As a leading provider of construction solutions, Geto Global Construction stands at the forefront of innovation in the industry. With a focus on efficiency and quality, we offer cutting-edge aluminium formwork building solutions tailored to meet the diverse needs of modern construction projects.

Streamlining Construction Processes with Aluminium Formwork Building

Aluminium formwork building has emerged as a game-changer in the construction sector, offering unparalleled efficiency and durability. At Geto Global Construction, we understand the importance of streamlining construction processes, and our aluminium formwork solutions are designed to do just that.

Maximizing Efficiency with Reusable Aluminium Formwork Systems

Our aluminium formwork systems are lightweight yet robust, ensuring ease of handling while maintaining structural integrity. By offering reusable formwork systems, we enable construction teams to optimize their resources and minimize waste, leading to significant cost savings and environmental benefits.

Ensuring Quality and Precision in Every Build

Precision is key in construction projects, and our aluminium formwork systems are engineered to deliver impeccable results with every pour. The rigid structure of our formwork ensures consistent alignment and dimensions, eliminating the need for extensive rework and adjustments, thus accelerating project timelines.

Delivering Unmatched Versatility for Diverse Construction Needs

One of the key advantages of Geto Global Construction’s aluminium formwork building solutions lies in their versatility. Our formwork systems can be customized to suit a wide range of construction requirements, from residential buildings to commercial complexes and infrastructure projects. Whether you’re constructing slabs, walls, columns, or beams, our aluminium formwork systems offer the flexibility and adaptability needed to tackle any construction challenge.

Conclusion: Elevating Construction Standards with Geto Global Construction

In conclusion, Geto Global Construction’s aluminium formwork building solutions represent a paradigm shift in the construction industry. By prioritizing efficiency, quality, and sustainability, we empower construction professionals to achieve their project goals with confidence and precision. With our comprehensive range of products and unwavering commitment to excellence, we are dedicated to elevating construction standards worldwide.

Incorporating the latest advancements in construction technology, our aluminium formwork systems enable faster assembly, smoother concrete pours, and enhanced structural integrity. Whether you’re embarking on a residential, commercial, or industrial project, our innovative solutions are designed to optimize efficiency and maximize value at every stage of the construction process.

Experience the difference with Geto Global Construction’s aluminium formwork building solutions. Contact us today to learn more about how our products can revolutionize your construction projects.

As a leading provider of construction solutions, Geto Global Construction is dedicated to optimizing building processes with our innovative formwork in Malaysia. In Malaysia, where construction projects are thriving, our formwork systems offer unparalleled efficiency and reliability.

Introduction: Revolutionizing Construction in Malaysia

At Geto Global Construction, we understand the importance of efficient and reliable construction processes in Malaysia’s growing market. With our advanced formwork solutions, we strive to streamline construction projects, saving time and resources while ensuring high-quality results.

The Benefits of Geto Global Construction Formwork in Malaysia

Our formwork solutions bring several advantages to construction projects in Malaysia:

1. Enhanced Efficiency: Our formwork systems are designed to accelerate construction timelines, allowing projects to be completed on schedule or even ahead of time. With efficient assembly and disassembly processes, construction teams can work seamlessly without delays.

2. Cost Savings: By reducing construction time and labor requirements, our formwork solutions help save costs for developers and contractors in Malaysia. Moreover, the durability and reusability of our formwork systems result in long-term cost savings for multiple projects.

3. Quality Assurance: Geto Global Construction formwork systems ensure consistent and precise concrete pouring, resulting in high-quality structures with minimal defects. This quality assurance is crucial for meeting regulatory standards and satisfying client expectations in Malaysia’s construction industry.

Why Choose Geto Global Construction for Formwork Solutions in Malaysia

When it comes to formwork solutions in Malaysia, Geto Global Construction stands out for several reasons:

1. Proven Track Record: With our extensive experience and successful projects worldwide, including in Malaysia, we have established a reputation for delivering reliable and high-performance formwork solutions.

2. Customized Solutions: We understand that every construction project in Malaysia is unique. Therefore, we offer customized formwork solutions tailored to the specific requirements and challenges of each project, ensuring optimal results.

