GETO continuously upgrades our built-in Information Technology System that covers both ERP system and CRM system. Backed up by advanced information technology in place, GETO has realized modernized, integrated, and standardized information flow management. Meanwhile, GETO can offer custom-made information system services, including an ERP warehousing system for our clients upon payment done.

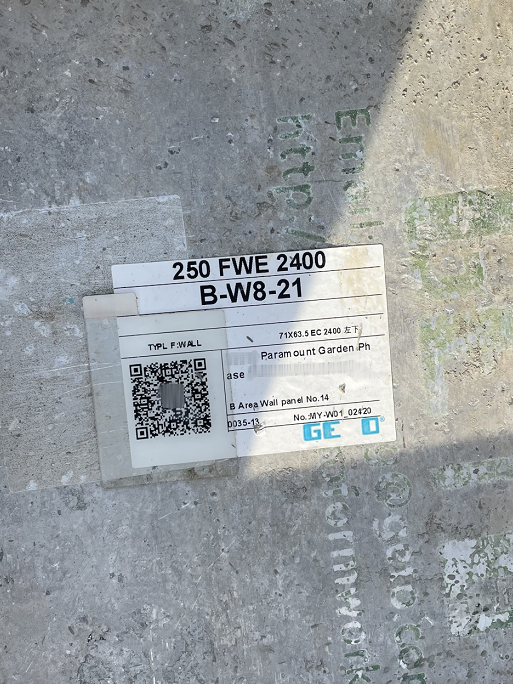

GETO will put the QR code sticker with the information such as the tower details and the location of the materials that shall be used. Like 250 FEW 2400 is the panel specification or B-w8-21 is represented the location of the panel. A scanner device shall be used during the material is ready to pack and GETO will scan all the stickers on the material to make sure there is no material missing before packing and avoid insufficient material on site.

GETO has provided the aluminium formwork system leasing service to a customer where One City Residence in Penang, Malaysia. GETO assigned the supervisor to use the scanner while returning the aluminium formwork at the construction site to ensure that the material is returned and it can help to identify which materials were lost. It also helps customer to save time on returning the aluminium formwork system while the leasing period is ended. Compared to some other traditional suppliers in the market who would do the record by handwriting, GETO is more efficient and time-saving.

Published: Mar 17, 2023

Last published: Feb 28, 2023

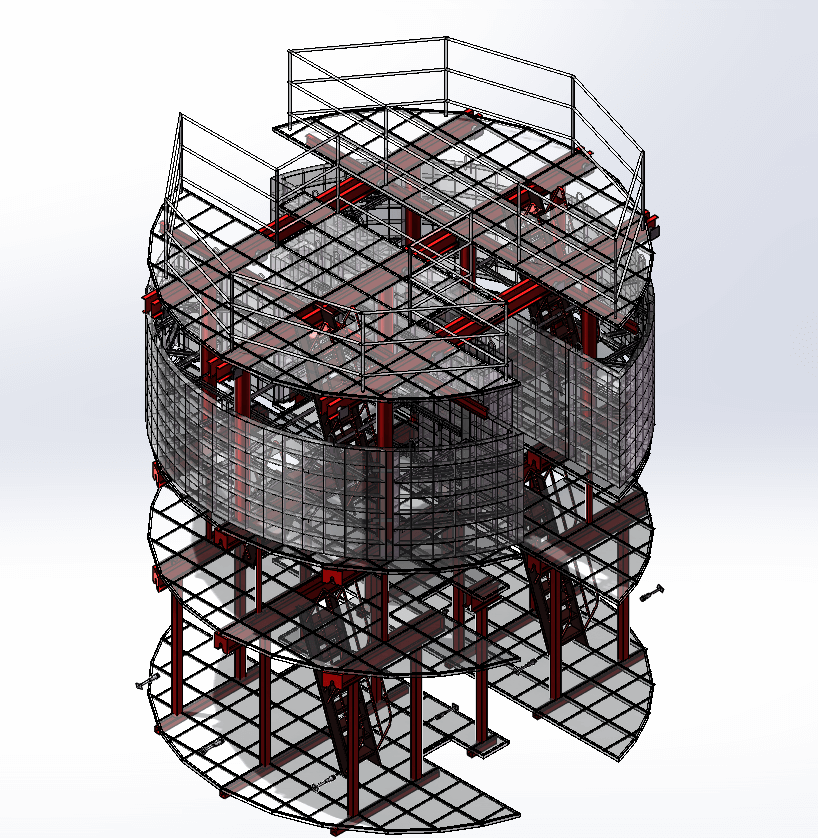

GETO Hydraulic self-climbing formwork is the optimal solution for the cores of super high-rise buildings (over 150 meters), including both concrete core walls and frame structure cores, as well as for shear walls.

