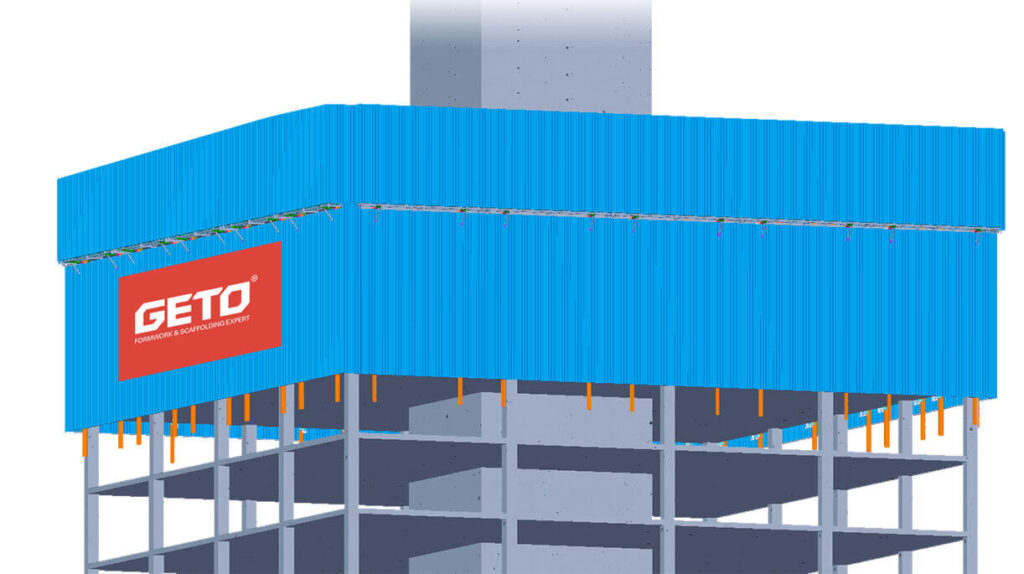

Protection screen is an innovative safety device attached to structures (floors, beams, or walls) and lifted using a tower crane or hydraulic system. Specifically designed to fulfill peripheral protection needs for high-rise and super-high-rise buildings.

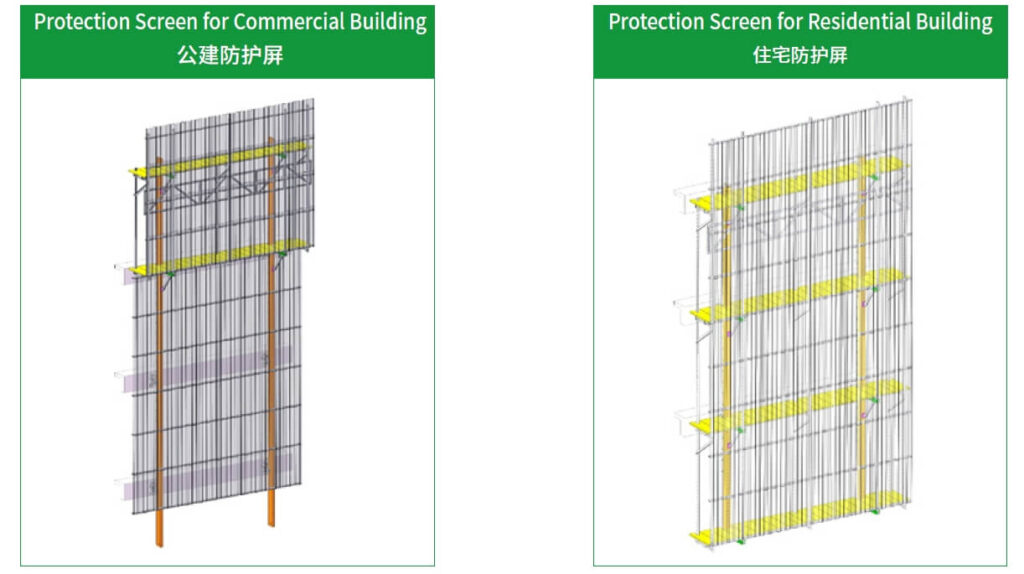

There are obvious differences between the facade walls of commercial and residential buildings. Residential buildings typically have many facades, demanding protection screens for exterior work, while commercial buildings’ fewer facades permit work from internal edges.

Therefore, GETO protection screens are categorized into residential protection screens with more platform layers, and commercial building protection screens with fewer platform layers.

① Guide rails and platform boards are 0.3m from the wall for easy installation of beam and wall formwork.

② Seal flaps can be installed as needed.

High wind resistance

▪ Capable of withstanding a maximum wind load of 9 levels without extra reinforcement. Additional reinforcement is needed for wind loads beyond level 9.

Fall arrest

▪ Fall arrest devices attached during climbing are independent, minimizing safety issues resulting from operational errors.

▪ Protection against personnel and items being dropped is ensured by full sealing, including guide rails, corners, and protruding parts.

▪ All components undergo rigorous testing, including extreme loads and falls, to ensure safety in extreme conditions.

