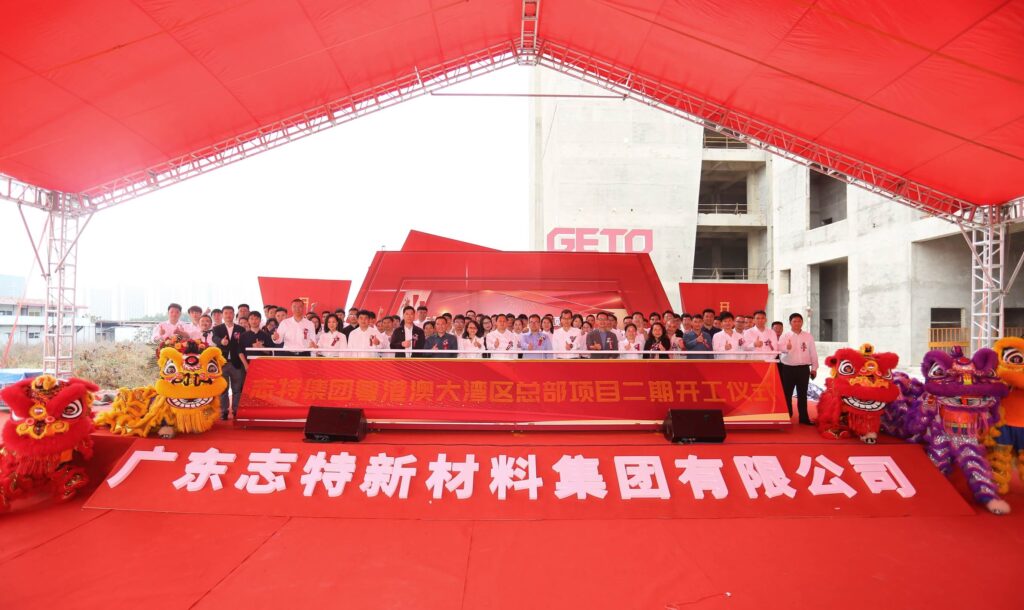

On the morning of March 23, GETO Group grandly held a groundbreaking ceremony for its Guangdong-Hong Kong-Macao Greater Bay Area Headquarters Project Phase II. GETO New Material is mainly engaged in green new-type building aluminium formwork system, self-climbing platform, and assembly PC components. Our business segments cover the fields of civil and public construction. At present, we have established more than 10 production bases around the world, and our products sell well in more than 30 countries and regions.

Published: Mar 30, 2023

Last published: Mar 17, 2023

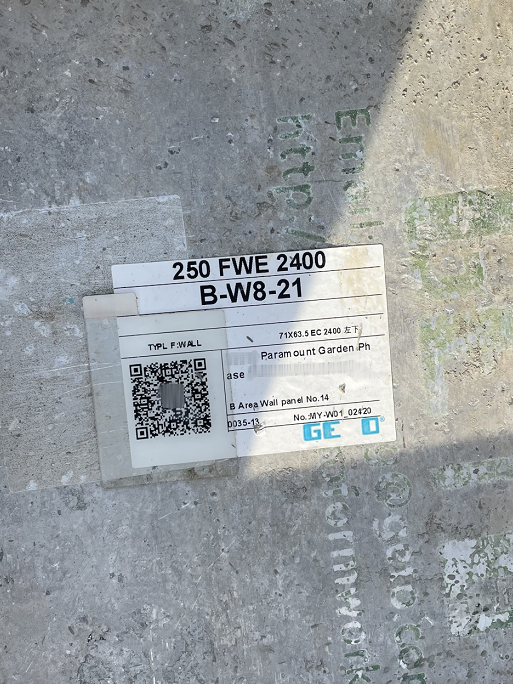

GETO continuously upgrades our built-in Information Technology System that covers both ERP system and CRM system. Backed up by advanced information technology in place, GETO has realized modernized, integrated, and standardized information flow management. Meanwhile, GETO can offer custom-made information system services, including an ERP warehousing system for our clients upon payment done.