3. Comprehensive Support: From initial consultation to on-site assistance and after-sales support, we provide comprehensive services to our clients in Malaysia. Our team of experts is dedicated to ensuring a smooth and successful construction process from start to finish.

Conclusion: Elevating Construction Standards with Geto Global Construction Formwork Solutions

In conclusion, Geto Global Construction is committed to revolutionizing the construction industry in Malaysia with our advanced formwork solutions. By enhancing efficiency, reducing costs, and ensuring quality, we empower construction projects across Malaysia to achieve their goals effectively and sustainably. Partner with us for your next construction project and experience the difference firsthand.

As a leading brand in the construction industry, Geto Global Construction is committed to providing innovative solutions that optimize efficiency and safety on the job site. One of our standout offerings is the self-climbing platform, a versatile tool that revolutionizes construction processes. In this article, we will delve into what self-climbing platforms are, their benefits, and why they are essential for modern construction projects.

What is a Self-Climbing Platform?

What is a Self-Climbing Platform? A self-climbing platform, also known as a self-raising formwork system, is a cutting-edge construction technology designed to streamline vertical construction processes. Unlike traditional scaffolding systems that require manual adjustment and dismantling, self-climbing platforms feature automated mechanisms that allow for continuous upward movement as construction progresses. This innovative system is typically used for high-rise buildings, bridges, and other structures where vertical construction is required.

The Benefits of Self-Climbing Platforms:

1. Enhanced Safety: Safety is paramount in the construction industry, and self-climbing platforms offer significant advantages in this regard. With automated climbing mechanisms and integrated safety features, such as guardrails and fall protection systems, these platforms minimize the risk of accidents and injuries on the job site.

2. Increased Efficiency: Traditional scaffolding systems require extensive manual labor for installation, adjustment, and dismantling. In contrast, self-climbing platforms streamline the construction process by automating vertical movement. This not only saves time but also reduces labor costs and accelerates project timelines.

3. Optimized Space Utilization: Self-climbing platforms are designed to maximize usable space on the job site. Their compact footprint and vertical mobility allow construction crews to work efficiently in tight spaces, such as urban environments where space is limited. This optimization of space leads to improved productivity and overall project efficiency.

Why Choose Geto Global Construction for Self-Climbing Platforms?

At Geto Global Construction, we prioritize quality, reliability, and innovation in all our products, including self-climbing platforms. Here’s why we stand out in the industry:

1. Advanced Technology: Our self-climbing platforms incorporate state-of-the-art technology to ensure smooth operation, precision positioning, and optimal safety features. We continuously invest in research and development to stay at the forefront of construction innovation.

2. Customization Options: We understand that every construction project is unique, which is why we offer customizable solutions to meet our clients’ specific requirements. Whether it’s adjusting platform dimensions, integrating additional safety features, or optimizing workflow processes, we tailor our solutions to fit your needs.

Conclusion:

In conclusion, self-climbing platforms are a game-changer in the construction industry, offering unparalleled safety, efficiency, and space optimization benefits. As a trusted provider of construction solutions, Geto Global Construction is proud to offer innovative self-climbing platforms that enhance project outcomes and exceed client expectations. Contact us today to learn more about how our self-climbing platforms can elevate your construction projects to new heights.

In the realm of modern construction, efficiency, durability, and sustainability are paramount. At Geto Global Construction, we understand these demands implicitly, and our cutting-edge solutions are designed to meet and exceed them. One such solution revolutionizing the industry is the integration of aluminum in construction projects. From skyscrapers to residential complexes, the versatility and reliability of aluminum are reshaping the way we build for the better.

Aluminium in Construction: A Game-Changer

Aluminium has emerged as a game-changer in the construction industry for several compelling reasons. Its lightweight yet robust nature makes it an ideal choice for a myriad of applications, offering unparalleled strength without the added bulk. At Geto Global Construction, we leverage the power of aluminum in our innovative formwork systems, scaffolding solutions, and precast components to streamline construction processes and elevate project outcomes.

Enhancing Efficiency with Aluminium Formwork Systems

Our aluminum formwork systems stand as a testament to the transformative power of modern construction techniques. By replacing traditional materials like wood and steel with lightweight aluminum, we’ve optimized the construction process from start to finish. The simplicity of installation, coupled with the reusability of our formwork systems, ensures significant time and cost savings without compromising on quality.