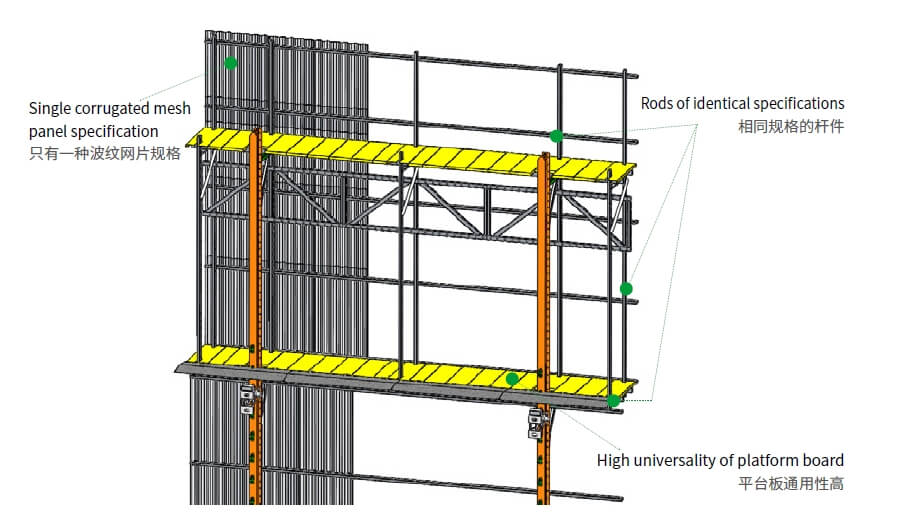

▪ Strong universality of components for easy management.

Main components do not exceed 10 types, achieving a universal compatibility rate of 95% or higher.

▪ Hydraulic drive system.

Compared to conventional protection platform using electric hoists and electronically controlled, the cost is lower.

▪ Reliable, maintainable, and easy to operate.

▪ Lower costs for disassembly, transportation, and labor due to the lightweight frame compared to regular steel climbing platforms.

▪ Suitable for diverse shapes and heights of structure. Adjustable floor supports permit use on facades with both varying and constant inclinations.

▪ Platform boards and sealed flaps can align with floor levels.

| S/N | Item | Unit | Specification | Remark |

| 1 | Framework height | m | 8~13.5 | Adapting framework height to project conditions |

| 2 | Framework width | m | 0.6-1.2 | Standard platform board width: 0.88m |

| 3 | Machine position affecting width | m | 3.5 | Total length varies with machine position count |

| 4 | Single unit weight | T | 1.3 | Calculating based on a 2.5-level protection screen, with a machine position affecting width of 3.5m |

| 5 | Rated lifting capacity of the power unit | T | 3.5 | Hydraulic cylinders, pump station |

| 6 | Power unit capacity | KW | 1.5 | Voltage: 380V/415V, Frequency: 50Hz, Max fuse current: 5A (Motor can be customized based on local electrical specifications) |

| 7 | Single lift height of hydraulic cylinder | m | 0.3 | Effective lift height: 0.3mTotal cylinder stroke: 0.42m |

| 8 | Lifting speed | m/min | 0.3 | |

| 9 | Time for lifting one level | min | 10 | Calculating based on a 3m floor height |

| 10 | Platform load capacity | kN/㎡ | 2 | Operating on a two-level platform (200kg/m² load capacity per level) |

In the year of 2023, GETO, the “1+N” one-stop solution provider, has worked with international clients to create a series of excellent construction projects. We selected 7 of the most representative projects, let us take you to enjoy the charm of green and smart buildings.

As China proposed the joint construction of the “One Belt One Road” initiative, which laid the foundation for good business cooperation between the two countries, GETO actively assisted in the construction of local affordable housing and infrastructure.

Project Highlight:

▪ The project is about 130 apartments and affordable houses.

▪ PC and traditional wood formwork and other processes are still the main construction methods in the local market, and local customers and labor workers are not familiar with aluminium formwork. GETO provides engineering guidance services for supporting products to help laborers use the products smoothly and improve the local market’s recognition of aluminium formwork.

▪ GETO provides customized design solutions to suit the characteristics of local houses, such as low-rise villas with thick walls.

This project is one of the longest main spans of its type in Southeast Asia. Once completed, the project will connect to the coastal highway, effectively improving local transportation and driving surrounding economic development.

Project Highlight:

▪ The total length of the bridge is about 4693m, the bridge length is 2390 meters (of which the main bridge is 1110 meters long), and the bridge deck is 12.4m wide. The bridge structure has the characteristics of ultra-long pile foundation in water, large pile cap, high piers, and extra-large span.

▪ GETO is glad to provide the cofferdam, pier, and bent cap etc to ensure project quality with many unfavourable factors such as urgent construction schedules, complex construction environment, etc. GETO overcame them all and provided our on-site engineering guidance to ensure the smooth use of products.

The project is located in New City Zone A — Area A3,Macao. It is an important livelihood project. Covering an area of 11,668 square meters, it mainly includes approximately 754 residential units, public parking lots, and commercial and social facilities. The project uses prefabricated concrete and metal formwork for construction of green construction.

Project Highlight:

▪ In the GETO production base, We provide pre-assembly service of aluminium formwork with PC components.

▪ GETO aluminium formwork is flexible and can be combined with many systems such as timber formwork/ PC components to achieve good pouring effect, and the optimal solution with the lowest comprehensive cost.

The project has two buildings, they are 148 meters high and 122 meters high respectively, providing 0.24 million square meters of office space. The project is strategically located atop a high-speed rail station and close to several major transportation lines. It has marvellous transportation advantages and connects major cities on the mainland to other parts of the world.