GETO will put the QR code sticker with the information such as the tower details and the location of the materials that shall be used. Like 250 FEW 2400 is the panel specification or B-w8-21 is represented the location of the panel. A scanner device shall be used during the material is ready to pack and GETO will scan all the stickers on the material to make sure there is no material missing before packing and avoid insufficient material on site.

GETO has provided the aluminium formwork system leasing service to a customer where One City Residence in Penang, Malaysia. GETO assigned the supervisor to use the scanner while returning the aluminium formwork at the construction site to ensure that the material is returned and it can help to identify which materials were lost. It also helps customer to save time on returning the aluminium formwork system while the leasing period is ended. Compared to some other traditional suppliers in the market who would do the record by handwriting, GETO is more efficient and time-saving.

Published: Mar 17, 2023

Last published: Feb 28, 2023

To further expand the scope of support for clean winter heating in Northern China and continuously promote green development, some Chinese national departments and administration jointly issued the Notice on Organizing the Application of Clean Winter Heating Projects in Northern China recently. We started to apply for subsidies for clean heating in cities in northern China except those that were included in the central government’s pilot program for winter clean heating from 2017 to 2019.

There are two application forms of the combination of solar energy and building energy saving, one is BIPV (Building-Integrated Photovoltaics) and another is BIST (Building-Integrated Solar Thermal).

According to a chairman of a Chinese technology company, BIST is the roofing system or metope system made up of light and heat components. By absorbing solar radiant heat, it is used for domestic hot water supply and winter building heating. It can also become an important direction of existing building transformation in our country.

Currently, GETO not only sells aluminium form, self climbing platform and scaffolding platform, but has photovoltaic support products on sale as well. It will be connected simply with the building, which promotes the large-scale application of “solar energy+buildings” to promote rural revitalization and the construction of beautiful villages.

From the development trend of the whole industry, both internal and external factors are very supportive of the deep combination of the construction field and the utilization of solar energy. In the near future, Building-Integrated Photovoltaics and Building-Integrated Solar Thermal is the vital way.

Published: Mar 17, 2023

Last published: Feb 28, 2023

For a long time, China’s construction industry has huge production capacity, but the internationalization rate of construction enterprises is low. In the context of the globalization of the world economy and the integration of international production, enterprises can only reduce costs and increase efficiency by deploying their production resources in the world through international operations. Many internationally renowned engineering giants have been able to survive and develop in the competitive market for a long time as they have their core competitiveness. Meanwhile, the practice of most successful international engineering contractors shows that their core competitiveness mainly comes from their ability in business integration and multinational operation based on years of experience in international projects.

From the perspective of the domestic construction industry, China has entered the middle and late stages of faster development of urbanization. The number of new projects such as housing construction is shrinking, industry structure and business model are facing transformation and upgrading, and the development model is constantly shifting to high-quality development. For the majority of construction enterprises, the international market is inevitable in promoting the development and growth of enterprises.

From the “Belt and Road” initiative to the end of July 2022, 149 countries and 32 international organizations around the world have signed more than 200 cooperation documents with China on the “Belt and Road”, and contracted more than 3,000 projects with an investment scale of nearly $1 trillion. These projects ranged from dams and bridges to ports and railroads, which brought about the upgrading of infrastructure in countries along the route and new development opportunities for Chinese construction companies and construction materials suppliers.

GETO, as one of China’s aluminum formwork suppliers, keenly realized the importance of internationalization, so it vigorously developed the overseas market and set up subsidiaries in Singapore and Malaysia. To seize the business opportunities in overseas markets as soon as possible, GETO seized the opportunity of the wave of infrastructure construction in the “Belt and Road” countries to provide aluminum formwork for the construction of infrastructure.