It is made up of formwork panels, a climbing mechanism, a working platform, hydraulic jacks, and a power unit. The formwork panels are used to create the shape of the concrete structure, and the climbing mechanism, which is powered by hydraulic jacks and a power unit, allows the formwork to be raised or lowered vertically as the structure is being built. The formwork panels are typically made from materials such as wood, steel, or aluminum. The hydraulic system is powered by a motor and uses hydraulic cylinders to move the formwork up and down the structure.

As the formwork system climbs up the building, the workers install new formwork on the next level and pour concrete into the formwork. Once the concrete has hardened, the formwork is removed and the process begins again. The hydraulic system ensures that the formwork system remains stable and level as it climbs, which helps to ensure the quality and safety of the construction process. The working platform provides a safe and secure area for workers to carry out their tasks at high elevations, which can reduce the risk of accidents and injuries on the job site.

The system’s obvious advantages have been verified in plenty of projects both at home and abroad:

Not only in super high-rise buildings, but GETO hydraulic self-climbing formwork system is also widely used in the construction of bridges, dams, and other large infrastructure projects.

More specifically, GETO hydraulic self-climbing formwork is suitable for projects that require a fast and efficient construction process, as the system is designed to be quickly erected, dismantled, and moved to the next location. This makes it an excellent choice for projects with tight construction schedules, where time and labor costs are critical factors.

If you want to further inquire about the GETO formwork price list, please feel free to contact us!

Published: Feb 17, 2023

Last published: Jan 30, 2023

In the year of 2022, GETO, the “1+N” one-stop solution provider, has worked with international clients to create a series of excellent construction projects. We selected 12 of the most representative projects, let us take you to enjoy the charm of green and smart buildings.

The project is a 26-storey high-rise project in a prime location in Hung Hom, Kowloon, a masterpiece of large-scale integrated urban redevelopment.

Considering the high cost of labor resources in Hong Kong, GETO provides formwork solutions to improve construction efficiency and save labor costs.

Project highlights:

① Use the lightweight aluminium formwork, which is easy for construction team to assemble and disassemble the formwork system.

② Adopt the lifting shaft platform system. In the construction process, the lifting shaft platform system of the elevator shaft can be lifted layer by layer by tower crane, and can be retractable and reset, which made the construction of the elevator shaft become integrally and mechanically.

The T1210 Villa project is a large-scale housing construction project built by the local Housing Welfare Department, covering a total area of 628,000 square meters.

The traditional local construction habit is to use timber formwork.This project is the first introduction of aluminium formwork technology in the local housing construction field. GETO’s high-quality products and professional services have been highly praised by customers, and GETO also promoted the development of aluminium formwork construction technology in the housing construction market in this region.

Project highlights:

① GETO provides the design and construction scheme to maximize the utilization rate of aluminium formwork, including the mutual turnover of the different formwork sets and the mutual utilization of the mirror house type’s formwork;

② In the early stage of the project, in order to cooperate with the project approval of customers, GETO provides pre-design service for customers, and improves the design scheme by referring to the local architectural design code, so as to help customers get the approval smoothly.

The project consists of 11 buildings are constituted by 2,444 prefabricated modules in 91 structural types.

Project highlights:

① Considering the characteristics of the prefabricated unit in this project, which is used more times and has a variety of prefabricated unit structures, GETO and its partners jointly developed an automated and intelligent PPVC PRECAST HOUSING MOLDS, and made a detailed turnover plan and scheme of the formwork for the customer. Finally, client only used 35 sets of automatic PPVC PRECAST HOUSING MOLDS, 17 sets of non-automatic PPVC PRECAST HOUSING MOLDS and a small group of construction teams to complete the main structure construction of this gorgeous property!