Elevating Safety and Durability with Aluminium Scaffolding

Safety is non-negotiable in any construction project, which is why our aluminum scaffolding solutions are engineered with precision and reliability in mind. The inherent strength of aluminum, combined with intelligent design features, provides a secure platform for workers at any height. Moreover, aluminum’s resistance to corrosion and weathering ensures long-term durability, offering peace of mind in even the most challenging environments.

Maximizing Sustainability with Aluminium Precast Components

Sustainability is a core tenet of our philosophy at Geto Global Construction, and aluminum plays a pivotal role in our commitment to eco-friendly practices. Our precast components harness the inherent recyclability of aluminum, minimizing waste and reducing environmental impact. By optimizing material usage and maximizing efficiency, we’re paving the way towards a greener, more sustainable future for the construction industry.

Conclusion: Redefining Construction with Aluminium

In conclusion, the integration of aluminum in construction represents a paradigm shift towards efficiency, durability, and sustainability. At Geto Global Construction, we’re proud to lead the charge in harnessing the full potential of aluminum to revolutionize the way we build. From formwork systems to scaffolding solutions, our innovative products are setting new standards for quality and performance in the construction industry. Join us as we continue to push the boundaries of possibility and unlock new horizons in modern construction.

铝模板系统现已广泛应用于建筑领域,为住宅建筑和公共建筑项目提供轻质优质模板。工业厂房建筑是铝模板系统的典型应用之一。

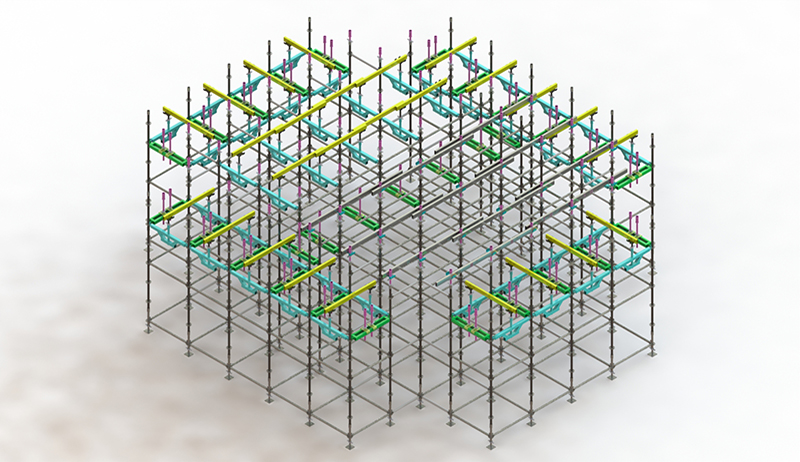

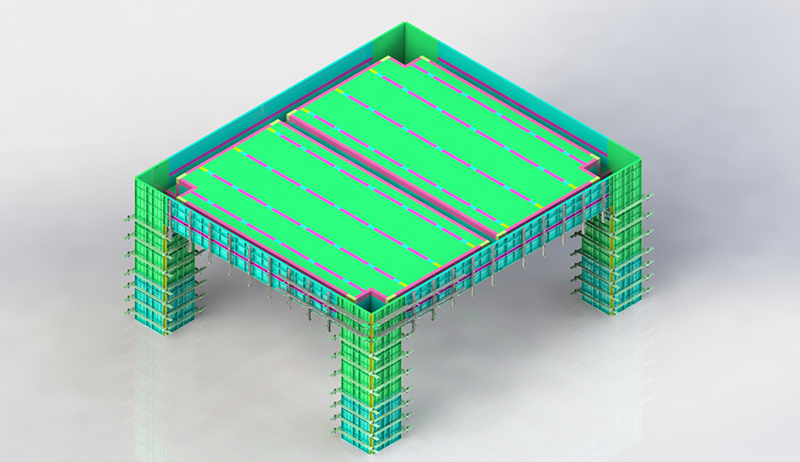

我们专门为工业建筑项目研发推出了GT-48轻型早拆工业模板体系。该体系采用支撑梁板共支支撑设计,与早拆铝合金模板体系进行融合,释放了支撑间距,拓展了铝合金模板使用范围。该套体系具有可早拆、标准化程度高、可重复使用、可快速周转、成型质量优、绿色环保等综合优势。

