For too long, humans have lived in dysfunctional and polluted cities which is built by concrete and steel. A revolution in civilization is taking place, integrating the footprint of traditional cities and turning science fiction into reality. Designing to protect and enhance nature, Saudi Arabia spends $1 trillion on 170 km linear city “THE LINE”. The city that delivers new wonders for the world.

Can you imagine a city of 9 million people, covering only 34 square kilometers, only 200 meters wide, 170 kilometers long, and 500 meters above sea level? This means a smaller infrastructure footprint and city functions that operate at a higher level of efficiency than ever before. It’s a people-centered technological explosion that provides an unprecedented urban living experience while protecting the surrounding natural environment as much as possible. It reshapes a new concept of urban development and maps out the future of urban innovation.

Progressive design allows residents to walk just 2 minutes to nature, which is spread out over open space of different levels. The ideal climate year-round so residents can enjoy the surrounding nature at any time. A 5-minute walk to all amenities and a high-speed rail line to keep end-to-end trips under 20 minutes. The automated services are powered by artificial intelligence.

No roads, cars or emissions, 100% clean energy, zero carbon emissions in the city, 95% of the land will be designated as a nature reserve.

Published: Dec 17, 2022

Last published: Nov 30, 2022

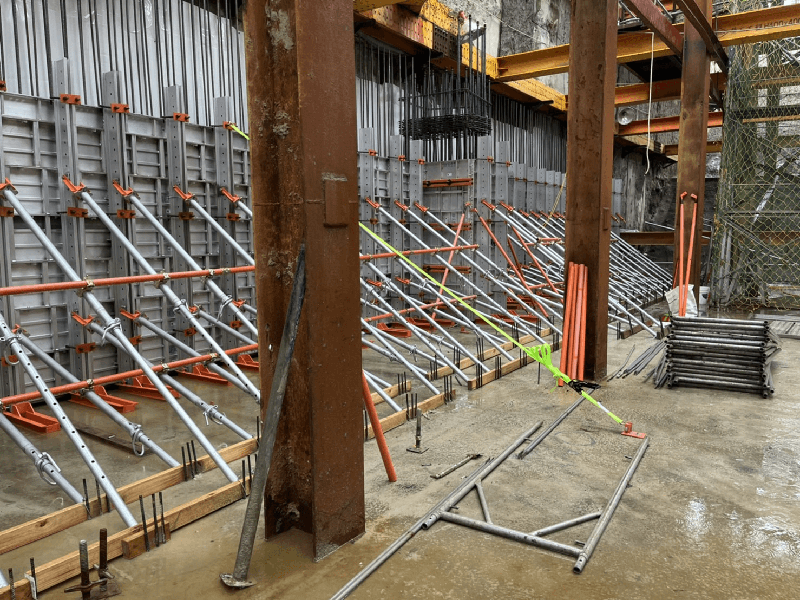

As we all know, transport is of great importance to both social and economic development. In Taiwan, China, new MRT stations are being built for the public’s benefit and convenience. GETO is proud to have been involved in one of these projects supplying construction materials. We supplied aluminium beam formwork, aluminium wall formwork, aluminium deck formwork, and aluminium column formwork, single-side formwork is also included.

When it comes to retaining walls, we usually use large triangular trusses to build them. However, the large triangular trusses are so large and heavy that they must be lifted and moved by crane and cannot be installed by manpower only. A bar implant solution is relatively light but requires more pre-set operations. The client gave us their ideas, wanting to be able to install it manually without using the crane, not a tie rod embedding plan, and to use aluminium formwork for the construction. Our international R&D team finally provided an Aluminium Beam Type Single-Side Wall Framework solution, which not only meets the customer’s requirements for manual operation and less implant as mentioned above but also increases the turnover utilization rate of each component, as aluminium beams and props components can be used in other floors and structures after the retaining walls are done.

Thanks to the joint efforts of the client and us, the formwork was installed with a high degree of completion and the finish was quite satisfactory. The customer has actively provided us with feedback on the use of the product on-site, which has helped us to continue to optimize the product and meet the requirements of the site. In addition, Single-Side Wall Framework can be used for wind energy farm construction.