Project Highlight:

▪ It is an exclusive-customized solution provided by GETO. Its structure is a big project that is composed of aluminium formwork of 30,000 square meters of construction area at once.

▪ Among them, arc and cylindrical panels account for 5%; customized non-standard parts for 10%; and 13+ aluminium formwork structural change layers are included.

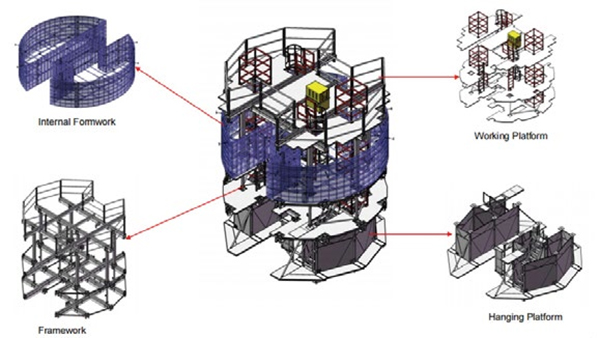

The project contains a 50 km tunnel across the southern and western regions of Singapore. It is an important part of the local drainage integration system. GETO provided the shaft formwork system for this project help to solve the drainage problem.

Project Highlight:

▪ This product has many advantages such as fast construction speed, high safety, high degree of mechanization, and labor saving.

▪ Each jacking operation only takes 2 to 3 hours.

▪ The steel platform of the top formwork system has large overall rigidity and large bearing capacity. The platform bearing capacity reaches 10 kN/㎡.

▪ The measurement control points can be directly projected onto the steel platform for construction measurement convenience.

GETO comprehensively considers factors such as construction convenience, comprehensive cost, and high product turnover rate to develop a tunnel formwork system for customers. It is also the fastest and most economical way to build high-quality earthquake-resistant apartments, villas, student dormitories, and hotels. Currently, GETO provides tunnel molds made of steel and aluminium for customers to choose from. Steel tunnel formwork is used in this project.

Product Highlight:

▪ Simple formwork process, low labor force;

▪ Tightly spliced, not easy to deform;

▪ Good integrity of formwork, strong seismic resistance;

▪ Good insulation performance, conducive to winter concrete insulation;

▪ Large formwork dismantling, high level of mechanization, good safety performance.

Savana is a majestic 36-storey serviced apartment that stands as part of the iconic Utropolis at Batu Kawan. It will offer 522 units of condominium after finishing.

Project Highlight:

▪ The self-climbing platform is 9 meters high, equivalent to 2.5 standard floors, large scale.

▪ The project is located close to nearby residential buildings, making construction difficult and requiring high self-climbing platform installation requirements.

▪ Customized solutions, covering the residential building part of the project as required, saving costs for client.

Aluminum formwork systems have seen broad use in construction due to their benefits over traditional timber and steel formwork. An aluminum system gives builders a functional solution, delivering precision, speed, safety, and sustainability on projects big and small. It enables fast, efficient building of walls, columns, and slabs through lightweight yet sturdy aluminum panels. This pioneering aluminium formwork system technology has massively boosted construction productivity globally.

There are two primary aluminium formwork system types used in building construction. Each caters to different project requirements by fulfilling the structural and functional needs of a wide variety of construction projects. The types include:

This formwork system features internal connectors and flat ties to fix formwork panels together. It requires less accessories for assembly and provides higher precision. Without tie-rod holes, it achieves a smoother concrete surface finish.

With external connectors and tie rods passing through the panels, the tie-rod aluminium formwork system delivers high strength and stability essential for renovation projects or structures with a wall thickness of over 400mm. Its versatility enables formwork refurbishment and repeated usage on multiple floors of high-rise buildings.

Panels, connectors, and bracing elements are the core component categories of an aluminium formwork system. These components work together to enable smooth construction.

Panels act as the main load-bearing parts and come in various types to serve different purposes. Wall panels are the most commonly used and contain tie rod holes for the construction of walls. Wall top panels are utilized for the tops of walls. Column panels form the molds for column construction. Crane-way panels provide paths for cranes to travel on during high-rise building works.

Connectors play a vital joining role. External joint connectors fix panels on the outside of structures. Internal joint connectors are used between adjacent panels from inside. Beam corner joints connect wall and beam panels at angled positions. The sturdy designs of these connectors guarantee panels are firmly interlocked and free of gaps or misalignment.

Temporary bracing elements provide crucial stability to support beams, roofs, and more during construction. Kicker braces support the base of beams. Soffit braces are attached to slab undersides. Semi-circular rocker braces resist uneven loading on curved structures. The adjustable bracing connections conform to irregular profiles and deliver maximum safety even under high load conditions.

The premier formwork company GETO has years of experience designing and manufacturing world-class aluminium formwork system solutions. We are committed to innovation and sustainability, with 10 production bases and large annual capacity. Our one-stop solutions include formwork, scaffolding, precast components, and more. Developing new products and solutions to maximize construction efficiency is the key strength that sets us apart from the competition.

At GETO, we provide comprehensive aluminium formwork system solutions and whole-chain services, including system design, formwork material provision, scaffolding solutions, equipment leasing, technical training, and maintenance support. Customers benefit from our:

Overall, aluminium formwork systems have evolved the construction process. The two primary types of aluminium formwork – flat-tie and tie-rod systems are suitable for different project requirements and constraints. Major components of aluminium formwork systems, such as panels, connectors, and bracing elements, all enable smooth construction.

