Recently, the Ministry of Finance, the Ministry of Housing and Urban-Rural Development, the Ministry of Ecology and Environment and the General Department of the National Energy Administration jointly issued the Notice on Organizing the Application of Clean Winter Heating Projects in Northern China, in order to further expand the scope of support for clean winter heating in Northern China and continuously promote greens development. Building carbon peak, carbon neutral,The integration of photovoltaic, light and heat building is the only way. GETO, a green building materials company, will adhere to the China development strategy and contribute our effort to China’s green development.

There are two application forms of the combination of solar energy and building energy saving, one is BIPV (Building Integrated PV); One is the thermal buildings.

Song Dengyuan, chief technology officer of Yingli Group and director of the State Key Laboratory of photovoltaic Materials and Technology, introduced that BIPV products are not simple photovoltaic panels, but new green building materials that can generate electricity, which is highly consistent with the demand of energy-saving buildings in green building materials.

Wang Xinrong, chairman of Beijing Wadineng Technology Co., LTD., said that the thermal building is the roofing system or metope system made up of light and heat components, through absorbing solar radiant heat, for domestic hot water supply and winter building heating, can also become a major direction of existing building transformation in our country.

From the development trend of the whole industry, both internal and external factors are very supportive of the deep combination of the construction field and the utilization of solar energy. In the near future, the integration of the construction and photovoltaic, light and heat is the only way.

GETO company also has the plan to enter this photovoltaic industry, to promote the large-scale application of “solar energy + buildings” to promote rural revitalization and the construction of beautiful villages.

Reference:

http://www.bhi.com.cn/Sector/Detail.aspx?id=42163093

Published: Sep 17, 2022

Last published: Aug 30, 2022

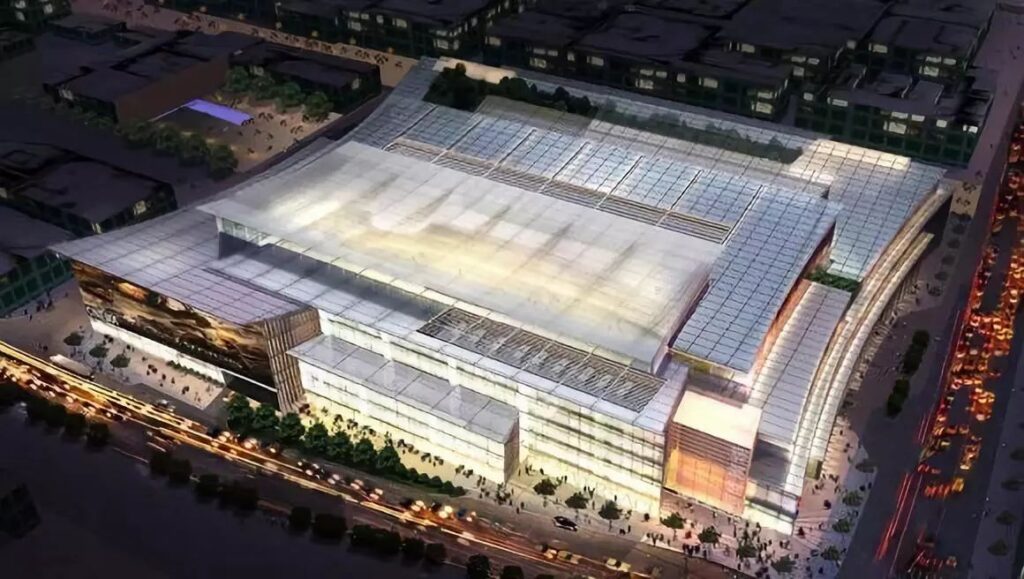

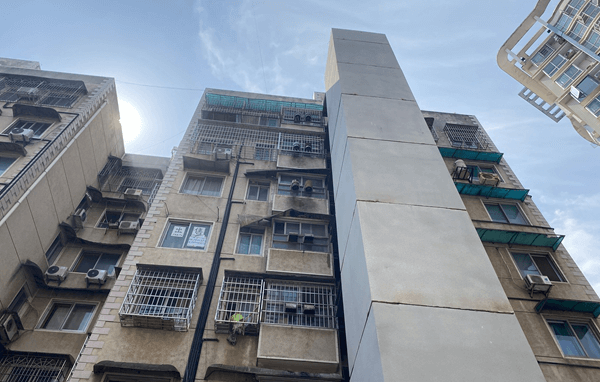

In Taiwan, China, the government is planning new MRT stations, of which the Sanying MRT station is under construction. GETO has proudly supplied aluminium formwork system for wall, beam, deck, column etc, including inclined columns.