GETO also provides a Triangular Truss Type Single-Side Wall Framework. Two types of single-side wall formwork each has its advantages with aluminum beam type single-side support formwork.

Published: Nov 30, 2022

Last published: Nov 17, 2022

The foundation is the load-bearing structure below the ground level of the building, whose function is to bear the loads transmitted from the upper structure of the building and transfer them to the subsoil with its weight. If a house or high-rise building does not have a solid foundation, the top part of the building will not be well supported, so the house may be unstable or even collapse, which is extremely dangerous.

A solid foundation is essential for a solid super high-rise building. Any such problems as instability and collapse can be prevented by taking some measures. Stability is crucial for a solid foundation. An unstable and unsolid foundation can cause irreversible structural damage or even worse.

Soil inspection before construction is easily overlooked, and the instability of soil conditions will lead to the instability of future foundations. In fact, before starting any work on the ground, it is necessary to carefully check the condition and type of the soil.

During foundation excavation, make sure there are no small stones, rocks, pebbles, branches, or roots on the ground. When grading the soil, a specific level of slope must be maintained by removing the waste material. The ground should only be dug to the required depth.

To start building the foundation, the footings must be installed. To make the concrete stronger and crack-resistant, the footings also need to be reinforced. Concrete should be poured without any air gaps, as this will cause even more cracks in the foundation.

Finally, smooth the top layer of the foundation with concrete finishing tools such as hand floats and trowels.

The following project photo shows how GETO aluminium formwork builds foundation and foundation walls. GETO provides one side of panels to the foundation, some customers require using alu-forms to foundation walls, thus two sides of panels will be needed. As there are holes in the surface of aluminum formwork, the use of square tubes and brackets can be reduced when building the foundation. The steel bar is inserted into the soil of the ground through the holes in the panel so that the panel can be fixed without displacement. It’s a cost-effective solution. It not only ensures the stability of foundation construction but also reduces on-site materials and labor costs.

Reference:

https://dailycivilfacts.com/better-building-foundation-and-its-failure/

Published: Nov 30, 2022

Last published: Nov 17, 2022

The 132nd China Import and Export Fair (Canton Fair) started on October 15, 2022. This Canton Fair is held online, attracting more than 35,000 exhibitors and many buyers to gather the event. These exhibitors cover 16 categories such as Electronics and Household Electrical Appliances, Lighting Equipment, Hardware Tools, Building Materials, Consumer Goods, Home Decorations, and so on. GETO also participated in this online Canton Fair and gained a lot.

During the online exhibition, GETO made dozens of online demonstrations. We are excited to welcome over 4k+ likes from incoming leads to join our showroom and received many electronic business cards from purchasers.

At the same time, from Oct. 1st to Oct. 31st, GETO specially launched sales promotions for overseas projects (excluding the Chinese mainland). All customers can participate in this promotion, and they will have the opportunity to get free aluminum formwork accessories discount, a top panel sample of aluminum formwork, and coupons, which have received an overwhelming response.

During the exhibition, GETO was successfully selected as one of the “Selected Enterprises” at the Canton Fair, which means GETO’s company performance and qualifications have been officially recognized.

-1024x496.png)

The performance of the ASEAN market at this Canton Fair is very eye-catching. China Business News Network launched a special report “Two-way Running, China-ASEAN Continues writing ‘Canton Business’Story”. Manager Lei of GETO International Marketing Department said in an interview: “At this Canton Fair, the ‘Belt and Road’ and ‘RCEP’ and other favorable benefits have attracted many ASEAN customers’ inquiries. The autumn Canton Fair has become a ‘booster’ for us to explore the ASEAN market.”

GETO New Material focuses on new-type aluminium building formwork, self-climbing platform, and assembly precast concrete(PC) components. We always adhere to the customer-focused and result-oriented operation philosophy and are committed to promoting low-carbon green buildings and improving residential life quality. In the future, we will create a whole industrial chain system based on information by using big data, artificial intelligence, and Internet of Things technologies. GETO actively promotes the transformation and innovation of traditional buildings into green and intelligent buildings.

Contain Fair is a “bond” of friendship and a “bridge” of trade. This online Canton Fair exhibition will continue until March 15, 2023, GETO showroom sincerely welcomes your visit!