Published: Feb 28, 2023

Last published: Feb 17, 2023

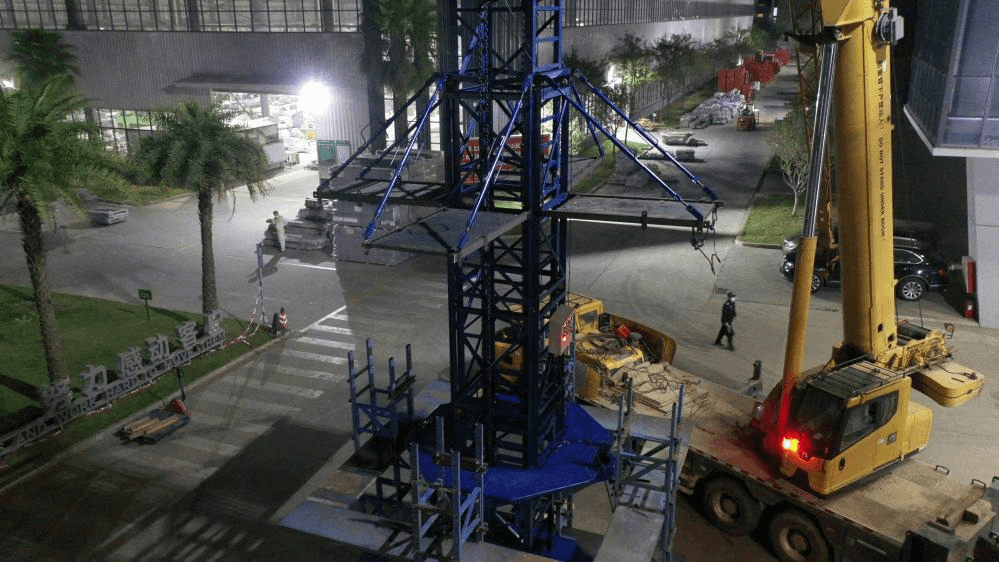

GETO Hydraulic self-climbing formwork is the optimal solution for the cores of super high-rise buildings (over 150 meters), including both concrete core walls and frame structure cores, as well as for shear walls.

It is made up of formwork panels, a climbing mechanism, a working platform, hydraulic jacks, and a power unit. The formwork panels are used to create the shape of the concrete structure, and the climbing mechanism, which is powered by hydraulic jacks and a power unit, allows the formwork to be raised or lowered vertically as the structure is being built. The formwork panels are typically made from materials such as wood, steel, or aluminum. The hydraulic system is powered by a motor and uses hydraulic cylinders to move the formwork up and down the structure.

As the formwork system climbs up the building, the workers install new formwork on the next level and pour concrete into the formwork. Once the concrete has hardened, the formwork is removed and the process begins again. The hydraulic system ensures that the formwork system remains stable and level as it climbs, which helps to ensure the quality and safety of the construction process. The working platform provides a safe and secure area for workers to carry out their tasks at high elevations, which can reduce the risk of accidents and injuries on the job site.

The system’s obvious advantages have been verified in plenty of projects both at home and abroad:

Not only in super high-rise buildings, but GETO hydraulic self-climbing formwork system is also widely used in the construction of bridges, dams, and other large infrastructure projects.

More specifically, GETO hydraulic self-climbing formwork is suitable for projects that require a fast and efficient construction process, as the system is designed to be quickly erected, dismantled, and moved to the next location. This makes it an excellent choice for projects with tight construction schedules, where time and labor costs are critical factors.

If you want to further inquire about the GETO formwork price list, please feel free to contact us!

Published: Feb 17, 2023

Last published: Jan 30, 2023

Under the background of carbon peak and carbon neutrality, China’s photovoltaic industry is developing rapidly. In 2022, the newly installed PV capacity and completed investment are significantly ahead of other power types, and the upstream industrial chain market continues to boom. BHI sorted out and summarized the PV industry chain related projects listed in the key projects of the provinces in 2022: 311 of 748 projects are planned to be built; The upstream silicon material and silicon wafer projects and downstream power generation projects are concentrated in the western region, and the midstream battery, module and auxiliary materials projects are the most in Anhui province.