② PPVC construction technology reduce the labor demand and labor cost of the construction site to the greatest extent, the high construction efficiency and convenient concrete pouring way obtain the customer’s praise!

San Ying Rapid Transit Station is a new rapid transit station planned and constructed by the Taiwan Government of China. This project is a special structure of the subway station, with a total of 8 floors and a large number of changes in each floor. Our company provides our customers with the aluminium formwork design scheme that maximizes the re-utilization of the old formwork and reduces the material cost of purchasing aluminium formwork for our customer.

Project highlights:

① Re-utilize the aluminium formwork of standard floor maximally to the rest of the changing floors;

② GETO’s design team spent 5 months in numbering the aluminium formworks one by one to solve the problem that the construction workers of the client had difficulty in finding the turnover of the old formworks during the construction process.

For the project with special structure and many changing floors, our company finally provided the perfect design solution, which was highly recognized by the customer!

Egypt’s El Alamein Ultra-High Complex project D01M is an important strategic urban core building in the Egyptian government’s Vision 2030 plan and another typical example of China-Egypt cooperation under the Belt and Road Initiative.

Project highlights:

① The project is a special shape structure, and there are arc-shaped floating plates with odd and even changes outside and the area is reduced layer by layer.

② The top panel of the project is prestressed panel, and the prestressed panel exists in a conflict between the prestressed system and the formwork system of GETO. At the same time, the customer requires to use their own ringlock scaffolding system in combination with the aluminium formwork of GETO. In response to the project situation, GETO provided a design scheme with a combination of aluminium formwork and timber formwork. The scheme was also highly praised by the customer!

Urban Village, a super high-rise residential project with more than 50 floors, is a new landmark of this country’s capital, and a large community where local new culture is most popular.

Project highlights:

① Spent 1 year in structural construction drawings docking communication, assist customers to solve the defects of the preliminary project construction drawings;

② GETO provides a design scheme which let two standard floors to share a set of aluminium formwork, re-utilize the changing floor formwork to the standard floor formwork, maximize the usage of formwork, to help customers save material costs.

③ This project has a duplex building structure, and the hollow floor in the structure is a big difficulty. GETO tailor-made a set of aluminium formwork support reinforcement scheme for the hollow floor for the customer.

④ The project finally completed the re-utilization of more than 10 floors of changing floors , achieve the maximum value of the usage of the aluminium formwork.

Occupy an area of 65 acres, D ‘Vine, the Malaysia’s 52-storey super high-rise apartment, is an affordable serviced apartment in a township mixed development in Kuala Lumpur.

Project highlights:

① The structure of the podium and the tower of the project is very different, and the storey height is not the same. Through the optimization of the building structure, GETO improves the standardization rate of the formwork, so that the standard and non-standard floors in the same building can use the same set of formwork system.

② In the turnover design of podium formwork, GETO provides aluminium-timber combination and formwork reinforcement scheme to help customers save materials and construction costs, and solve the pain point of high cost of non-standard formwork.

③ Aluminium formwork is used for the construction of a full set of structural buildings in the podium building, including the horizontal structure and column cap parts which are not commonly used aluminium formwork, and better pouring and forming effect was achieved.

The public housing is located at Lot B10, Zone A of Macao New City, covering an area of 6,831 square meters. The main uses include residential, public parking, commercial and public facilities. It is a social welfare housing.

Project highlights:

① Introduce advanced design ideas from other regions in the international market, actively communicate and cooperate with customers to overcome regional differences in technical specifications and construction habits;

② GETO uses the self-developed “BIM Industrial Design Software — Xiaozhi” to help customers with accurate formwork modulation. The technical advantages of automatic formwork modulation, correction and design, enable the aluminium formwork system of GETO to achieve ultra-high design quality without physical trial assembly.

The large residential project is a public tender of the Kaohsiung City government, a major focus of the housing and urban renewal Center in Taiwan, China.

Project highlights:

① The standardization rate of the formwork of this project reaches 85%, which greatly improves the construction efficiency and facilitates the mutual re-utilization between different block’s formwork.