-1024x409.png)

Published: Nov 17, 2022

Last published: Oct 30, 2022

The BAKER CIRCLE.DOVER project is a 26-story high-rise residential project. Located in Kowloon’s prime location of Hung Hom, “BAKER CIRCLE” spans a total commercial and residential floor area of over 1,000,000 sq. ft.2, standing as a large-scale comprehensive urban redevelopment masterpiece that is rarely seen in the past 30 years. The project uses GETO combined aluminum formwork and precast concrete(PC) components for integrated construction, helping the Hong Kong construction industry to transform and upgrade to industrialization, intelligence, and green.

-1024x576.png)

-1024x576.png)

Linked up with several major roads, this redevelopment incorporated its own brand-new 3-dimensional shopping streets, created with concepts of sustainable environment, world-class architectural and design aesthetics, cutting-edge smart living gadgets, and a wealth of innovative clubhouse facilities. “BAKER CIRCLE”1 is set to redefine the ideal contemporary lifestyle.

The project is equipped with four sets of steel supports (five sets of the cantilever), and the construction speed of the workers on the construction site can reach four days per floor. Compared with traditional formwork, the project construction period is greatly reduced and great value is created for customers.

The average daily wages of construction workers in Hong Kong are extremely high. GETO provides professional guidance on installation services to improve the efficiency of aluminum formwork installation for on-site personnel. It also shortens the construction period, which can significantly reduce the labor cost of workers.

The turnover of aluminum formwork in this project is more than 20 times, and the construction of all standard layers can be completed by using one set of aluminum mold, with a low average cost of use.

The aluminum alloy formwork system with an average weight of 25KG/㎡is simple and convenient to assemble. It is completely assembled by hand and does not require the assistance of any mechanical equipment. Workers usually only need a small hook and a small hammer for construction, which is convenient and fast. Skilled installers can install 20-30 square meters per person per day. Compared with wooden formwork, the advantages of aluminum formwork are more obvious. Aluminum formwork installers only need 70-80% of wooden formwork installers, and there is no need for skilled workers, as long as simple training is given to the construction workers before installation.

After the aluminium formwork system is assembled, it forms a whole framework with good stability. With the reasonable arrangement of load-bearing pillars, the bearing capacity can reach 30KN per square meter.

After concrete casting and removing the formwork, the surface of the concrete is smooth and clean, which can meet the requirements of finishing and fair-faced concrete without plastering and can save plastering costs.

The aluminum mold uses renewable materials, which can effectively help energy conservation and emission reduction. It is a green building material. At the same time, the project’s prefabricated laminate panelsand prefabricated stairs reduce the generation of construction waste on the site.

The project also used the GETO Shaft Platform and successfully helped solve the pain points of the customer and improve construction efficiency. The lifting shaft platform system can be lifted layer by layer through a tower crane. The whole system can be reset by contraction and expansion, which makes the construction of the lift shaft holistic and mechanistic.

Shaft Platform solved pain points :

.png)

Published: Oct 30, 2022

Last published: Oct 17, 2022

The Biden-Harris Administration announced $30 million from President Biden’s Bipartisan Infrastructure Law in funding wind energy research and development projects to reduce the cost of onshore and offshore wind energy projects which benefit communities across the country. Wind energy accounted for more than 9 percent of total domestic electricity generation in 2021 and will play a significant role in achieving President Biden’s goals of 100 percent clean electricity by 2035 and a net-zero economy by 2050.

“Wind energy is abundant, affordable, and already powers 40 million homes”, said the U.S. Secretary of Energy “But that’s just the beginning – wind power is experiencing explosive growth. Thanks to President Biden’s Bipartisan Infrastructure Law, the Department of Energy is helping to break through technical barriers and accelerate the deployment of this affordable resource across the country.”