The dimensions of the largest inclined column on site are as follow:

Length of column base section: 2300mm

Width of column base section: 2300mm

Vertical height of column: 14253mm

Length of beveled side of column: 15222mm

Angle: 69.45°

MRT are closely related to people’s lives and being able to build MRT stations with aluminium formwork is an important step forward in GETO’s involvement in public construction projects in Taiwan.

In this project, due to the special structure, it is necessary to adopt large leaning columns, which are more difficult for our aluminium formwork design, but we did it perfectly.

Large leaning columns mean that stronger support and reinforcement systems, more accurate design and production, and strict site management are required – all three of which are essential.

① GETO solves it with tie rod system, which ensures the security and efficiency of the project. GETO formwork class products can be applied to different project types and high turnover of formwork between different structure types and typical floors can be achieved.

② GETO uses self-developed software of modulation, such as BIM, Auto CAD and 3D Modulation Software to offer the clients. These technologies provide technical support for the customer’s project, promoting it to be successful.

③ In this project, GETO provides 24 hours online technical support for customers to solve the technical problems when using our aluminium column formwork, so as to be customer-center and give customers a good experience.

Published: Aug 30, 2022

Last published: Aug 17, 2022

There are many precautions for building a formwork installation. These precautions will be analyzed from the perspective of the cleanliness of the construction formwork, the pre-buried holes of the formwork, the formwork release agents, the splicing of the formwork, and the support force, which will largely affect the effect of the casting of concrete. In addition, if you choose aluminium formwork, these matters above will be easier.

Sundries left in the formwork will cause defects such as slag inclusion in the concrete. If the aluminum formwork is used, which can be recycled many times, some concrete blocks will stick to the aluminum formwork after repeated casting. If it is used without cleaning, the concrete after casting will become bumpy. Therefore, the residual concrete blocks on the aluminum formwork shall be removed in time.

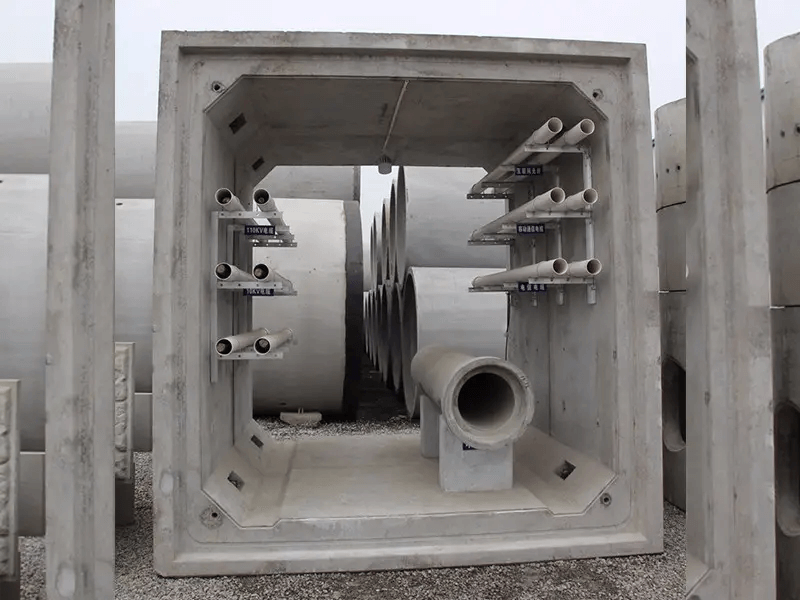

2. Make preparations for embedded parts and pre-buried holes

When supporting the building formwork, the embedded parts and pre-buried holes on the building formwork shall be fixed at the same time. The embedded parts and pre-buried holes shall not be left, the dimensions shall meet the requirements, and the installation shall be firm. At the same time, different formworks have different ways of installing embedded parts and pre-buried holes. Wooden boxes are nailed on the floor slab for the construction of wooden formworks to pre-buried floor holes. However, this method is not feasible in the construction of aluminum formwork, and it is difficult to fix the casing or pre-buried hole model on the aluminum formwork. As the assembly of aluminum formwork is a programmed assembly, it is not allowed to open holes on the formwork at will. As a result, the pre-embedding of the wire box and the wire pipe must be planned and designed in advance, and the position and direction must be accurate. Therefore, when choosing aluminum formwork suppliers, we shall choose professional and high-quality suppliers, such as GETO, an aluminium formwork company that provides intelligent and customized design services and 24/7 site engineering services.