1. New photovoltaic installations and investment lead the power industry

Since China officially put forward the goal of “carbon peak and carbon neutrality” in 2020, the investment in photovoltaic projects and the newly installed capacity have been further accelerated, and it has become the fastest-growing type of electricity. In the first 11 months of 2022, newly installed PV installations increased by 88.6 percent from the same period last year, while investment increased by 290.1 percent year-on-year.

2. The output and price of photovoltaic upstream industrial chain products increased significantly, and enterprises accelerated the layout

The rapid development of the photovoltaic industry has promoted a continuous boom in the upstream industry chain market. Especially since the second half of 2021, the output and market prices of major related products have seen rapid growth, and more and more enterprises have carried out or strengthened the investment layout in the photovoltaic industry chain.

The photovoltaic industry and upstream manufacturing market continue to boom, new investment by enterprises is active, and related engineering projects have become the focus of investment and construction in many places. BHI sorted out and summarized the projects related to the PV industry chain among the key projects in 26 provinces (autonomous regions and municipalities directly under the central government) in 2022, and a total of 748 projects were listed as the key projects at the provincial level, significantly higher than in previous years. A total of 311 projects are proposed, 115 of which are in the early stages.

GETO China company cooperated with a photovoltaic enterprise to enter this photovoltaic industry. GETO company recruited excellent sales personnel and provided systematic professional training to promote photovoltaic sales. In this way, GETO promotes the large-scale application of “solar energy + buildings” to promote rural revitalization and the construction of beautiful villages.

Published: Feb 17, 2023

Last published: Jan 30, 2023

As a result of dedicated research and development, the latest panel design of GETO – UT600 has its durability greatly improved from its previous version (U600). The tensile strength of the UT600 panel is equal to or more than 260Pa, while the bearing capacity is 60kN. The maximum deformation rate of using the GETO aluminium formwork system has been reduced by 15%, from 2.568mm max (U600) to 2.193mm max (UT600). As the outstanding China aluminum formwork factory, GETO devotes itself to technology innovation.

This indicates that the bulging possibility of the aluminium panel upon the completion of casting is lower, resulting in higher reusability of the aluminium formwork system on the sites. Contractors and project managers understand well that successful deformation rate control will contribute to significant project cost savings and reduction in on-site labour intensity. With a smaller deformation rate guaranteed, the verticality and horizontality of the casting results for time being is close to perfection, forming s right-angled and non-defective structure.

Meanwhile, horizontal structure bonds are attached to a pair of vertical structure bonds of every aluminium formwork panel by overhead welding. This welding technology is chosen to further strengthen the GETO formwork systems, as the welded area will be minimized and consequently creating less aluminium panel area to be affected by heat impact caused in case surface welding technique is adopted. This technology is tremendously significant for the production of aluminium formwork systems since welded area affected by the heat impact will result in the reduction of panel strength by half (if compared to the unprocessed formwork system). With overhead welding in place, lesser time is the cost for the welding stage in panel processing, contributing to lesser labour intensity in production, and lower processing cost.