As a leading global brand, GETO offers project-specific solutions through a wide choice of high-quality aluminium formwork and one-stop services. Our customers are assured of maximum efficiency and safety, as well as savings on their construction in Malaysia, Singapore, etc. Visit our website to learn more about our innovative offerings.

Formwork systems play a pivotal role in the construction industry as they are used to mold cast-in-place concrete into desired shapes. There are different types of systems available depending on the material used – the two primary ones being timber formwork and aluminum formwork systems. Both these types are lightweight compared to traditional steel formwork, which makes them easy to transport and install on construction sites. However, their properties are quite different, making one suitable over the other for specific applications or project requirements.

Before choosing between aluminum and timber formwork, it is important to do a comparative analysis of both so you can understand their unique features and suitability for different construction needs. The following aspects highlight their difference:

1. Weight

Both aluminum and timber formwork systems are lightweight. However, aluminum formwork can be slightly heavier. Still, they are easy to handle and transport compared to steel formworks.

2. Durability

Aluminum formwork systems are much more durable than timber ones. Timber formwork is susceptible to termites, rot, and other deterioration over time due to exposure to weather elements. Aluminum formwork, on the other hand, can withstand challenging site conditions and last longer with proper maintenance.

3. Efficiency

The assembly and dismantling of aluminum formwork are faster than timber formwork due to its interlocking panel system. This enhances productivity and efficiency on construction sites. Timber formwork requires more labor and time for assembly and stripping work.

4. Cost-Effectiveness

For small to medium-scale projects, timber formwork is generally a cheaper option than aluminum. However, for large projects involving repetitive concrete work, an aluminum formwork system proves to be more cost-effective. This is because the initial high cost of aluminum formwork is compensated by its reusability and efficiency.

5. Flexibility

Both materials allow for flexibility in design. Timber formwork can be customized according to specific project requirements by cutting them on-site. Aluminum formwork comes in standard sizes but can still be adapted across different projects with proper modifications and renovation.

6. Concrete Surface

Aluminum formwork provides a very smooth concrete surface due to its non-absorbent panels. Timber may leave intricate grain textures or irregularities on concrete.

7. Reusability

Aluminum formwork can be reused multiple times with proper repairs and maintenance. Timber formwork, on the other hand, has low reusability because of its short lifespan and deterioration over time.

For small projects with short durations, both timber and aluminum formwork systems prove to be suitable choices. Timber formwork is cost-effective due to its relatively lower initial investment, while aluminum formwork also offers cost savings since it can be bought back or recycled.

For projects that span over longer construction timelines, such as complex commercial buildings, hospitals, or highways, aluminum formwork out-beats timber. It offers the durability required over an extended period. Similarly, multi-tower residential or mixed-use developments harness the reusability of aluminum formwork to pour repetitive structural elements efficiently. Because of their longevity even in changing site conditions, aluminum formwork systems are particularly suitable for projects that involve phases carried out over multiple seasons.

GETO is a leading and experienced formwork company that specializes in providing aluminum formwork solutions. Headquartered in Guangdong, China, we have 12 domestic and international production bases with an impressive combined annual manufacturing capacity. We offer a wide range of formwork systems, climbing platforms, and precast concrete components. At GETO, our team is committed to quality, customer service, environmental protection, and social responsibility. Our advantages include:

Our aluminum formwork systems can be used to construct common structural elements like floors and basements of residential buildings. Some examples are high-rise apartment complexes, office towers, and hotels. Our formwork solutions are also suitable for portions of public infrastructure like bridges, tunnels, underground utilities, and railroads. The durable and reusable systems facilitate the rapid construction of repetitive concrete sections across different project types.

Both aluminum and timber formwork have their respective qualities. For large and complex construction projects, aluminum formwork proves more practical and efficient compared to timber, thanks to its above-mentioned unique advantages. At GETO, we offer high-quality aluminum formwork solutions customized for various structural requirements. With years of experience, robust in-house R&D, and strict quality standards, we have become a trusted name in the industry. Visit our website to explore our dependable building formwork solutions.