此模板体系为轻型结构,适用于现浇框架结构地下室、架空层、工业厂房、冷链仓储物流园等工业建筑。可根据不同的结构形式,选择不同的模板组合方案。

| 支撑系统 | |

| 48标准盘扣脚手架构件 | 由可调底座、调节螺母、标准基座、立杆、横杆、斜杆、可调托座组成 |

| 新制构件 | 由托梁横杆、加强横杆、可调套管顶托组件、50*100矩形管组成 |

| 模板系统 | |

| 墙模系统 | 由标准铝模体系及加固背楞组成,采用标准铝模支模工艺 |

| 柱模系统 | 由标准铝模体系、方圆扣加固组件、48钢管、直角扣件组成、平板过渡转接件、50*50木方、t15木胶合板组成 |

| 梁楼盖模板系统 | 由标准铝模体系、平板过渡转接件、50*50木方、t15木胶合板组成 |

志特是一家领先的模板公司,在制造创新建筑材料方面拥有多年的经验。我们拥有丰富的建筑项目成功经验,并享有较高的知名度。我们的铝模板系统拥有卓越的性能和耐用性等技术品质。其中,我们的 GT-48 轻型早拆工业模板系统具有以下优势:

• 应用范围广:适用于6m以上层高框架结构建筑,可实现模板早拆,解决了铝合金早拆模板体系适用范围受限问题。

• 高承载能力:刚度设计理念,模板体系充分利用盘扣支撑的高承载能力,通过转接件加强模板刚度,适用于大荷载梁及顶板结构。

• 体系规范化:工业模板体系同时符合盘扣脚手架、铝合金模板两种产品规范。

• 产品标准化:采用全标准化模板,铝模的覆盖使用率达到95%以上。

• 设计人性化:通过使用不同颜色的模板,方便现场的模板管理,提高工作效率。

• 拼装工具化:工具式拼装,现场裁剪率减少95%以上,对工人水平要求低,有明确的拼装教程和拼装验收规范,保证了拼装质量。

• 成型质量好:工厂加工工具化模板,加工精度高,模板拼缝整齐,成型效果好。6m以上层高建筑成型质量高于垂8平8,优于传统木模成型质量。

• 文明施工程度高:配备施工操作平台,使施工现场安全且干净整洁,建筑垃圾少,可以节省材料清理、安全防护等文明施工费用。

• 综合成本低:可预留出后期装修水电所需的企口水管、压槽等特殊构造,节省后期的人工打凿、垃圾清理、修补打磨等费用。

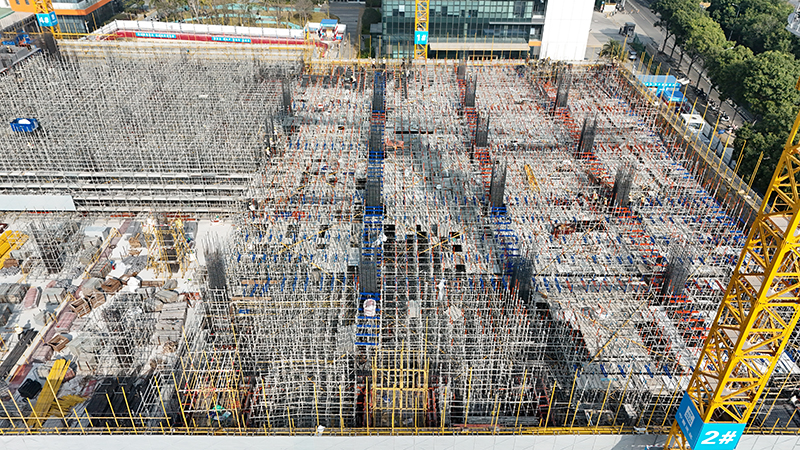

深福保科技生态园提容项目计划于2025年9月竣工交付使用。该项目规划建成电子元器件产融物流中心,以实现集仓储、分拨、集拼等多种功能于一体的复合空间载体。

该项目总建筑面积约12万平方米,由东和西两个地块组成,总建筑面积近50万平方米,前两层层高达到10.5米,属于超高大支模,且层高变化大,从10.5米变化至6米,后变化至4.5米,柱子尺寸大,加固困难,现场场地有限,工期时间紧迫,针对该项目特点我们建议采用铝模+盘扣支撑架体或铝模+独立支撑的早拆建筑方案。