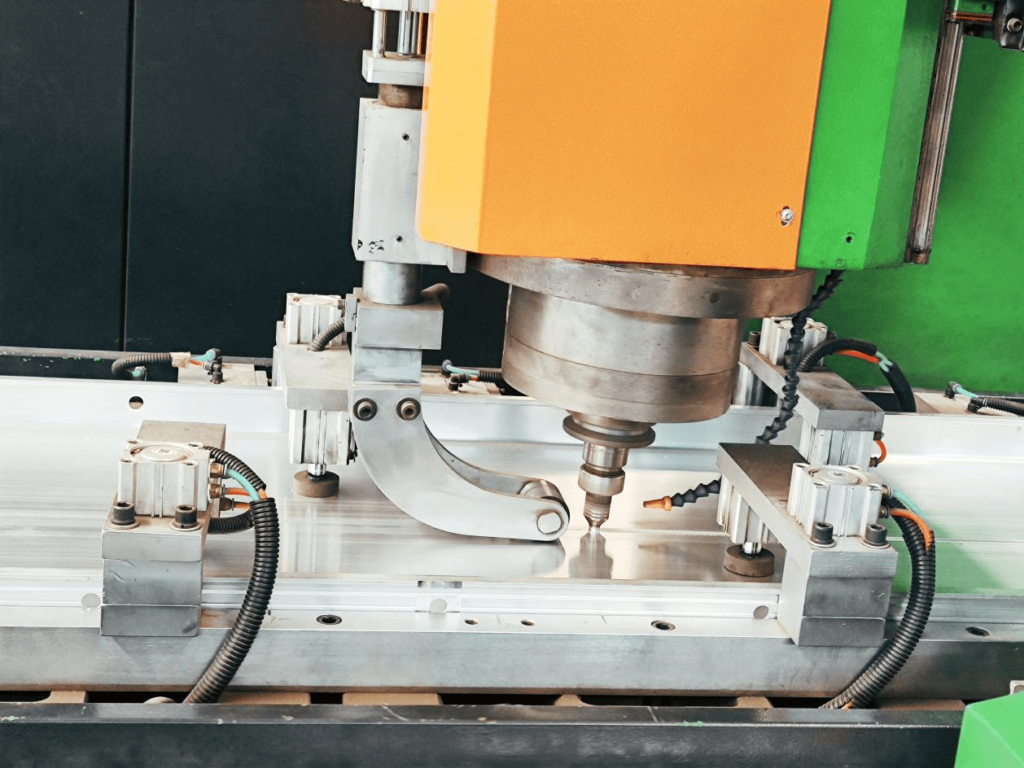

Friction stir welding is a solid-state joining process that uses a non-consumable tool to join two facing workpieces without melting the workpiece material. Its reliability and efficiency have been more and more widely acknowledged in a variety of industries. GETO is the first Chinese aluminium formwork manufacturer that applies such innovative technology in aluminum formwork production.

With friction stir welding to produce welds with very uniform mechanical properties but minimum distortion, GETO, providing a reusable aluminum formwork system, is so proud to provide customers with aluminium formwork of high durability and nice performance.

The mindful design and production technology of GETO aforementioned can deliver cost advantage to honorable clients, creating guaranteed high-quality and cost-controlled China system aluminium products.

Published: Jan 30, 2023

Last published: Jan 17, 2023

In the year of 2022, GETO, the “1+N” one-stop solution provider, has worked with international clients to create a series of excellent construction projects. We selected 12 of the most representative projects, let us take you to enjoy the charm of green and smart buildings.

The project is a 26-storey high-rise project in a prime location in Hung Hom, Kowloon, a masterpiece of large-scale integrated urban redevelopment.

Considering the high cost of labor resources in Hong Kong, GETO provides formwork solutions to improve construction efficiency and save labor costs.

Project highlights:

① Use the lightweight aluminium formwork, which is easy for construction team to assemble and disassemble the formwork system.

② Adopt the lifting shaft platform system. In the construction process, the lifting shaft platform system of the elevator shaft can be lifted layer by layer by tower crane, and can be retractable and reset, which made the construction of the elevator shaft become integrally and mechanically.

The T1210 Villa project is a large-scale housing construction project built by the local Housing Welfare Department, covering a total area of 628,000 square meters.

The traditional local construction habit is to use timber formwork.This project is the first introduction of aluminium formwork technology in the local housing construction field. GETO’s high-quality products and professional services have been highly praised by customers, and GETO also promoted the development of aluminium formwork construction technology in the housing construction market in this region.

Project highlights:

① GETO provides the design and construction scheme to maximize the utilization rate of aluminium formwork, including the mutual turnover of the different formwork sets and the mutual utilization of the mirror house type’s formwork;

② In the early stage of the project, in order to cooperate with the project approval of customers, GETO provides pre-design service for customers, and improves the design scheme by referring to the local architectural design code, so as to help customers get the approval smoothly.

The project consists of 11 buildings are constituted by 2,444 prefabricated modules in 91 structural types.