When selecting the formwork release agents, select the release agents that do not affect the structure and hinder the construction of decoration works. At the same time, since the formwork release agent may pollute the joints between the reinforcement and the concrete, it may have an obvious adverse effect on the mechanical performance of the concrete structure. As a result, it shall be avoided polluting the reinforcement during brushing. On the other hand, it is also necessary to brush a sufficient amount of formwork releasing agents. If the formwork release agents are not brushed enough, a large amount of concrete will stick to the formwork. It should be noted that the formwork release agents may be washed away after rain, so it must be ensured that the release agents are brushed in place before casting.

If the joint of the building formwork is not tight, it will lead to the leakage of the concrete. The leakage of concrete will result in the honeycomb surface of the concrete appearance and directly affect the quality of the concrete. Therefore, no matter what materials of formwork are used, the joints shall be tight. It is worth noting that the aluminum formwork has few joints, high precision and good concrete surface effect after formwork removal. After the aluminum formwork is removed, the concrete surface quality is flat and smooth. There is no need to plaster, resulting in making construction more cost-effective.

For a multi-layer cast-in-place structure, the upper building formwork must be supported on the lower concrete slabs. There are three points for attention. First, the lower concrete floor shall have sufficient bearing capacity, and support shall be added if necessary. Second, the columns of the upper and lower supports shall be aligned. Third, the base plate shall be laid under the column of the support.

All in all, there are many complicated matters needing attention in building a formwork installation. Moreover, by choosing a good formwork supplier, we can avoid these unnecessary troubles to some extent. In order to choose a formwork supplier with high-quality services, we can refer to a good article called How to Choose Aluminium Formwork and Self-Climbing Platform Supplier? written by GETO, a high-quality aluminium formwork company.

Published: Aug 30, 2022

Last published: Aug 17, 2022

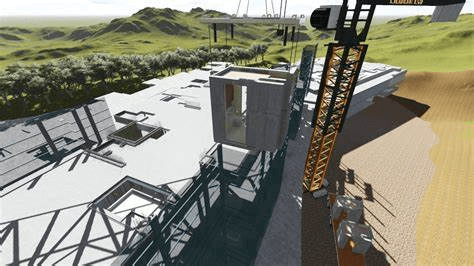

A startup construction company——Vantem manufactures high-efficiency, net-zero modular architecture at competitive costs and low carbon. The company recently raised a Series A round of investment from the Bill Gates-founded firm. Net-zero architecture, buildings that produce as much energy as they use, are typically cheaper to own than standard housing. Still, they often involve high construction costs since they require advanced building technologies and engineering. They aim to change this dynamic by employing modular construction technology.

The modules are built of large structural panels. The architecture, with proprietary technology, has built-in high insulation, providing an efficient thermal envelope. The panels are made from refractory materials, making them resistant to high temperatures and protecting the structures from fires. The company reports that the resulting modular units are hurricane and earthquake resistant. This modular systems simplifies construction and reduces costs and delivery times while also being well-suited for a wide range of regions and climates.

The company first launched in South America and the Caribbean. After an extended period of testing, code approval, and building proofs of concept, it has deployed its system in over three million square feet of living space in countries such as Uruguay, Brazil, Bolivia, Chile, Colombia, and the Caribbean. The company partners with local developers at each location to build new factories. The company plans to build 15 factories in the U.S. over the next seven years, each capable of producing a million square feet of dream homes each year.

The world annually adds approximately 51 billion tons of greenhouse gases to the atmosphere, trapping heat and driving up global temperatures. The only way to avoid the worst impacts of climate change is to stop adding greenhouse gases by 2050. The company is founded on the belief that innovations in all industry fields are the solution to replacing the greenhouse gas-producing tools, we currently rely on with a new set, powerful enough to give everyone in the world access to clean, reliable, and affordable energy.