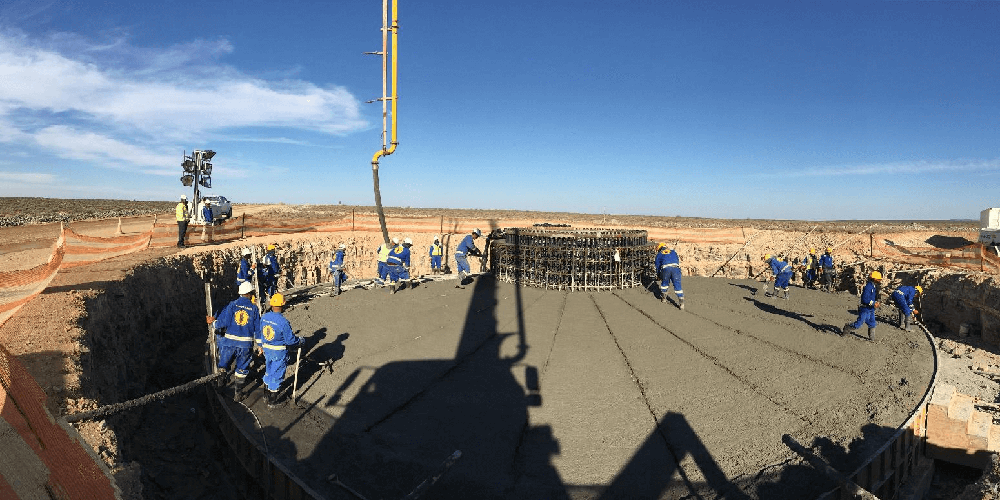

Wind energy is one of the clean energy resources. It has become increasingly popular in various countries around the world over the years. And the transformation of wind energy depends on wind farms. For the construction of wind farms, the most important is the foundation of the wind turbine. Foundation construction uses cast-in-place, being divided into 3 different pouring stages. Thus, high quality and safe single-side wall framework system is required for foundation construction. GETO, as one of the best aluminium formwork companies which helps promote green building development, after comprehensive consideration of market demand and safety performance, successfully developed a safe, environmentally friendly, and convenient single-side wall formwork.

GETO single-side formwork is a standard formwork supporting bracket system for reinforced concrete, which is specially designed for transferring fresh concrete side pressure to support frame and concrete foundations, without any tie rod being pulled through the wall. It is mostly used in building construction that has strict waterproofing demand and can not be strengthened by using a tie-rod system.

Up to 7.5 meters of concrete casting height with a single cast.

Suitable for different wall heights with different support frame sizes.

In subway stations, sewage treatment plants and other excavation projects.

For more details about GETO Single Side Formwork, please contact geto_market@geto.com.cn

Reference:

Published: Oct 30, 2022

Last published: Oct 17, 2022

Working at heights can be extremely hazardous, especially for the construction workers who are in charge of the construction of the skyscraper externals. Falls from height (FFH) have been a leading cause of fatal accidents among construction workers. Safety is always the top priority among project management teams in the construction industry. However, traditional buck scaffolding can’t protect the safety of construction workers. Modern scaffolding that can guarantee workers’ safety is urgently needed.

Any fatalities that happen in the construction sites recognized as highly risky will lead to significant economic loss by up to 15%. The affected construction project management team will bear a significant risk of lost project execution time because of the investigation of a construction accident. In addition, they need to increase more re-training for new hires and workers and deal with compensation for injury and death claims.

The failure of construction companies to maintain a well-safe management system in their organization is a major cause of accidents or falls from heights. This issue is common in the construction industry in multiple countries worldwide. Today’s project construction is obsessed with the speed of construction, which also increases the rate of safety negligence of workers on the site. At the same time, most accidents occur on working platforms or a framework scaffold. Therefore, there is an urgent need for a protective construction platform with high safety performance.

Acknowledging how detrimental are the hazardous effects of falling from heights, GETO, as a high-quality aluminium formwork and self-climbing platform supplier, promotes the use of self-climbing platform system over the traditional scaffold system. The self-climbing platform is a technological innovation in the field of scaffolding, with features that provide greater safety against workers and objects falling from heights. Meanwhile, the self-climbing platform is equipped with a controlled synchronized climbing device, which requires only a single installation of the system at a low level.