Project highlights:

① Considering the characteristics of the prefabricated unit in this project, which is used more times and has a variety of prefabricated unit structures, GETO and its partners jointly developed an automated and intelligent PPVC PRECAST HOUSING MOLDS, and made a detailed turnover plan and scheme of the formwork for the customer. Finally, client only used 35 sets of automatic PPVC PRECAST HOUSING MOLDS, 17 sets of non-automatic PPVC PRECAST HOUSING MOLDS and a small group of construction teams to complete the main structure construction of this gorgeous property!

② PPVC construction technology reduce the labor demand and labor cost of the construction site to the greatest extent, the high construction efficiency and convenient concrete pouring way obtain the customer’s praise!

San Ying Rapid Transit Station is a new rapid transit station planned and constructed by the Taiwan Government of China. This project is a special structure of the subway station, with a total of 8 floors and a large number of changes in each floor. Our company provides our customers with the aluminium formwork design scheme that maximizes the re-utilization of the old formwork and reduces the material cost of purchasing aluminium formwork for our customer.

Project highlights:

① Re-utilize the aluminium formwork of standard floor maximally to the rest of the changing floors;

② GETO’s design team spent 5 months in numbering the aluminium formworks one by one to solve the problem that the construction workers of the client had difficulty in finding the turnover of the old formworks during the construction process.

For the project with special structure and many changing floors, our company finally provided the perfect design solution, which was highly recognized by the customer!

Egypt’s El Alamein Ultra-High Complex project D01M is an important strategic urban core building in the Egyptian government’s Vision 2030 plan and another typical example of China-Egypt cooperation under the Belt and Road Initiative.

Project highlights:

① The project is a special shape structure, and there are arc-shaped floating plates with odd and even changes outside and the area is reduced layer by layer.

② The top panel of the project is prestressed panel, and the prestressed panel exists in a conflict between the prestressed system and the formwork system of GETO. At the same time, the customer requires to use their own ringlock scaffolding system in combination with the aluminium formwork of GETO. In response to the project situation, GETO provided a design scheme with a combination of aluminium formwork and timber formwork. The scheme was also highly praised by the customer!

Urban Village, a super high-rise residential project with more than 50 floors, is a new landmark of this country’s capital, and a large community where local new culture is most popular.

Project highlights:

① Spent 1 year in structural construction drawings docking communication, assist customers to solve the defects of the preliminary project construction drawings;

② GETO provides a design scheme which let two standard floors to share a set of aluminium formwork, re-utilize the changing floor formwork to the standard floor formwork, maximize the usage of formwork, to help customers save material costs.

③ This project has a duplex building structure, and the hollow floor in the structure is a big difficulty. GETO tailor-made a set of aluminium formwork support reinforcement scheme for the hollow floor for the customer.

④ The project finally completed the re-utilization of more than 10 floors of changing floors , achieve the maximum value of the usage of the aluminium formwork.

Occupy an area of 65 acres, D ‘Vine, the Malaysia’s 52-storey super high-rise apartment, is an affordable serviced apartment in a township mixed development in Kuala Lumpur.

Project highlights:

① The structure of the podium and the tower of the project is very different, and the storey height is not the same. Through the optimization of the building structure, GETO improves the standardization rate of the formwork, so that the standard and non-standard floors in the same building can use the same set of formwork system.

② In the turnover design of podium formwork, GETO provides aluminium-timber combination and formwork reinforcement scheme to help customers save materials and construction costs, and solve the pain point of high cost of non-standard formwork.

③ Aluminium formwork is used for the construction of a full set of structural buildings in the podium building, including the horizontal structure and column cap parts which are not commonly used aluminium formwork, and better pouring and forming effect was achieved.

The public housing is located at Lot B10, Zone A of Macao New City, covering an area of 6,831 square meters. The main uses include residential, public parking, commercial and public facilities. It is a social welfare housing.