② For the special points in the project, GETO helps customers to carry out special optimization and treatment: The installation of edge protective net enhances the security of formwork installation; The window sills are sloped to improve the water resistance of the house as a whole.

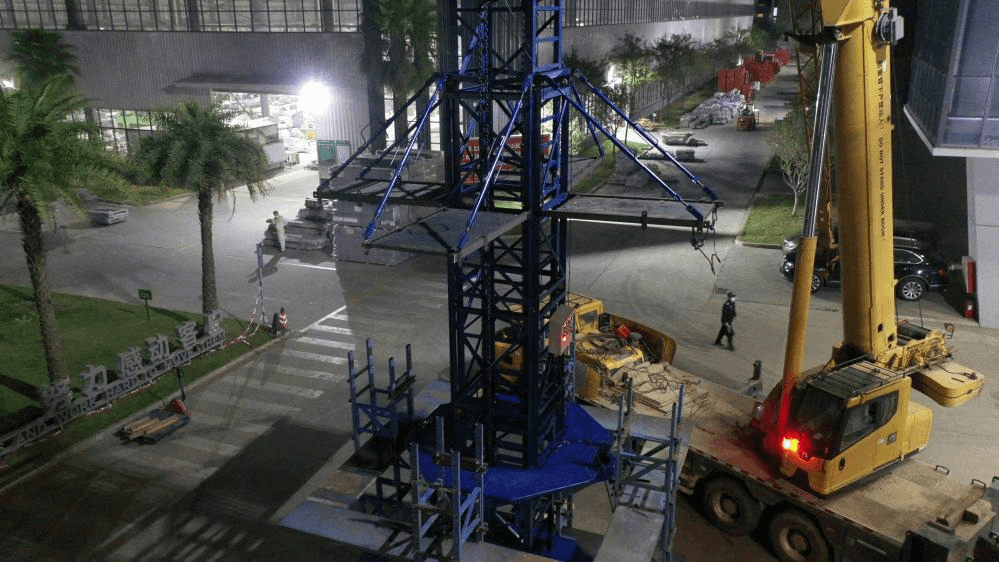

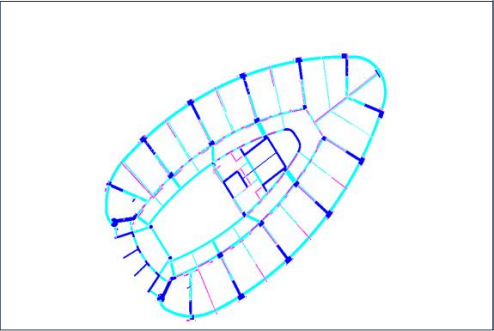

Conceived by PUB as a cost-effective and sustainable solution to meet Singapore’s long-term needs for sewerage collection, treatment, recycling and disposal, the Deep Tunnel Sewerage System (DTSS) is a signature public project of the Singapore Government. We were very fortunate to be involved in the DTSS2-T11 project as a supplier of shaft formwork and construction platforms.

Project highlights:

① The construction site of the project is under the shaft platform in the tunnel, and the construction space is too small to use large machinery. In order to solve the difficulty, the R&D team of GETO adopts the suspension construction scheme, installs the attached self-climbing system on the shaft platform, and realizes automatic climbing of mechanized equipment, reduces labor, improves construction efficiency, and solves the problem of narrow construction space.

② This project involves a large shaped circular steel formwork with an inner diameter of 13.5m, which is different from the general steel formwork reinforcement. GETO use the reinforced channel steel to make the steel formwork more firm and the forming effect better. At the same time, the large-shaped circular steel formwork manufacturing is also a major innovation breakthrough of GETO’s production technology.

③ The shaft construction platform is equipped with sensors and stoppers, and intelligent electronic control is adopted to ensure the stability of the frame structure and safe lifting.

④ Customized scheme design according to customer requirements: redesigned the special-shaped walkway plate, adjusted the height of the construction platform, and optimized the shaft platform model according to the force calculation.

This project is a serviced residential apartment project with a building area of 3,367 square meters, which is a typical hotel apartment in the area.