这是国内首个大面积高支模盘扣铝模一体化早拆工业模板体系施工项目。在该项目中,GT-48 轻型早拆工业模板系统扩展了铝模应用范围,提高了高支模施工成型质量。同时,它减少了建筑垃圾,使模板可以早拆可周转使用,从而降低了模板使用成本,为项目施工降本增效。

作为工业厂房建设的可靠解决方案,GT-48轻型早拆工业模板系统具有标准化、人性化、经济效益高的关键优势。此外,我们还提供物资供应、现场施工、现场管理一体化服务模式,让客户享受到便捷和高效的服务体验。欢迎联系我们,了解我们的方案如何优化您的项目。

欢迎浏览我们的网站,了解更多关于我们的建筑解决方案和综合服务的信息。

At Geto Global Construction, we pride ourselves on our innovative solutions, and one of our standout offerings is our Automatic Climbing System. So, you might be wondering, whatisAutomatic Climbing System, and how does it benefit construction projects? Let’s delve into the details.

Understanding Automatic Climbing System

The Automatic Climbing System is a cutting-edge technology designed to streamline the construction process, particularly for high-rise buildings. It consists of a series of hydraulic jacks and platforms that are attached to the building structure, allowing for vertical movement as construction progresses upward.

How Does It Work?

Our Automatic Climbing System operates on the principle of vertical ascent. Once installed, it facilitates the controlled movement of formwork, enabling seamless pouring of concrete and advancement of the construction cycle. The system is meticulously engineered to ensure stability, safety, and efficiency throughout the construction process.

Key Benefits of Automatic Climbing System

1. Enhanced Efficiency

By automating the climbing process, our system significantly accelerates construction timelines. With smoother and faster vertical movement, projects can be completed within shorter timeframes, optimizing resource utilization and reducing overall costs.

2. Improved Safety

Safety is paramount in any construction project, and our Automatic Climbing System prioritizes it. With automated mechanisms and stringent safety features, the risk of accidents and injuries is minimized, providing peace of mind to project stakeholders.

3. Streamlined Workflow

The integration of the Automatic Climbing System into construction workflows enhances overall project management. With precise control over vertical movements, project managers can efficiently coordinate tasks, ensuring seamless progress and timely completion.

Embracing the Future of Construction

As we look to the future, Geto Global Construction remains steadfast in our commitment to innovation and excellence. With our Automatic Climbing System leading the charge, we’re poised to shape the skyline of tomorrow, one towering achievement at a time.

Maximizing the Potential of Your Projects

Beyond its immediate benefits, the Automatic Climbing System from Geto Global Construction opens doors to a plethora of opportunities for your construction endeavors. Its adaptability and versatility make it suitable for a wide range of high-rise projects, from residential towers to commercial complexes and beyond.

Conclusion

In conclusion, the Automatic Climbing System offered by Geto Global Construction represents a paradigm shift in high-rise construction methodologies. With its efficiency, safety, and workflow optimization features, it’s not just a tool but a catalyst for success in modern construction projects. Reach out to us today to discover how our Automatic Climbing System can elevate your next project to new heights.

At Geto Global Construction, we pride ourselves on offering innovative solutions tailored to the evolving needs of the construction industry. Today, we delve into the topic of climbing scaffolds, shedding light on what they are, how they work, and their benefits.

Understanding Climbing Scaffolds

What is a climbing scaffold? Climbing scaffolds, also known as self-climbing platforms, are advanced systems designed to facilitate construction processes, especially in high-rise projects. Unlike traditional scaffolding methods, climbing scaffolds are mechanized, offering enhanced efficiency and safety.

How Climbing Scaffolds Work

These scaffolds operate on a hydraulic or motorized system that enables vertical movement along the building’s facade. As the structure rises, the scaffold “climbs” with it, providing continuous access to different levels of the construction site. This automation minimizes the need for manual adjustments, streamlining the construction process.