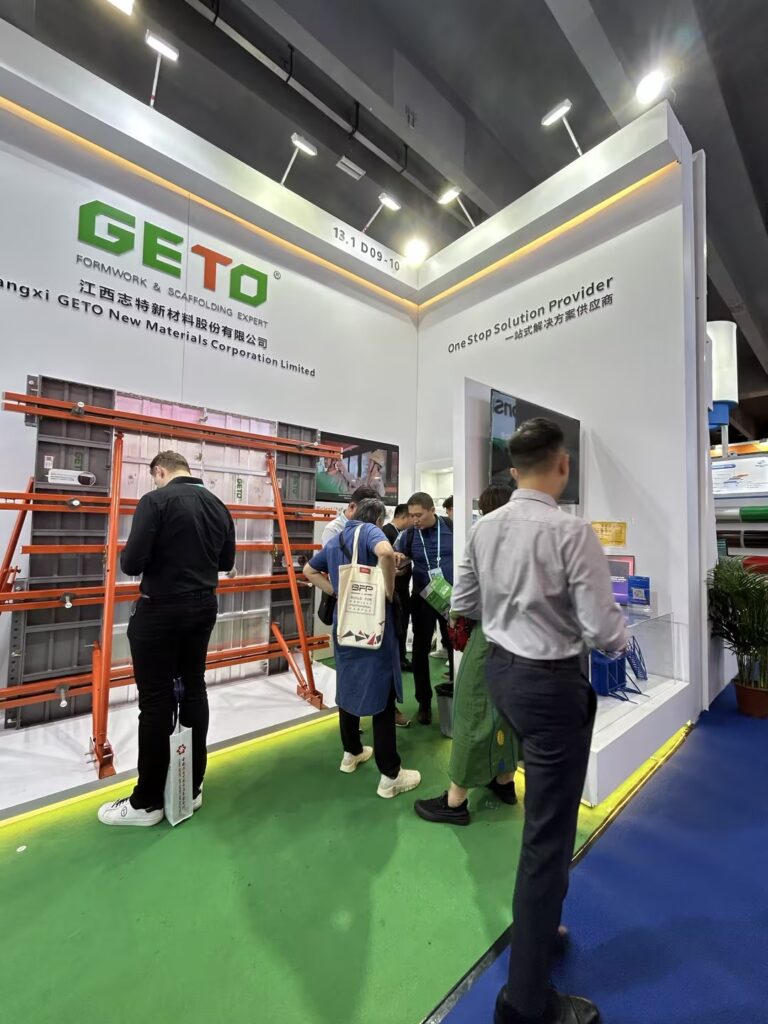

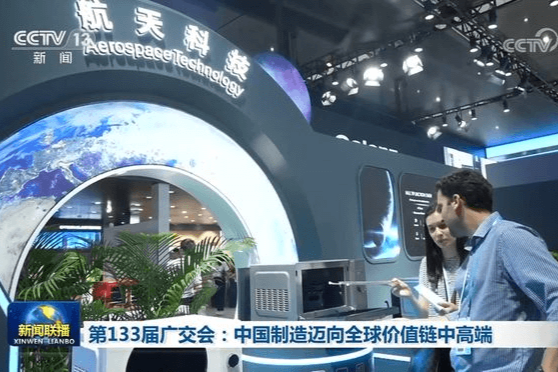

At the 134th China Import and Export Fair (also known as the “Canton Fair”) in Guangzhou City on October 23, 2023, Jiangxi GETO New Material Co., Ltd. (henceforth referred to as “GETO New Material”) showed exceptional success with their distinctive products and first-rate service. This event attracted buyers and professionals from all over the world, providing GETO New Material with an opportunity to showcase its innovation ability and global competitiveness.

Our company’s cutting-edge technology and superior products garnered the admiration of numerous prospective clients throughout the exhibition. Many overseas buyers showed a strong interest in our company’s products and engaged in thorough talks and negotiations with company representatives. In addition, our company’s team introduced the characteristics and advantages of its products to the professionals in attendance, giving them a deeper insight into the company.

The successful performance of GETO New Material in the Canton Fair is not a coincidence, but is the inevitable result of long-term adherence to scientific and technological innovation as well as the pursuit of excellence. GETO New Material was established in 2011. Since its founding, our company has been committed to researching and developing innovative building materials, striving to improve its level of technology and service excellence to satisfy customer demand and advance the sector. We always adhere to technical innovation that propels firm development, keep introducing innovative, high-quality building material goods, and offer top-notch services to the global market.

