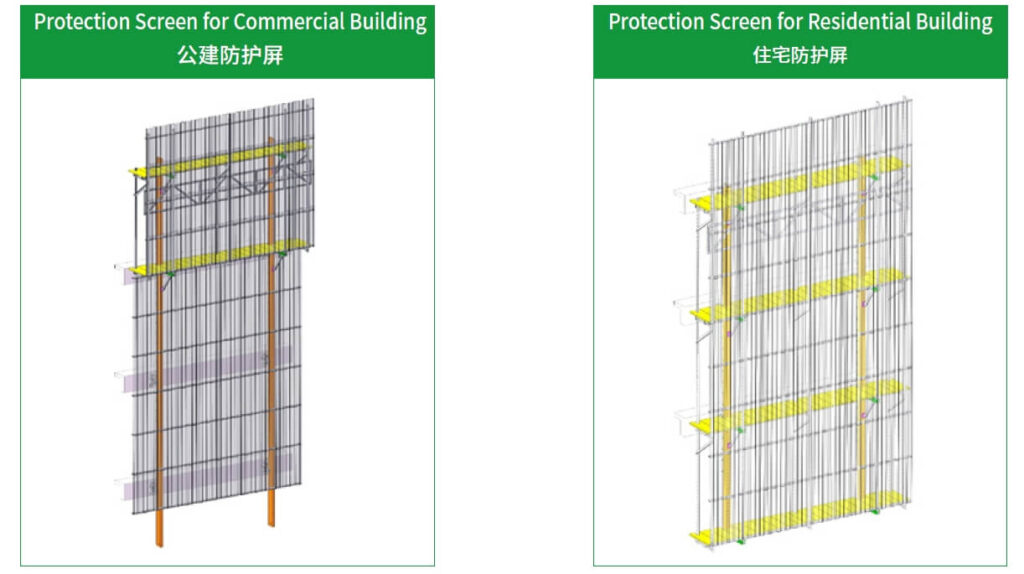

Protection screen is an innovative safety device attached to structures (floors, beams, or walls) and lifted using a tower crane or hydraulic system. Specifically designed to fulfill peripheral protection needs for high-rise and super-high-rise buildings.

There are obvious differences between the facade walls of commercial and residential buildings. Residential buildings typically have many facades, demanding protection screens for exterior work, while commercial buildings’ fewer facades permit work from internal edges.

Therefore, GETO protection screens are categorized into residential protection screens with more platform layers, and commercial building protection screens with fewer platform layers.

① Guide rails and platform boards are 0.3m from the wall for easy installation of beam and wall formwork.

② Seal flaps can be installed as needed.

High wind resistance

▪ Capable of withstanding a maximum wind load of 9 levels without extra reinforcement. Additional reinforcement is needed for wind loads beyond level 9.

Fall arrest

▪ Fall arrest devices attached during climbing are independent, minimizing safety issues resulting from operational errors.

▪ Protection against personnel and items being dropped is ensured by full sealing, including guide rails, corners, and protruding parts.

▪ All components undergo rigorous testing, including extreme loads and falls, to ensure safety in extreme conditions.

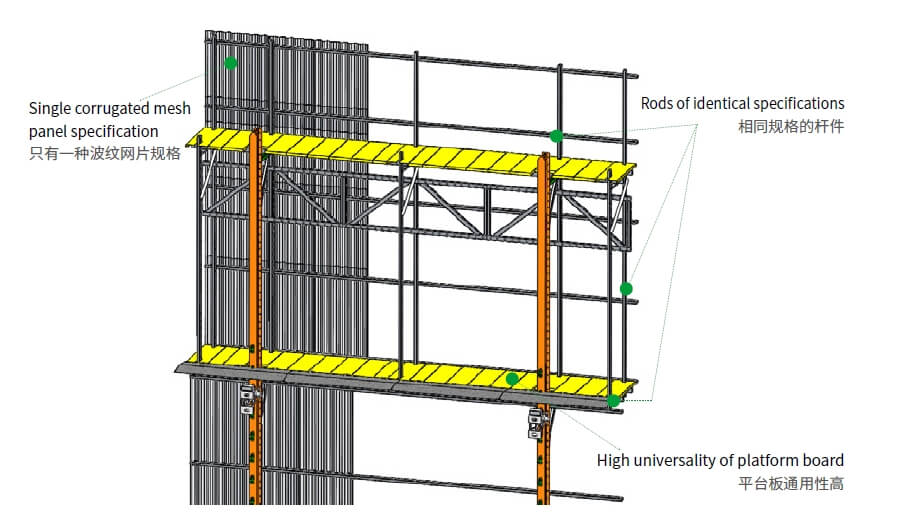

▪ Strong universality of components for easy management.