Key Benefits of Climbing Scaffolds

1. Enhanced Safety: Climbing scaffolds reduce the risks associated with traditional scaffolding, such as falls and accidents. The mechanized system ensures stable support, even at great heights, enhancing worker safety.

2. Improved Efficiency: By eliminating the need for manual dismantling and reassembly, climbing scaffolds optimize construction timelines. Workers can focus on their tasks without interruptions, leading to faster project completion.

3. Cost-Effectiveness: While climbing scaffolds may require a higher initial investment, their efficiency translates to cost savings in the long run. Reduced labor costs and accelerated construction schedules contribute to overall project affordability.

Geto Global Construction: Your Partner in Innovative Solutions

As a leading provider of construction materials and solutions, Geto Global Construction is committed to excellence in every project we undertake. With our expertise in climbing scaffolds and other cutting-edge technologies, we empower construction teams to achieve their goals efficiently and safely.

Conclusion

In conclusion, climbing scaffolds represent a significant advancement in construction methodology, offering enhanced safety, efficiency, and cost-effectiveness. As the industry continues to evolve, Geto Global Construction remains at the forefront, delivering innovative solutions that drive progress and success.

For more information about climbing scaffolds and our comprehensive range of construction solutions, contact us today. Together, let’s build a better future.

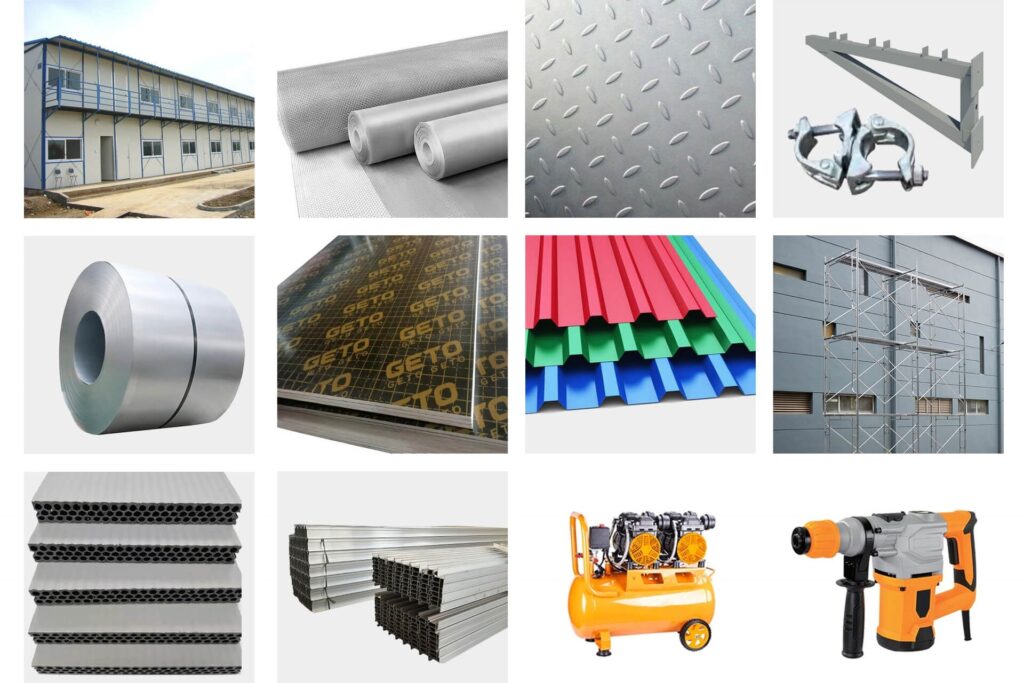

The eagerly awaited 135th Canton Fair 2024 Spring is approaching, scheduled to be held from April 23rd to April 27th at the Guangzhou Canton Fair. As a global construction company, we are excited to announce our participation as an exhibitor and invite you to visit our booth. Geto will exhibit our aluminium formwork products, building construction products, and decoration materials.

Date: April 23rd to April 27th

Venue: China Import and Export Fair Complex

Area: B Area

Hall: 13.1 Hall

Booth: D09-10

You can Get High-Quality Building Construction at 2024 Canton Fair

As a global construction company, we are dedicated to transforming the construction industry through our innovative and high-quality products. At the Guangzhou Canton Fair 2024, we are proud to showcase our latest innovations tailored to enhance safety, efficiency, and sustainability in construction projects worldwide. Let’s explore the building services that we offer.