The self-climbing platform system is a perfect match for the aluminum formwork system in the construction of super high-rise building projects. Therefore, it is advisable for contractors to choose a supplier who can provide an integrated system of self-climbing platform and aluminum formwork system. So, How to Choose Aluminium Formwork and Self-Climbing Platform Supplier? GETO’s self-developed intelligent BIM system enables GETO’s design team to consider how the self-climbing platform and aluminum formwork for concrete should be designed to meet customized projects requirements proposed by clients and to avoid potential conflicts that may occur when the two systems are used on-site to ensure the project runs smoothly.

To date, GETO Malaysia has participated in multiple construction projects with aluminum formwork and self-climbing platform integrated into use. One of the featured projects that combine the use of both innovative systems is Agile Embassy Garden, a regionally renowned skyscraper project that adopts GETO’s 139 sets of self-climbing modules for the construction of concrete structures and architectural construction of its three towers.

Reference:

Muhamad Zaini, N. M., Mat Salleh, M. A., Hasmori, M. F. & Abas, N. H. (2020). Effect of accident due to fall from height at construction sites in Malaysia. IOP Conference Series: Earth and Environmental Science, 498. doi: 10.1088/1755-1315/498/1/012106

Published: Oct 17, 2022

Last published: Sep 30, 2022

GETO Malaysia participated in a significant landmark project in the middle of Genting Highland, wellknown summer retreat in Malaysia. It is IBN Highlands City – A billion-dollar project developed by IBN Corp Ltd. GETO empowers the construction industry around the world with high aluminium formwork productivity.

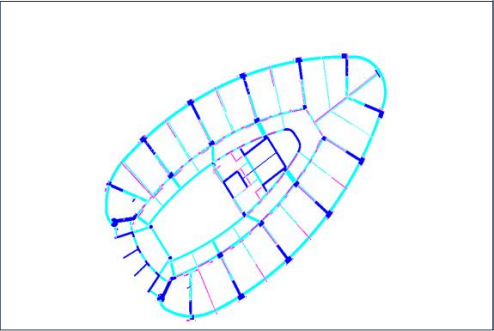

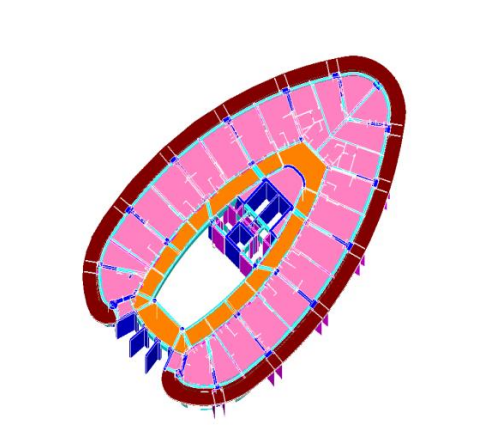

IBN Highlands City is a mixed development project (serviced apartment and hotel), which was designed based on the imaginative visuals of several pieces of flower petals placed in the midst of clouds of the cooling highland. The project has a total built-up area of 8,400,000 sq ft.

Within the 4978.52 ㎡ aluminium formwork construction area the project consumes in total, GETO Malaysia supplied 2166.83 ㎡ of the aluminium formwork system. In the system, GETO Malaysia supplied 400 ㎡ systems, which are round edges and arc-shaped columns. The special design of IBN Highlands City that is largely different from common typical structures creates challenges for the construction and precise design of formwork in aluminium factory for the project.

With GETO’s intelligent formwork software, BIM Modulation Design in place, special structures are no longer a real challenge since every structure in the AutoCAD drawing of IBN Highlands City can be quickly checked in place at one time. This patented software of GETO Group can automatically identify walls, beams, slabs, and other structures with 100% precision attained.

In addition, GETO’s intelligent BIM Modulation Design Software can facilitate the client to achieve an ideal state in maximizing the reusability of the client’s existing aluminium panel in adoption together with the GETO aluminium formwork system.

Upon the delivery of the aluminium formwork system to the site, GETO site supervisors stayed with the project for at least one month. They are committed instruct the workers on site to appropriately fix the structure system, while quickly responding to any circumstances related to the formwork system on-site. Because of our outstanding construction engineering solutions, we have done a great job with this project.