Project highlights:

① Introduce advanced design ideas from other regions in the international market, actively communicate and cooperate with customers to overcome regional differences in technical specifications and construction habits;

② GETO uses the self-developed “BIM Industrial Design Software — Xiaozhi” to help customers with accurate formwork modulation. The technical advantages of automatic formwork modulation, correction and design, enable the aluminium formwork system of GETO to achieve ultra-high design quality without physical trial assembly.

The large residential project is a public tender of the Kaohsiung City government, a major focus of the housing and urban renewal Center in Taiwan, China.

Project highlights:

① The standardization rate of the formwork of this project reaches 85%, which greatly improves the construction efficiency and facilitates the mutual re-utilization between different block’s formwork.

② For the special points in the project, GETO helps customers to carry out special optimization and treatment: The installation of edge protective net enhances the security of formwork installation; The window sills are sloped to improve the water resistance of the house as a whole.

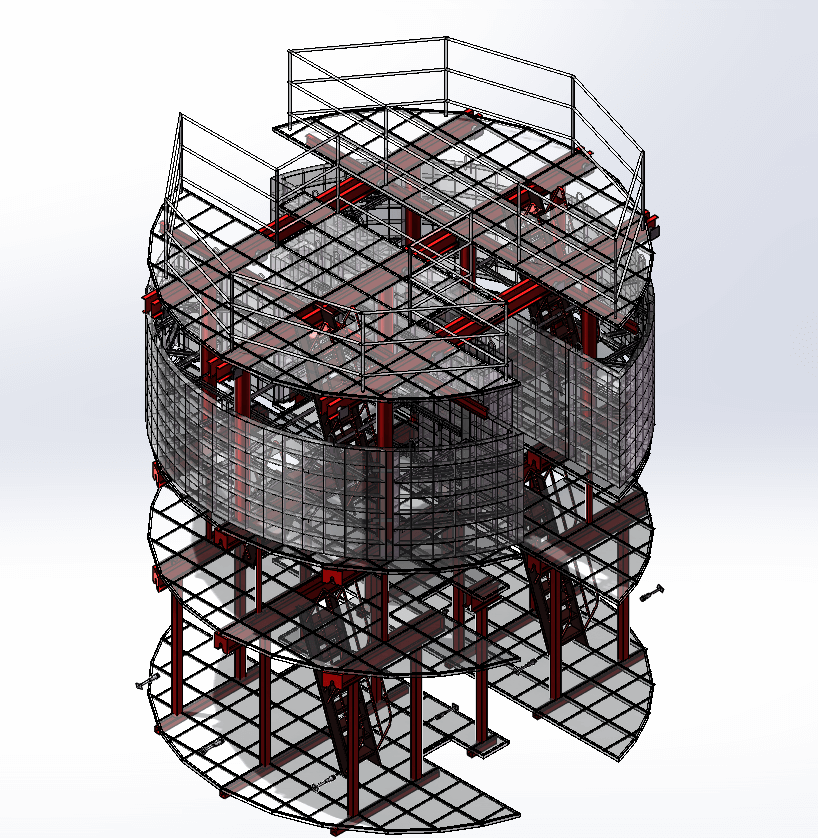

Conceived by PUB as a cost-effective and sustainable solution to meet Singapore’s long-term needs for sewerage collection, treatment, recycling and disposal, the Deep Tunnel Sewerage System (DTSS) is a signature public project of the Singapore Government. We were very fortunate to be involved in the DTSS2-T11 project as a supplier of shaft formwork and construction platforms.

Project highlights:

① The construction site of the project is under the shaft platform in the tunnel, and the construction space is too small to use large machinery. In order to solve the difficulty, the R&D team of GETO adopts the suspension construction scheme, installs the attached self-climbing system on the shaft platform, and realizes automatic climbing of mechanized equipment, reduces labor, improves construction efficiency, and solves the problem of narrow construction space.

② This project involves a large shaped circular steel formwork with an inner diameter of 13.5m, which is different from the general steel formwork reinforcement. GETO use the reinforced channel steel to make the steel formwork more firm and the forming effect better. At the same time, the large-shaped circular steel formwork manufacturing is also a major innovation breakthrough of GETO’s production technology.