The Geto aluminium formwork system is ideal for constructing both civil buildings and part of the structures of public construction. Our aluminium formwork construction guarantees high-quality aluminum formwork with precise measurements and a significant load-bearing capacity. This not only reduces construction costs but also speeds up construction progress and enhances safety. It is also one of the essential products we will display to our customers at this Canton Fair 2024.

Our protection screen is an innovative safety device attached to structures (floors, beams, or walls) and lifted using a tower crane or hydraulic system. The GETO building product is specifically designed to fulfill peripheral protection needs for high-rise and super-high-rise buildings. GETO protection screen can withstand a maximum wind load of 9 levels without extra reinforcement. Its components have strong universality for easy management, making them an indispensable safety protection measure for building construction.

Building Materials for Structural Construction

Our construction materials are designed to meet stringent structural standards and include various products such as aluminium sheets, aluminium coils, aluminium beam formwork, and formwork support frames. Welcome to the Canton Fair 2024 exhibition hall to have an in-depth discussion with us about the building materials you need.

Automated Production and High Efficiency for Precast Concrete Structure. It reduces labor-intensive work and improves safety at the construction site.

Our quick-deck formwork is easy and compatible with other formwork systems and fast construction for beamless and large-area deck structures. Its fast assembly and disassembly are facilitated by adjusting the height of the adjustable props under the deck formwork, which are raised for tightening and installation.

This innovative framework is specifically designed for wall construction, catering to buildings with strict waterproofing requirements, such as the railway station and the external wall of the basement.

Our table formwork ensures fast overall installation, exceptional work efficiency and a high material reusability rate. It is suitable for beamless floor structures with large bays, large depths, and no column caps.

Our lifting shaft platform system is an easy and fast overall installation for shaft projects. It can be lifted layer by layer with a tower crane in place. The entire system can be reset by contracting and expanding, providing a holistic and mechanized approach to lift shaft construction.

GT-48 Lightweight Industrial Formwork System

GT-48 lightweight industrial formwork system adopts the design of common support for beams and slabs and integrates with the aluminium formwork system, expanding the scope of aluminium formwork applications. The system has comprehensive advantages such as a high degree of standardization, reusability, quick turnover, excellent forming quality, and environmental friendliness.

If you are still interested or have questions about GETO products, we will be happy to answer them face-to-face at the 2024 Guangzhou Canton Fair. We will demonstrate our position as a global construction company and showcase our products through videos, brochures, and product displays. This is a great opportunity for you to explore our innovative solutions closely. At the 2024 Canton Fair, you can consult with our professional team on building construction-related matters, and we will provide you with professional answers.

Sincerely Invite You to Attend the Canton Fair

At the Canton Fair 2024, you can get a closer look at our achievements in construction. Feel free to tell us what you need at the canton fair, and we will provide you with solutions. Suppose you want to know about new green, new-type building aluminum formwork, self-climbing platforms, assembly PC components, and other construction products. In that case, GETO will provide you with more information at the exhibition. We have also developed PPVC precast housing molds, quick-deck systems, single-side wall frameworks, table formwork, shaft platforms, and other building materials for structural construction. Our business operations extend to civil and public construction sectors in Malaysia and Singapore, among others.

As the Canton Fair Spring 2024 approaches, we cordially invite you to visit our booth at D09-10, Hall 13.1, Area B. See firsthand how our global construction company is shaping the industry and enhancing construction projects worldwide. We are excited to meet you there!

As a leading player in the construction industry, we at Geto Global Construction are committed to providing innovative solutions that enhance efficiency and quality in building projects worldwide. One of the key components in modern construction that we specialize in is formwork. But what does formwork mean in construction, and how does it contribute to the success of a project? Let’s delve deeper into this essential aspect of construction methodology.

Understanding Formwork in Construction

Formwork in construction refers to the temporary molds or structures used to support and shape concrete until it sets and becomes self-supporting. It plays a crucial role in ensuring that concrete structures are formed accurately and efficiently. Essentially, formwork acts as the framework that holds the concrete in place during the pouring and curing process.