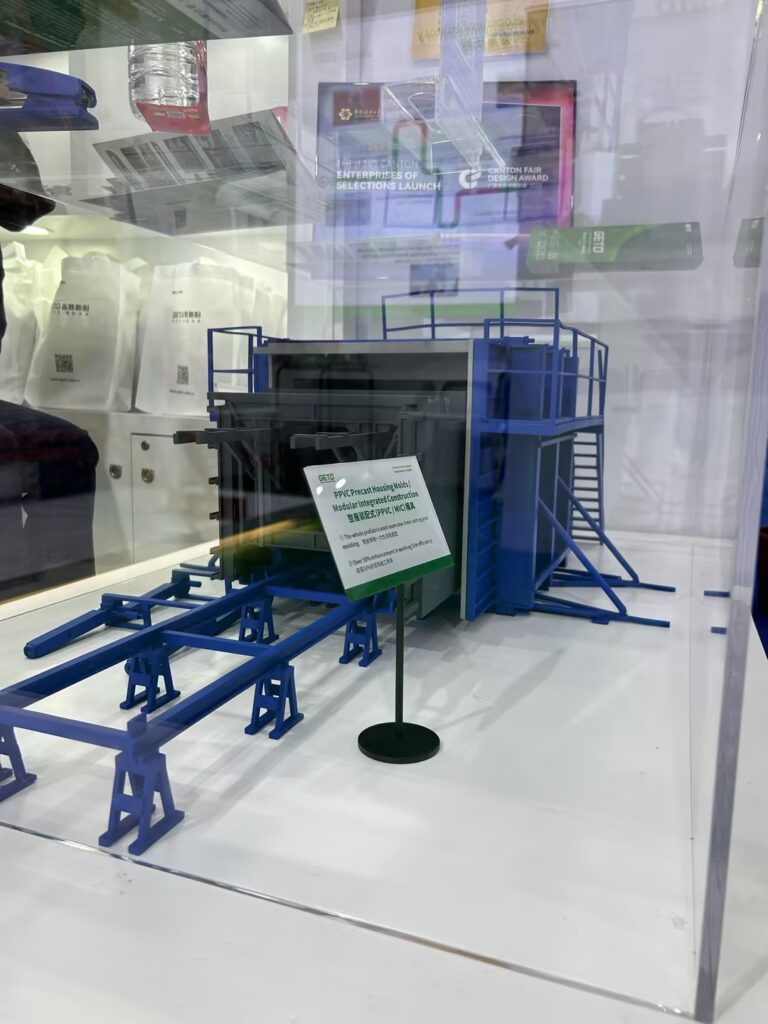

As an innovative company specializing in the research, development, manufacturing, and sales of novel materials, our company showcased its most recent product line at the Canton Fair. Our exhibits covered various new building products and technologies, such as aluminium formwork, self-climbing platforms, one-stop solutions for infrastructure construction, and PPVC precast housing molds, which received enthusiastic embrace and great appreciation from the participants. Among them, the PPVC precast housing mold systems won the gold medal of the Canton Fair Design Award for its green, low-carbon, and high automation production advantages that are in line with environment-friendly requirements.

In the area of environmental protection, our company has also made noteworthy contributions. Beyond creating eco-friendly and sustainable products, we also aggressively advocate for energy efficiency and emission minimization to lower pollution emissions throughout the manufacturing process. In addition to product innovation, we have also worked hard in terms of service. We always adhere to the principle of “Customer First”, offering professional consultation and technical support to ensure that customers can receive satisfactory product and service experiences.

The Canton Fair was a rare opportunity for us to learn and communicate, and also laid a solid foundation for our future development. In the future, our company will carry on with the philosophy of “We create value for customers and work hard to move them”, to further raise the bar for both product and service quality, and to provide more high-quality new building materials for the global market.

Published: Nov 4, 2023

Last published: Oct 16, 2023

The highly anticipated 134th Canton Fair Autumn 2023 is just around the corner, scheduled to be held from October 23rd to October 27th at Canton Fair Complex Guangzhou. As a global construction company, we are delighted to share the news of our participation as an exhibitor, extending a warm invitation for you to explore our booth. We will exhibit our aluminium formwork products, building construction products and decoration materials.

Date: October 23rd to October 27th

Venue: China Import and Export Fair Complex

Area: B Area

Hall: 13.1 Hall

Booth: D09-10

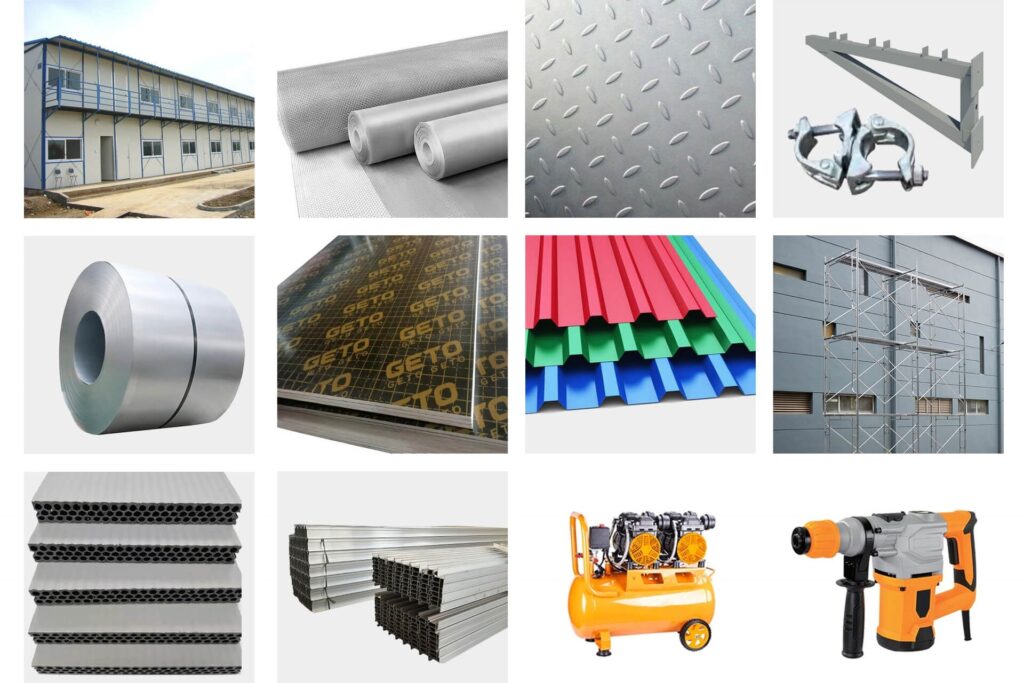

As a global construction company, we are committed to revolutionizing the construction industry with our innovative, high-quality products. Our construction solutions are designed to enhance efficiency, safety, and sustainability. Let’s take a closer look at our offerings:

When contrasted with alternative formwork options, aluminium formwork stands out due to its waterproof and anti-rust properties, making it ideal for time-consuming projects. Our aluminium formwork construction delivers exceptional formwork quality, characterized by remarkable precision and a substantial load-bearing capacity. This not only lowers construction expenses but also ensures rapid construction progress and improved safety measures.

Once assembled, our self-climbing platform remains in use throughout the entire construction process. This leads to substantial cost savings of 30% to 50% per building. It features an all-steel structure, complete integration of equipment, low construction costs, and prolonged utilization, all within a fully enclosed and professionally designed protective system.

