GETO Malaysia participated in a significant landmark project in the middle of Genting Highland, wellknown summer retreat in Malaysia. It is IBN Highlands City – A billion-dollar project developed by IBN Corp Ltd. GETO empowers the construction industry around the world with high aluminium formwork productivity.

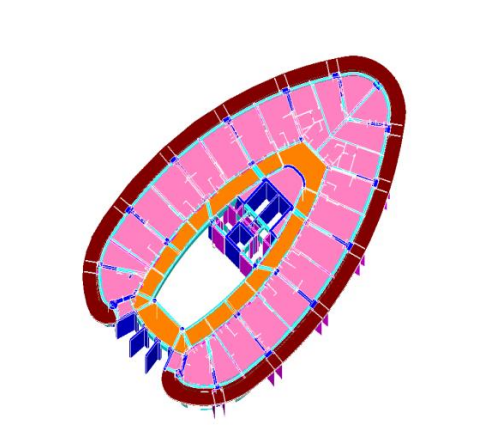

IBN Highlands City is a mixed development project (serviced apartment and hotel), which was designed based on the imaginative visuals of several pieces of flower petals placed in the midst of clouds of the cooling highland. The project has a total built-up area of 8,400,000 sq ft.

Within the 4978.52 ㎡ aluminium formwork construction area the project consumes in total, GETO Malaysia supplied 2166.83 ㎡ of the aluminium formwork system. In the system, GETO Malaysia supplied 400 ㎡ systems, which are round edges and arc-shaped columns. The special design of IBN Highlands City that is largely different from common typical structures creates challenges for the construction and precise design of formwork in aluminium factory for the project.

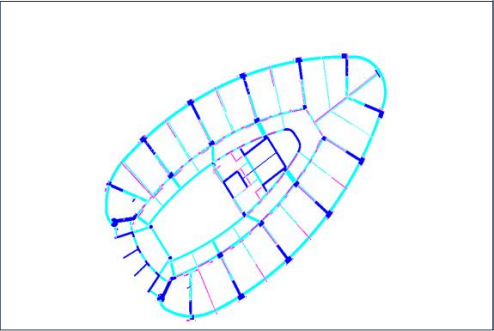

With GETO’s intelligent formwork software, BIM Modulation Design in place, special structures are no longer a real challenge since every structure in the AutoCAD drawing of IBN Highlands City can be quickly checked in place at one time. This patented software of GETO Group can automatically identify walls, beams, slabs, and other structures with 100% precision attained.

In addition, GETO’s intelligent BIM Modulation Design Software can facilitate the client to achieve an ideal state in maximizing the reusability of the client’s existing aluminium panel in adoption together with the GETO aluminium formwork system.

Upon the delivery of the aluminium formwork system to the site, GETO site supervisors stayed with the project for at least one month. They are committed instruct the workers on site to appropriately fix the structure system, while quickly responding to any circumstances related to the formwork system on-site. Because of our outstanding construction engineering solutions, we have done a great job with this project.

Besides the use of the standard panels supplied, the curve-shaped structures formed by special-shaped aluminium formwork systems are in good casting effect as well. This helps the contractor to save up time for crafting the special-shaped by crafting timber formwork on-site, which brings the result of cost-saving in hiring increasingly costing labour in carpeting. Also not forget to highlight, the high durability of the GETO Aluminium Formwork System guarantees the consistency of the casting quality of the project across numerous floors it is being reused.

Published: Sep 30, 2022

Last published: Sep 17, 2022