This is the first time for the client to use GETO’s aluminium formwork products for a hotel project. GETO is able to provide customized products and service solutions for different international markets.

Project highlights:

① The project is a complex re-utilization project, re-utilize another different structural type hotel’s formwork in this project. GETO carefully provides economic and technical solutions for aluminium formwork system, which not only saves cost for customers, but also meets the requirements of customers’ on-site construction.

② In combination with local design specifications and local construction habits, GETO has optimized the formwork structure for many times to meet customer needs.

IBN Highlands City is a multi-billion dollar landmark commercial project in Malaysia. It is located in the Genting Plateau, the largest summer resort in Asia. The project combines serviced apartments, a business district and a five-star hotel.

Project highlights:

① The project has great floor height, many changing floors with special and complex structures; including round columns, arc-shaped beams, decks with special angles, etc, special-shaped formwork accounted for more than 50%.

② GETO uses self-developed intelligent formwork modulation software to design and optimize the structure of the project’s formwork. Before the formwork delivery to the construction site, it has carried out several intelligent assembly tests in factory, which helps the project finally realize zero defects!

Published: Jan 30, 2023

Last published: Jan 17, 2023

This is the first formwork re-utilization project in Taiwan, China, which means most of the formwork are re-used from previous projects, with only a small portion to be provided additionally.

Such projects require substantial collaboration with customers, high accuracy in formwork re-design, and foresight of possible difficulties and counter plans. Limited time makes it even more challenging.

With close collaboration between both parties and construction work nicely orchestrated by our customer, the project is progressing well on schedule with quality outcome.

However, the consideration of formwork reuse does not merely start from the beginning of this project. Instead, it starts at the very beginning of the time. At the very beginning of the first project, the GETO design team communicates with the customer in detail about floor height, and structural features, also with an eye on all other projects in the customer’s project pipeline. This is to determine a versatile principle of formwork modulation for those projects, with a certain standardization rate that is mutually agreed upon. In the case of this customer, the standardization rate is set at more than 80%.

When the project is finished, the used formwork and aluminum formwork accessories are properly cleaned and stocked following GETO relevant guideline.

When it comes to a new project, in which the formwork is to be re-used, a detailed formwork list and zone-wise packing instructions will be given. It clearly tells what panels and aluminium formwork accessories shall be re-utilized, and specifies they are to be used in which room/zone. In this way, site workers don’t have to spend extra time searching for the right formwork piece. This is how a smooth and well-organized re-utilization of aluminum formwork can take place.

At GETO, we care more about how our customers could make the right investment, not only through providing reliable and quality products; but also by helping them activate their formwork stock to achieve the best value in utilization in the long term. GETO prides ourselves on our positioning as a trusted partner instead of a formwork vendor.

Published: Dec 30, 2022

Last published: Dec 17, 2022

As we all know, transport is of great importance to both social and economic development. In Taiwan, China, new MRT stations are being built for the public’s benefit and convenience. GETO is proud to have been involved in one of these projects supplying construction materials. We supplied aluminium beam formwork, aluminium wall formwork, aluminium deck formwork, and aluminium column formwork, single-side formwork is also included.

When it comes to retaining walls, we usually use large triangular trusses to build them. However, the large triangular trusses are so large and heavy that they must be lifted and moved by crane and cannot be installed by manpower only. A bar implant solution is relatively light but requires more pre-set operations. The client gave us their ideas, wanting to be able to install it manually without using the crane, not a tie rod embedding plan, and to use aluminium formwork for the construction. Our international R&D team finally provided an Aluminium Beam Type Single-Side Wall Framework solution, which not only meets the customer’s requirements for manual operation and less implant as mentioned above but also increases the turnover utilization rate of each component, as aluminium beams and props components can be used in other floors and structures after the retaining walls are done.

Thanks to the joint efforts of the client and us, the formwork was installed with a high degree of completion and the finish was quite satisfactory. The customer has actively provided us with feedback on the use of the product on-site, which has helped us to continue to optimize the product and meet the requirements of the site. In addition, Single-Side Wall Framework can be used for wind energy farm construction.

GETO also provides a Triangular Truss Type Single-Side Wall Framework. Two types of single-side wall formwork each has its advantages with aluminum beam type single-side support formwork.