Building Materials for Structural Construction

Our building materials are engineered to meet the most stringent structural standards. These materials encompass a range of products, including aluminium sheets, aluminium coils, aluminium beam formwork, and formwork support frames. Together, they assure strength and unwavering reliability.

Our PPVC construction offers distinct competitive advantages compared to conventional building technologies. In contrast to traditional formwork, it can boost construction site efficiency by over 50%. Additionally, it alleviates labour-intensive tasks and enhances safety in the construction workplace.

Our Quick-Deck Formwork System has been designed to rapidly and safely construct large slab areas with minimal labour requirements. Its speedy installation and disassembly are achieved by adjusting the height of the adjustable props beneath the deck formwork, where the props are raised for tightening and installation purposes.

This innovative framework is designed for wall construction. It is tailored for casting building structures with stringent waterproofing requirements, particularly those where reinforcement via a tie-rod system, such as in basements, is not feasible.

Our table formwork ensures remarkable work efficiency, resulting in labour cost savings of around 50%. It is designed to adhere to the construction schedule, enabling the completion of approximately 5 floors of the structure within one month. Moreover, it guarantees a high-quality concrete casting finish, ensuring an excellent appearance.

The lifting shaft platform system can be elevated one level at a time using a tower crane. The entire system can be reset by contracting and expanding, providing a holistic and mechanized approach to lift shaft construction.

If you have any lingering questions about our offerings, we will address them at the fair. At the fair, we will illustrate our standing as a global construction company and showcase our products through videos, brochures, interactive product displays, and 3D models. This presents an exceptional chance for you to closely examine these pioneering solutions. Our team will also be present to respond to any inquiries you may have.

At GETO, we have solidified our position as a leading global construction company. We mainly engaged in green new-type building aluminium formwork, self-climbing platform, and assembly PC components. We have developed PPVC precast housing moulds, quick-deck systems, single-side wall frameworks, table formwork, shaft platforms, and other building materials for structural construction. Our business segments cover the realms of civil and public construction in Malaysia and Singapore, among others.

As the Canton Fair Autumn 2023 approaches, we encourage you to visit our booth at the Canton Fair Complex and discover first hand how we, as a global construction company, are shaping the industry and improving construction projects worldwide. You can engage with our team, ask questions, and explore the possibilities that our innovative products offer. So don’t miss this chance to partner with a true global construction company. We look forward to seeing you there!

Published: Oct 16, 2023

Last published: Jun 17, 2023

The QR code scanner has been implemented in GETO China for many years, and recently introduced into GETO Malaysia in February 2023.

The function of the code scanner can increase the speed of customers returning panels, which also greatly improves the efficiency of labor services. Compared with the previous traditional method which is one-by-one counting of panels, it is indeed much faster. This also greatly reduces the error rate when counting panels. In addition, the paperless formwork management method is more in line with the green construction concept.

Every single panels no matter big or small produce by GETO will comes together with the QR code. The QR code will stick on the surface of panels, labor just need to scan the QR code with the scanning code gun, The data will automatically enter into the data base.

For the GETO construction project Serenia City, located at Sepang, we have adopted the QR code scanner in managing the materials. The Customer delivers the panels from the site back to our factory. Before returning to the factory, GETO assigns a supervisor to do the packing stuff. The supervisor scans the QR code that pasted on the panel with the GETO code scanner. Workers will pack the panels accordingly after the supervisor scans the panels.

This technology will greatly improve the work efficiency and effectiveness of managing construction materials. In contrast, some other suppliers still use the traditional method of remarking one by one with pen and paper, which requires more manpower and is less efficient. This technolgy shows that GETO put much effort into research and development. We provide excellent service to customers and make both of the parties work easier with our technology development.

Published: Jun 17, 2023

Last published: May 31, 2023

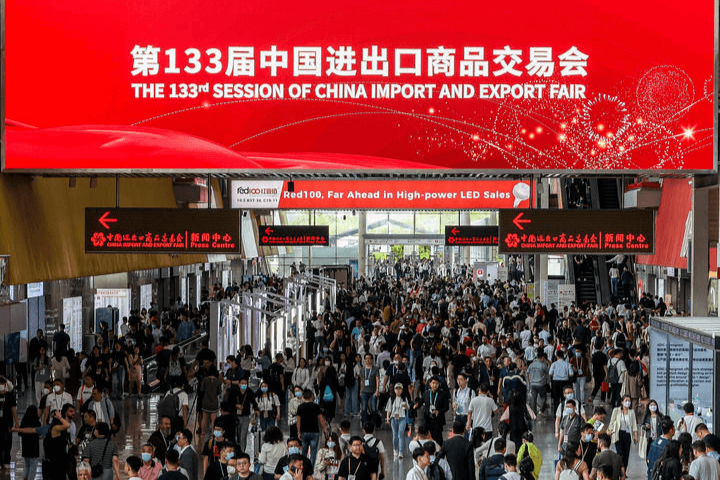

On the 15th of this month, the 133rd Canton Fair was grandly opened in Guangzhou. As one of the aluminum formwork leading enterprises in China, GETO Group participated in the exhibition with a number of products!

The 133rd Canton Fair is the largest in history, both in terms of total exhibition area and number of exhibitors. There were about 35,000 offline exhibition enterprises, with more than 9,000 new exhibitors, and nearly 40,000 online exhibition enterprises uploading more than 3 million pieces of exhibits. The Canton Fair has attracted about 35,000 enterprises and buyers from over 200 countries and regions to participate offline. According to statistics, 370,000 visitors attended on the opening day.