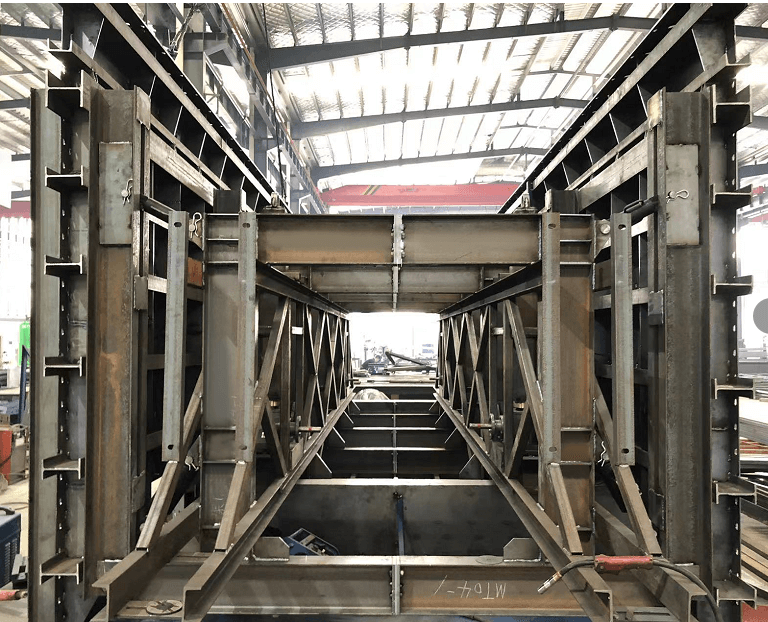

① Lower labour cost. Extendable steel structure and automated control system can replace manual operations with machinery and it saves up over 40% of labour cost.

② High construction efficiency.GETO Precast Mould System casts all the structure of the building at once, including the deck, side walls, bottom plate, doors and windows, thereby reducing the overall time to form the prefab structure. Compared with the traditional steel formwork, the on-site efficiency is increased by more than 50%, providing customers with efficient products and services.

③ Environmental protection products. GETO Precast Mould System conforms to the world’s green and low-carbon trend. GETO practices the trend of global low-carbon economy and the green building concept advocated by governments around the world, and puts the concept into practice in its products and services. PPVC Module technology is gradually replacing traditional building technology, adding power to the world’s environmental protection cause.

All in all, GETO adheres to the business philosophy of “customer-centered, result-oriented”, and is committed to providing clients with high-quality products. GETO takes the initiative to assume social responsibility and innovates products in line with the world’s environmental philosophy.

Reference:

Published: Aug 15, 2022

Last published: Jul 30, 2022

It’s crucial for a project to choose a

There are two requirements for using aluminium formwork. First, the shape and structure of the building are simple. However, some powerful

Second, aluminium formwork is suitable for buildings with more than 20

The aluminium formwork system is safe. Aluminium formwork forms a whole through pin and wedge, hollow section, tie rod or flat tie, wall bracket, and other

Considering there are special structures in some projects, the standardization may not be so high. At this time, it is necessary to check whether the supplier can put forward an effective and

In addition to the

Generally speaking, aluminum formwork is matched by digital technology, as a result, each aluminum formwork has a corresponding number. As long as the technical guidance is done well before assembly, the workers can successfully assemble the aluminum formwork. Therefore, the process of formwork assembly has low requirements for the workers’ experience. Moreover, we also need to note that aluminium formwork and self-climbing platform need to be used at the same time in some high-rise projects. If the aluminum formwork and self-climbing platform are used in the project at the same time, it may cause management problems, such as the conflict between the aluminum formwork and the self-climbing platform in the external wall and the problem of

When selecting

Reference

Ye, H. J., & Shi, M. J. (2007). Development Course and Prospect of Formwork. Shanxi Architecture, 33: 31.

Please feel free to contact us. Click on the page to know more about geto special engineering projects and integrated services of aluminium formwork and self-climbing platform.