The Importance of Formwork

Formwork is indispensable in construction projects for several reasons:

1. Precision and Accuracy: Properly designed and installed formwork ensures that concrete structures are formed with precision and accuracy, meeting architectural and engineering specifications.

2. Efficiency: By providing a stable and uniform framework, formwork facilitates the efficient pouring and shaping of concrete, reducing construction time and labor costs.

3. Safety: Well-designed formwork systems enhance safety on construction sites by providing stable platforms for workers and minimizing the risk of accidents during concrete placement.

Our Contribution to Formwork Solutions

At Geto Global Construction, we recognize the critical role that formwork plays in construction projects. That’s why we offer a comprehensive range of innovative formwork solutions designed to optimize efficiency and quality:

1. Aluminum Formwork Systems: Our aluminum formwork systems are lightweight, durable, and easy to assemble, making them ideal for a wide range of construction applications. With precise engineering and high-quality materials, our formwork systems ensure superior results with every pour.

2. Self-Climbing Platforms: Our self-climbing platforms provide safe and efficient access for workers during the construction process. Designed for high-rise projects, these platforms offer enhanced productivity and safety, allowing for seamless vertical progression.

3. PC Precast Systems: Prefabricated PC (precast concrete) components offer a streamlined solution for construction projects, reducing on-site labor and time requirements. Our PC systems are customizable and manufactured to the highest standards, ensuring consistent quality and performance.

Conclusion: Elevating Construction Standards with Formwork Solutions

In conclusion, formwork is a fundamental component of modern construction methodology, shaping the way we build structures today. At Geto Global Construction, we are proud to be at the forefront of revolutionizing formwork solutions, offering innovative systems that enhance efficiency, precision, and safety on construction sites worldwide. With our comprehensive range of formwork products and unwavering commitment to quality, we continue to drive positive change in the construction industry, one project at a time.

At Geto Global Construction, we pride ourselves on providing innovative solutions that optimize construction processes and enhance project efficiency. One such solution gaining traction in the industry is self-climbing formwork. But whatis self-climbing formwork, and how does it contribute to streamlined construction workflows? Let’s delve into this technology and explore its benefits.

Understanding Self-Climbing Formwork

Self-climbing formwork is a cutting-edge construction technique that simplifies the process of building vertical structures such as high-rise buildings, bridges, and towers. Unlike traditional formwork systems that require manual adjustment and repositioning, self-climbing formwork operates autonomously, gradually moving upward as the structure rises.

How Does It Work?

Self-climbing formwork consists of a series of formwork panels mounted on a hydraulic or mechanical climbing system. As the concrete is poured and cured at lower levels, the climbing system incrementally raises the formwork to the next level, allowing construction to progress seamlessly without the need for manual intervention. This continuous upward movement eliminates the downtime associated with dismantling and reassembling formwork, significantly accelerating the construction timeline.

The Advantages of Self-Climbing Formwork

1. Enhanced Efficiency: By automating the climbing process, self-climbing formwork reduces labor requirements and speeds up construction, enabling projects to be completed ahead of schedule.

2. Improved Safety: With fewer manual operations at height, the risk of accidents and injuries is minimized, creating a safer working environment for construction workers.

3. Optimized Resource Utilization: Self-climbing formwork maximizes the use of materials and equipment, resulting in cost savings and reduced waste generation.

4. Versatility: This technology can be customized to suit various project requirements, making it suitable for a wide range of construction applications.

Our Commitment to Excellence

At Geto Global Construction, we are dedicated to delivering high-quality construction solutions that meet the evolving needs of our clients. With our expertise in self-climbing formwork and other innovative technologies, we empower construction projects to achieve new levels of efficiency and productivity.

The Future of Construction with Self-Climbing Formwork

As the construction industry continues to evolve, the demand for efficient and sustainable building techniques grows stronger. Self-climbing formwork represents a significant step forward in this regard, offering a glimpse into the future of construction.

Conclusion

In conclusion, self-climbing formwork revolutionizes the way vertical structures are built, offering unparalleled efficiency, safety, and versatility. As a leading provider of construction solutions, Geto Global Construction is proud to spearhead the adoption of this transformative technology in the industry.