At the fair, we presented its self-produced GETO aluminium formwork with panels, staircases, columns, and other aluminium accessories, providing visitors with a better understanding of our products in a vivid and comprehensive combination form. In addition, we also displayed formwork materials and buildings construction products, such as ringlock scaffolding system, hardware tools, plastic formwork, PVC pipes, couplers and etc. With our marketing team’s communication and presentation, the products were clearly understood and widely praised by exhibitors and agents.

As a one-stop solution provider of building materials, GETO China has been actively participating in the Canton Fair since its establishment 10 years ago. We have always attached importance to each Canton Fair. GETO always adheres to the customer-oriented concept and constantly develops and upgrades our products, sparing no efforts to provide high-quality products, services, and solutions to the customers.

The gathering of thousands of businesses reflects the accelerating release of economic vitality in China. GETO, as one of the leading aluminum formwork enterprises in China, shares the dividends of the Chinese market and promotes the common prosperity and development of the world economy in the same direction with its large scale, the most complete variety of products, and good molding effect.

Chinese manufacturing is moving up the global value chain

At the fair, the number of exhibitors reached a record high, including individual champions in manufacturing and state-level high-tech enterprises. Chinese manufacturing is moving toward the middle-and high-end of the global value chain.

GETO’s Vision

As the global epidemic gradually eases and the global economy recovers, the international and domestic market demand will further expand. With the sincere “win-win” cooperation concept, GETO will contribute to promoting Chinese aluminum formwork system construction technology and excellent products from China to the world.

Published: Apr 30, 2023

Last published: Apr 17, 2023

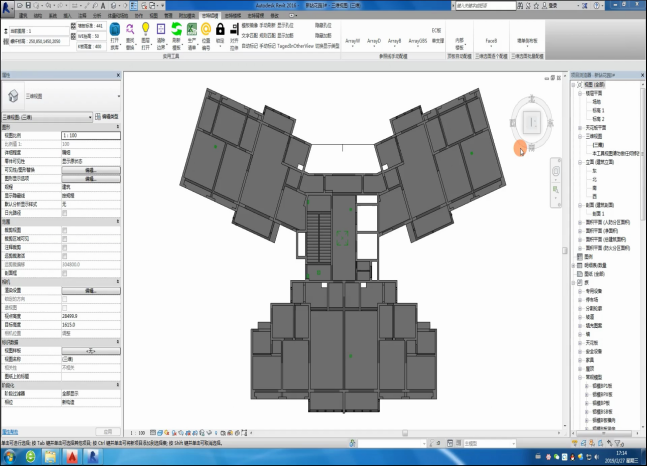

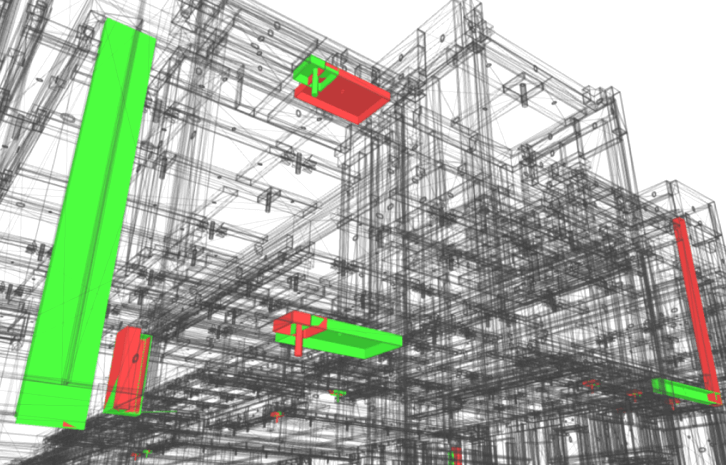

GETO continuously upgrades product service, especially for calculation & modification reuse panels. To fully utilized typical formwork panels & retain formwork panel system design features in exact accordance with the architect’s and engineer’s design.

Our professional team designs a higher rate of standard aluminum formwork panels & versatility on the next project, utilization of used formwork panels is high.

The efficiency of intelligent panel matching is higher, the panel matching time is reduced by more than 50%, and the delivery time is shortened which greatly reduces the frequency of non-site changes, saving time and labor costs for the contractor.

GETO provide services for existing customer with a feature of the high overall value that could refurbish, flip and reuse repeatedly. Also, improving the utilization rate of the existing panel for the next project, effectively reduce the cost.

GETO has provided aluminium formwork system to a customer who is in Bandar Bukit Raja, Malaysia. Through our GETO – BIM System, the formwork setting & installation is simplified, and easy to rectify if there is any error. Not just only projected construction area can be divided part by part or zoning, and calculated reused panels from the intermediate unit to the corner & end unit. Which improve work efficiency compared to conventional modulation system.

Published: Apr 17, 2023

Last published: Mar 30, 2023

On the morning of March 23, GETO Group grandly held a groundbreaking ceremony for its Guangdong-Hong Kong-Macao Greater Bay Area Headquarters Project Phase II. GETO New Material is mainly engaged in green new-type building aluminium formwork system, self-climbing platform, and assembly PC components. Our business segments cover the fields of civil and public construction. At present, we have established more than 10 production bases around the world, and our products sell well in more than 30 countries and regions.

Published: Mar 30, 2023

Last published: Mar 17, 2023