Published: July 30, 2022

Last published: July 17, 2022

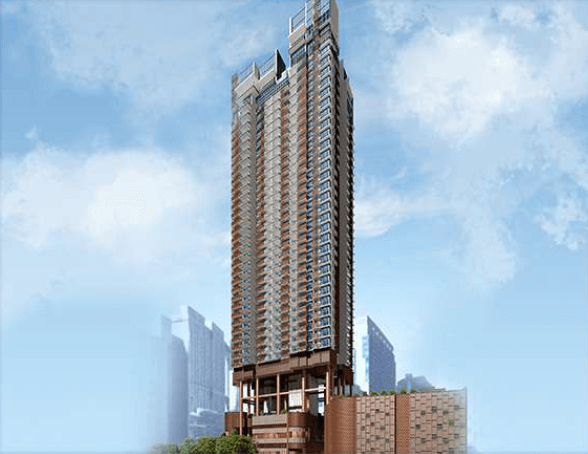

This project consists of 11 towers, formed by 2444 precast modules of 91 structural types. GETO supplied 35 sets of automated precast mould and 17 sets of non-automated precast mould for turnover in casting in this project.

GETO supplied 21 sets of automated precast mould for turnover in casting 38 precast modules in this tower.

Related article:

https://www.getoformwork.com/industry-news-articles/ppvc-housing-precast-formwork-system-geto/

https://www.getoformwork.com/enterprise-news-articles/geto-ppvc-housing-precast-formwork-system/

#PPVChousingprecastformworksystem

Published: July 17, 2022

Last published: June 30, 2022

GETO, an

One-time completion of business negotiation for

One-time understanding on similar lead time and integrated installation method of the aluminum formwork system and the self-climbing platform system.

Reduce the client’s travel time to the factory and the construction site for separate site inspection, and simplify the overlapping procedures of multiple-time approval, payment, and financial settlement that occur among the two product systems, increasing the

In combination with the main structure, the conflicts between the external walls of the

Modulate all-dimension design and detailing solutions that take care of both internal and external parties of the project in service, contributing to the prevention of on-site conflicts regarding the

Production and supply of the aluminium formwork system and the self-climbing platform system are conducted by one factory, with intensive production in place to reasonably match the expected time to produce orders. Materials of the aluminium formwork system and the self-climbing platform system for one project are delivered to the site at one time, and the factors of working progress and unloading sites are reasonably considered on the construction site in the overall delivery plan. Real-time tracking of the production progress of the

One-time completion of shell drawing designs, construction, and technical and safety briefing on the

All enquiries regarding the aluminium formwork system and the self-climbing platform system are managed by one particular person in charge, preventing possible miscommunication caused by multi-level management. For material management and

Centralized arrangement of goods return and recycling of the

Please feel free to contact us to get the service you want. Click on the page to know more about geto product and service.

Published: July 17, 2022

Last published: June 30, 2022

Related article:

https://www.getoformwork.com/industry-news-articles/ppvc-housing-precast-formwork-system-geto/

https://www.getoformwork.com/enterprise-news-articles/geto-ppvc-housing-precast-formwork-system/

#PPVChousingprecastformworksystem

Published: June 30, 2022

Last published: June 17, 2022

Upholding the business philosophy of customer-centric, GETO and its partner collaboratively committed into product development and upgrading works for the successful introduction of

GETO offers the following services:

Advantages:

Advantages:

Advantages:

GETO prefabricated mould system, compared with traditional construction technology, has unique four advantages:

Housing precast production formwork can form all struction of a building, including the deck, side wall, base floor, door opening, and window at one time, thus minimizing duration for the precast structure formation. Compared with the traditional steel formwork, it has over 50% enhancement in working site efficiency.

Ease site labour’s working intensity, while offers more assurance for construction workplace safety.

The green, low-carbon, and highly automated operating environment, in line with the trend of global low-carbon economy and the green building concept advocated by governments of various countries, is gradually replacing the conventional construction technology.

Related article: https://www.getoformwork.com/industry-news-articles/geto-ppvc-housing-precast-formwork-system-2/

#PPVChousingprecastformworksystem

Published: June 30, 2022

Last published: June 17, 2022

In recent years, the construction industry has been developing continuously. Under the background of “environmental protection is becoming stricter and labor shortage”, green, energy-saving, and efficient prefabricated buildings have been more and more widely used worldwide, receiving a new opportunity for development!

#PPVChousingprecastformworksystem

Published: June 17, 2022

Last published: May 31, 2022