Published: Nov 30, 2022

Last published: Nov 17, 2022

The BAKER CIRCLE.DOVER project is a 26-story high-rise residential project. Located in Kowloon’s prime location of Hung Hom, “BAKER CIRCLE” spans a total commercial and residential floor area of over 1,000,000 sq. ft.2, standing as a large-scale comprehensive urban redevelopment masterpiece that is rarely seen in the past 30 years. The project uses GETO combined aluminum formwork and precast concrete(PC) components for integrated construction, helping the Hong Kong construction industry to transform and upgrade to industrialization, intelligence, and green.

-1024x576.png)

-1024x576.png)

Linked up with several major roads, this redevelopment incorporated its own brand-new 3-dimensional shopping streets, created with concepts of sustainable environment, world-class architectural and design aesthetics, cutting-edge smart living gadgets, and a wealth of innovative clubhouse facilities. “BAKER CIRCLE”1 is set to redefine the ideal contemporary lifestyle.

The project is equipped with four sets of steel supports (five sets of the cantilever), and the construction speed of the workers on the construction site can reach four days per floor. Compared with traditional formwork, the project construction period is greatly reduced and great value is created for customers.

The average daily wages of construction workers in Hong Kong are extremely high. GETO provides professional guidance on installation services to improve the efficiency of aluminum formwork installation for on-site personnel. It also shortens the construction period, which can significantly reduce the labor cost of workers.

The turnover of aluminum formwork in this project is more than 20 times, and the construction of all standard layers can be completed by using one set of aluminum mold, with a low average cost of use.

The aluminum alloy formwork system with an average weight of 25KG/㎡is simple and convenient to assemble. It is completely assembled by hand and does not require the assistance of any mechanical equipment. Workers usually only need a small hook and a small hammer for construction, which is convenient and fast. Skilled installers can install 20-30 square meters per person per day. Compared with wooden formwork, the advantages of aluminum formwork are more obvious. Aluminum formwork installers only need 70-80% of wooden formwork installers, and there is no need for skilled workers, as long as simple training is given to the construction workers before installation.

After the aluminium formwork system is assembled, it forms a whole framework with good stability. With the reasonable arrangement of load-bearing pillars, the bearing capacity can reach 30KN per square meter.

After concrete casting and removing the formwork, the surface of the concrete is smooth and clean, which can meet the requirements of finishing and fair-faced concrete without plastering and can save plastering costs.

The aluminum mold uses renewable materials, which can effectively help energy conservation and emission reduction. It is a green building material. At the same time, the project’s prefabricated laminate panelsand prefabricated stairs reduce the generation of construction waste on the site.

The project also used the GETO Shaft Platform and successfully helped solve the pain points of the customer and improve construction efficiency. The lifting shaft platform system can be lifted layer by layer through a tower crane. The whole system can be reset by contraction and expansion, which makes the construction of the lift shaft holistic and mechanistic.

Shaft Platform solved pain points :

.png)

Published: Oct 30, 2022

Last published: Oct 17, 2022

GETO Malaysia participated in a significant landmark project in the middle of Genting Highland, wellknown summer retreat in Malaysia. It is IBN Highlands City – A billion-dollar project developed by IBN Corp Ltd. GETO empowers the construction industry around the world with high aluminium formwork productivity.

IBN Highlands City is a mixed development project (serviced apartment and hotel), which was designed based on the imaginative visuals of several pieces of flower petals placed in the midst of clouds of the cooling highland. The project has a total built-up area of 8,400,000 sq ft.

Within the 4978.52 ㎡ aluminium formwork construction area the project consumes in total, GETO Malaysia supplied 2166.83 ㎡ of the aluminium formwork system. In the system, GETO Malaysia supplied 400 ㎡ systems, which are round edges and arc-shaped columns. The special design of IBN Highlands City that is largely different from common typical structures creates challenges for the construction and precise design of formwork in aluminium factory for the project.

With GETO’s intelligent formwork software, BIM Modulation Design in place, special structures are no longer a real challenge since every structure in the AutoCAD drawing of IBN Highlands City can be quickly checked in place at one time. This patented software of GETO Group can automatically identify walls, beams, slabs, and other structures with 100% precision attained.