Main components do not exceed 10 types, achieving a universal compatibility rate of 95% or higher.

▪ Hydraulic drive system.

Compared to conventional protection platform using electric hoists and electronically controlled, the cost is lower.

▪ Reliable, maintainable, and easy to operate.

▪ Lower costs for disassembly, transportation, and labor due to the lightweight frame compared to regular steel climbing platforms.

▪ Suitable for diverse shapes and heights of structure. Adjustable floor supports permit use on facades with both varying and constant inclinations.

▪ Platform boards and sealed flaps can align with floor levels.

| S/N | Item | Unit | Specification | Remark |

| 1 | Framework height | m | 8~13.5 | Adapting framework height to project conditions |

| 2 | Framework width | m | 0.6-1.2 | Standard platform board width: 0.88m |

| 3 | Machine position affecting width | m | 3.5 | Total length varies with machine position count |

| 4 | Single unit weight | T | 1.3 | Calculating based on a 2.5-level protection screen, with a machine position affecting width of 3.5m |

| 5 | Rated lifting capacity of the power unit | T | 3.5 | Hydraulic cylinders, pump station |

| 6 | Power unit capacity | KW | 1.5 | Voltage: 380V/415V, Frequency: 50Hz, Max fuse current: 5A (Motor can be customized based on local electrical specifications) |

| 7 | Single lift height of hydraulic cylinder | m | 0.3 | Effective lift height: 0.3mTotal cylinder stroke: 0.42m |

| 8 | Lifting speed | m/min | 0.3 | |

| 9 | Time for lifting one level | min | 10 | Calculating based on a 3m floor height |

| 10 | Platform load capacity | kN/㎡ | 2 | Operating on a two-level platform (200kg/m² load capacity per level) |

Scaffolding is the backbone of any construction project, providing the crucial support needed to elevate structures to new heights. At GETO Global Construction, we take pride in offering a diverse range of scaffolding solutions that cater to the unique demands of various construction scenarios. In this article, we talk about of types of scaffolding used in construction, exploring traditional techniques, cutting-edge innovations, and specialized solutions that collectively contribute to redefining construction excellence.

Traditional Scaffolding Techniques: A Time-Tested Approach

Traditional scaffolding has been a stalwart in the construction industry, built on time-tested principles that prioritize stability and safety. Our scaffolding systems adhere to these core principles, providing a reliable framework that withstands the challenges posed by different construction environments.

Whether it’s a sprawling high-rise or a compact renovation project, traditional scaffolding remains adaptable, proving its mettle across diverse construction environments. At GETO Global Construction, we recognize the importance of this approach, offering scaffolding solutions that cater to the specific needs of each project.

Construction scaffolding, set up at specific heights and attached to the engineering structure, forms the crux of our traditional scaffolding approach. Relying on advanced lifting equipment and devices, our scaffolding systems can ascend or descend layer by layer with the engineering structure. Anti-overturning and anti-falling devices are integrated, effectively enhancing safety during construction activities.

Cutting-Edge Innovations: Modern Scaffolding Systems

In the contemporary construction landscape, innovation is paramount. GETO Global Construction does well in cutting-edge safety features and efficiency enhancements embedded in our modern scaffolding systems. From advanced guardrails to enhanced stability measures, our innovations prioritize the well-being of workers, contributing to a secure and efficient working environment.

We don’t just follow industry trends; we set them. Our commitment to pioneering change is evident in the continuous evolution of our scaffolding systems. By integrating state-of-the-art technologies, we ensure that our scaffolding not only meets but exceeds the expectations of modern construction projects.

Specialized Solutions: Tailoring Scaffolding to Unique Construction Needs

Construction projects are as unique as fingerprints, and so should be the scaffolding solutions. GETO Global Construction specializes in tailoring scaffolding to the specific requirements of each project. Whether it’s a complex architectural design or a project with challenging terrain, our customized solutions ensure that scaffolding adapts seamlessly to project needs.

Real-world success stories demonstrate the transformative impact of our specialized scaffolding solutions. Through case studies, we highlight projects of varying scales and complexities where our tailored scaffolding approaches have contributed to elevated safety standards and enhanced construction efficiency.

Conclusion: Shaping Construction Excellence with Diverse Scaffolding Solutions from GETO Global Construction

In conclusion, the diverse types of scaffolding available play a pivotal role in shaping construction excellence. At GETO Global Construction, we pride ourselves on offering a spectrum of scaffolding solutions that not only support construction projects but redefine the possibilities within the industry. Choose GETO Global Construction for scaffolding that adapts, innovates, and elevates your construction endeavors to unprecedented heights.