Besides the use of the standard panels supplied, the curve-shaped structures formed by special-shaped aluminium formwork systems are in good casting effect as well. This helps the contractor to save up time for crafting the special-shaped by crafting timber formwork on-site, which brings the result of cost-saving in hiring increasingly costing labour in carpeting. Also not forget to highlight, the high durability of the GETO Aluminium Formwork System guarantees the consistency of the casting quality of the project across numerous floors it is being reused.

Published: Sep 30, 2022

Last published: Sep 17, 2022

The 132nd online Canton Fair will start from October 15, 2022. We sincerely invite you to participate in the online exhibition. Please scan the QR code below to start the online Canton Fair. At the Online Canton Fair, we will release our products in the exhibition hall and do live stream. In addition, this article is written to introduce how to get discounts and the GETO preferential policy of this sales promotion activity in detail.

GETO, a share listed company (stock code: SZ 300986), focuses on new-type aluminium formwork, self-climbing platform, assembly precast concrete (PC) components with civil and public construction fields covered. Now GETO has developed PPVC precast housing molds, quick-deck system, single-side wall framework, table formwork, shaft platform and other products that meet the market demand.

GETO specially launch Sales Promotion for overseas projects (excluding the Chinese mainland). Register from October 1, 2022 to October 31, 2022 you can get preferential entitlement, and enjoy the preferential discount.

Share your code to get better prices. Scan the QR code, generate your invitation code poster, share it with your friends, and enjoy better prices.

Scan the QR code to register, you deserve the best prices, get it today!

WeChat and Google are supported

a. Discounts from this activity and discounts from other activities of our company cannot be used together. If you get discounts from two or more activities, you can choose discounts from only one of these activities.

b. Each of the following discounts can be used once only.

You can enjoy the discount one only when signing the contract with GETO between November 1, 2022, and January 31, 2023. Besides, you need to choose only one to enjoy from the following A or B or C of discount one.

a.1 When you purchase aluminium formwork or self-climbing platform with the price of USD 300,000 (including 300,000) or above, GETO will return a USD 900 coupon, which can be used to purchase building construction and decoration products.

a.2 When you purchase aluminium formwork or self-climbing platform with the price of USD 600,000 (including 600,000) or above, GETO will return a USD 3,000 coupon, which can be used to purchase GETO building construction and decoration products.

b.1 You need to purchase the whole set of aluminum formwork system;

b.2 When you buy aluminium formwork area for more than 2000㎡, we will give you a model room (about 14㎡, excluding stairs) for every 2000㎡.

c.1 You need to purchase the whole aluminium formwork system;

c.2 When you purchase aluminium formwork accessories worth over USD 2500 (including 2500), the total price will be reduced by USD 150 directly.

c.3 When you purchase aluminium formwork accessories worth over USD 7,000 (including 7,000), the total price will be reduced by USD 500 directly.

c.4 When you purchase aluminium formwork accessories worth over USD 10,000 (including 10,000), the total price will be reduced by USD 1,000 directly.

a.1 This giveaway is only available to new customers (your company has no contract history with GETO);

a.2 If you confirm that receive this sample, you need to pay the freight.

a.3 The top panel sample we provide is limited to the top panel 600D1200;

The inviter can enjoy this benefit only when the invited client scans the QR code and fills in the exclusive invitation code of the inviter.

a.1 When your invited client purchases the GETO products worth USD 300,000 (or above) between November 1, 2022, and January 31, 2023, you will receive a coupon worth USD 900;

a.2 The coupon can be used to purchase any product of GETO and have no expiration date.

b.1 When your invited client purchases the GETO products worth USD 600,000 (or above) between November 1, 2022, and January 31, 2023, you will receive a coupon worth USD 3000;

b.2 The coupon can be used to purchase any product of GETO and have no expiration date.