In addition, GETO’s intelligent BIM Modulation Design Software can facilitate the client to achieve an ideal state in maximizing the reusability of the client’s existing aluminium panel in adoption together with the GETO aluminium formwork system.

Upon the delivery of the aluminium formwork system to the site, GETO site supervisors stayed with the project for at least one month. They are committed instruct the workers on site to appropriately fix the structure system, while quickly responding to any circumstances related to the formwork system on-site. Because of our outstanding construction engineering solutions, we have done a great job with this project.

Besides the use of the standard panels supplied, the curve-shaped structures formed by special-shaped aluminium formwork systems are in good casting effect as well. This helps the contractor to save up time for crafting the special-shaped by crafting timber formwork on-site, which brings the result of cost-saving in hiring increasingly costing labour in carpeting. Also not forget to highlight, the high durability of the GETO Aluminium Formwork System guarantees the consistency of the casting quality of the project across numerous floors it is being reused.

Published: Sep 30, 2022

Last published: Sep 17, 2022

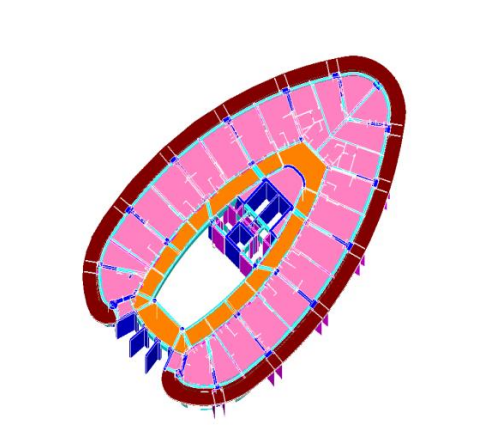

One of GETO’s customers has studied special building structures to protest against earthquakes. Their company mission is to provide solutions to save lives and deliver affordable housing in earthquake-prone areas. Finally, the local government highly appreciated and recognized their building solution, which adopted the GETO Precast Concrete.

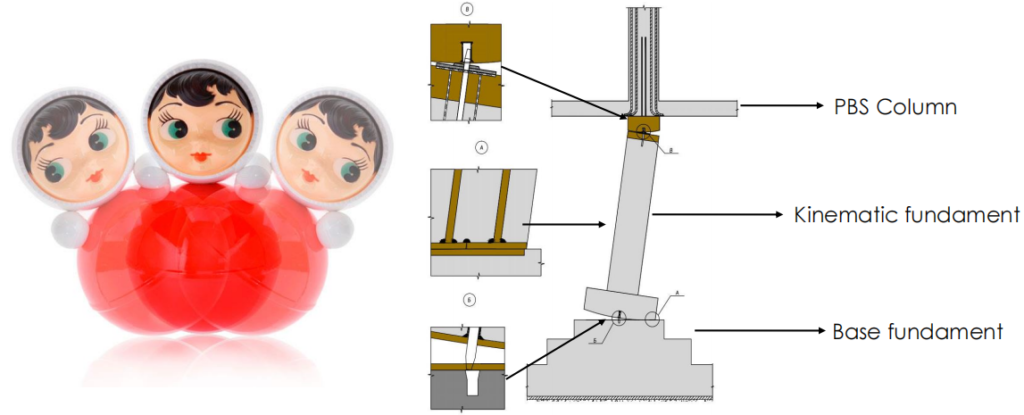

Seismic isolated fundamental work on the same principle as a“tilted doll”. Unlike other seismic isolation system, it doesn’t require any regular maintenance. GETO Precast Mould System helps clients save a lot of money for later maintenance.