③ The shaft construction platform is equipped with sensors and stoppers, and intelligent electronic control is adopted to ensure the stability of the frame structure and safe lifting.

④ Customized scheme design according to customer requirements: redesigned the special-shaped walkway plate, adjusted the height of the construction platform, and optimized the shaft platform model according to the force calculation.

This project is a serviced residential apartment project with a building area of 3,367 square meters, which is a typical hotel apartment in the area.

This is the first time for the client to use GETO’s aluminium formwork products for a hotel project. GETO is able to provide customized products and service solutions for different international markets.

Project highlights:

① The project is a complex re-utilization project, re-utilize another different structural type hotel’s formwork in this project. GETO carefully provides economic and technical solutions for aluminium formwork system, which not only saves cost for customers, but also meets the requirements of customers’ on-site construction.

② In combination with local design specifications and local construction habits, GETO has optimized the formwork structure for many times to meet customer needs.

IBN Highlands City is a multi-billion dollar landmark commercial project in Malaysia. It is located in the Genting Plateau, the largest summer resort in Asia. The project combines serviced apartments, a business district and a five-star hotel.

Project highlights:

① The project has great floor height, many changing floors with special and complex structures; including round columns, arc-shaped beams, decks with special angles, etc, special-shaped formwork accounted for more than 50%.

② GETO uses self-developed intelligent formwork modulation software to design and optimize the structure of the project’s formwork. Before the formwork delivery to the construction site, it has carried out several intelligent assembly tests in factory, which helps the project finally realize zero defects!

Published: Jan 30, 2023

Last published: Jan 17, 2023

This is the first formwork re-utilization project in Taiwan, China, which means most of the formwork are re-used from previous projects, with only a small portion to be provided additionally.

Such projects require substantial collaboration with customers, high accuracy in formwork re-design, and foresight of possible difficulties and counter plans. Limited time makes it even more challenging.

With close collaboration between both parties and construction work nicely orchestrated by our customer, the project is progressing well on schedule with quality outcome.

However, the consideration of formwork reuse does not merely start from the beginning of this project. Instead, it starts at the very beginning of the time. At the very beginning of the first project, the GETO design team communicates with the customer in detail about floor height, and structural features, also with an eye on all other projects in the customer’s project pipeline. This is to determine a versatile principle of formwork modulation for those projects, with a certain standardization rate that is mutually agreed upon. In the case of this customer, the standardization rate is set at more than 80%.

When the project is finished, the used formwork and aluminum formwork accessories are properly cleaned and stocked following GETO relevant guideline.

When it comes to a new project, in which the formwork is to be re-used, a detailed formwork list and zone-wise packing instructions will be given. It clearly tells what panels and aluminium formwork accessories shall be re-utilized, and specifies they are to be used in which room/zone. In this way, site workers don’t have to spend extra time searching for the right formwork piece. This is how a smooth and well-organized re-utilization of aluminum formwork can take place.

At GETO, we care more about how our customers could make the right investment, not only through providing reliable and quality products; but also by helping them activate their formwork stock to achieve the best value in utilization in the long term. GETO prides ourselves on our positioning as a trusted partner instead of a formwork vendor.

Published: Dec 30, 2022

Last published: Dec 17, 2022

Precast concrete staircases are made by casting concrete in a mold and then curing it in a controlled environment. This allows the staircase to be created off-site and then transported and installed on the construction site. Precast concrete staircases are commonly used in commercial and industrial construction.

To create a precast concrete staircase, the first step is to design the staircase and create a mold. The mold is typically made of wood or metal and is used to shape the concrete into the desired shape. The mold is then filled with wet concrete and allowed to cure in a controlled environment, typically at a precast concrete facility. Once the concrete has cured, the mold is removed and the staircase is ready to be transported to the construction site.

Precast concrete staircases have several benefits:

Overall, precast concrete staircases are a good choice for commercial and industrial construction projects because of their durability, strength, and cost-effectiveness.

Published: Dec 30, 2022

Last published: Dec 17, 2022