Published: Sep 30, 2022

Last published: Sep 17, 2022

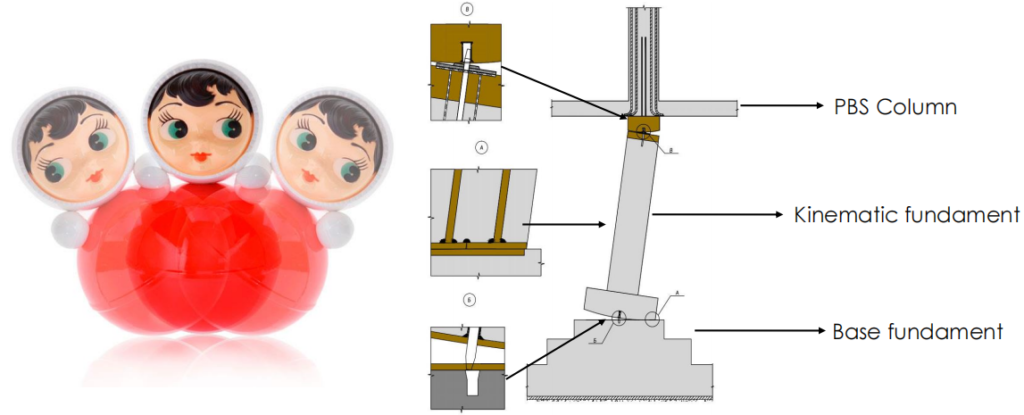

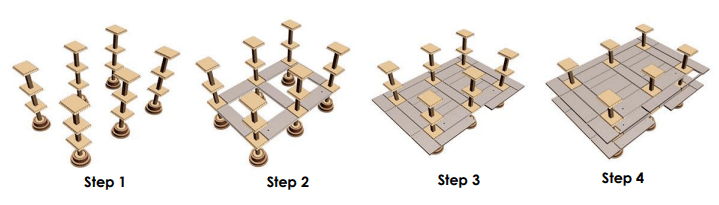

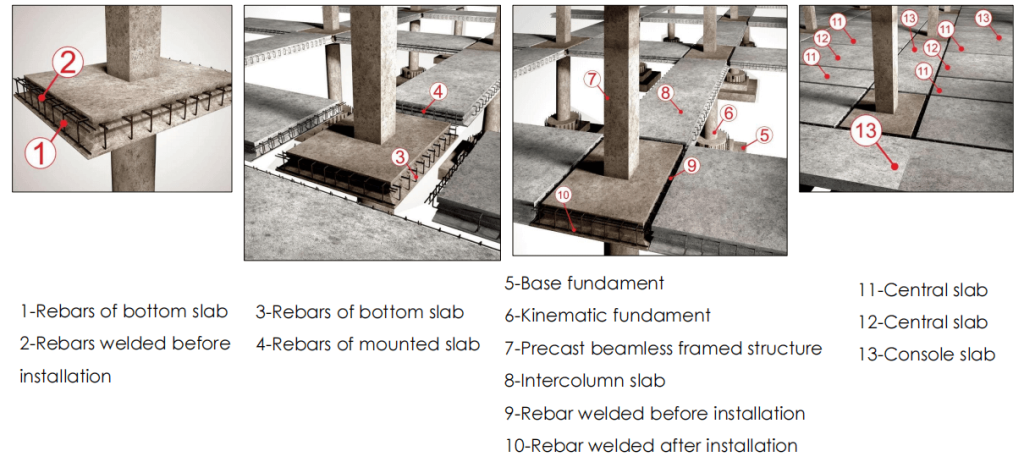

One of GETO’s customers has studied special building structures to protest against earthquakes. Their company mission is to provide solutions to save lives and deliver affordable housing in earthquake-prone areas. Finally, the local government highly appreciated and recognized their building solution, which adopted the GETO Precast Concrete.

Seismic isolated fundamental work on the same principle as a“tilted doll”. Unlike other seismic isolation system, it doesn’t require any regular maintenance. GETO Precast Mould System helps clients save a lot of money for later maintenance.

The clients provide the architectural plan, elevation plan and section only, there is no structural plan, because it’s beamless structure. However, they require us to provide aluminium forms for the column parts. it’s not the same as normal square columns. The difference is that we need to reserve several holes for steel rebar and those holes should be open precisely, here let me share some attached photos from GETO precast factory. Our customer calls it as “PBS” column.

This precast formwork system has two main components that can be used independently. The factory produced precast columns and precast slabs are combined and welded on site. No beams are required that reduces building weight, cost and time of construction.

Published: Sep 17, 2022

Last published: Aug 30, 2022