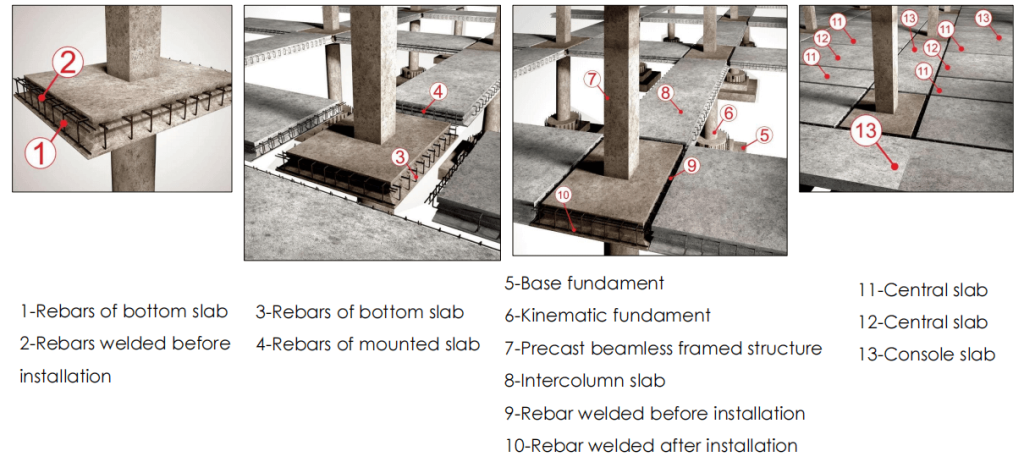

The clients provide the architectural plan, elevation plan and section only, there is no structural plan, because it’s beamless structure. However, they require us to provide aluminium forms for the column parts. it’s not the same as normal square columns. The difference is that we need to reserve several holes for steel rebar and those holes should be open precisely, here let me share some attached photos from GETO precast factory. Our customer calls it as “PBS” column.

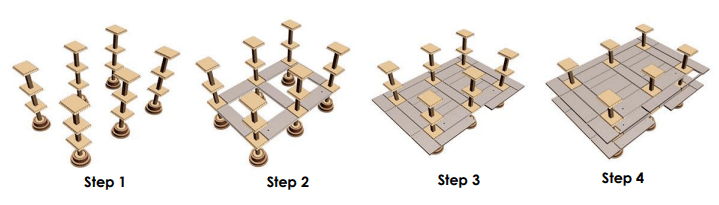

This precast formwork system has two main components that can be used independently. The factory produced precast columns and precast slabs are combined and welded on site. No beams are required that reduces building weight, cost and time of construction.

Published: Sep 17, 2022

Last published: Aug 30, 2022

In Taiwan, China, the government is planning new MRT stations, of which the Sanying MRT station is under construction. GETO has proudly supplied aluminium formwork system for wall, beam, deck, column etc, including inclined columns.

The dimensions of the largest inclined column on site are as follow:

Length of column base section: 2300mm

Width of column base section: 2300mm

Vertical height of column: 14253mm

Length of beveled side of column: 15222mm

Angle: 69.45°

MRT are closely related to people’s lives and being able to build MRT stations with aluminium formwork is an important step forward in GETO’s involvement in public construction projects in Taiwan.

In this project, due to the special structure, it is necessary to adopt large leaning columns, which are more difficult for our aluminium formwork design, but we did it perfectly.

Large leaning columns mean that stronger support and reinforcement systems, more accurate design and production, and strict site management are required – all three of which are essential.

① GETO solves it with tie rod system, which ensures the security and efficiency of the project. GETO formwork class products can be applied to different project types and high turnover of formwork between different structure types and typical floors can be achieved.

② GETO uses self-developed software of modulation, such as BIM, Auto CAD and 3D Modulation Software to offer the clients. These technologies provide technical support for the customer’s project, promoting it to be successful.

③ In this project, GETO provides 24 hours online technical support for customers to solve the technical problems when using our aluminium column formwork, so as to be customer-center and give customers a good experience.

Published: Aug 30, 2022

Last published: Aug 17, 2022

This project consists of 11 towers, formed by 2444 precast modules of 91 structural types. GETO supplied 35 sets of automated precast mould and 17 sets of non-automated precast mould for turnover in casting in this project.

GETO supplied 21 sets of automated precast mould for turnover in casting 38 precast modules in this tower.

Related article:

https://www.getoformwork.com/industry-news-articles/ppvc-housing-precast-formwork-system-geto/

https://www.getoformwork.com/enterprise-news-articles/geto-ppvc-housing-precast-formwork-system/

#PPVChousingprecastformworksystem

Published: July 17, 2022

Last published: June 30, 2022