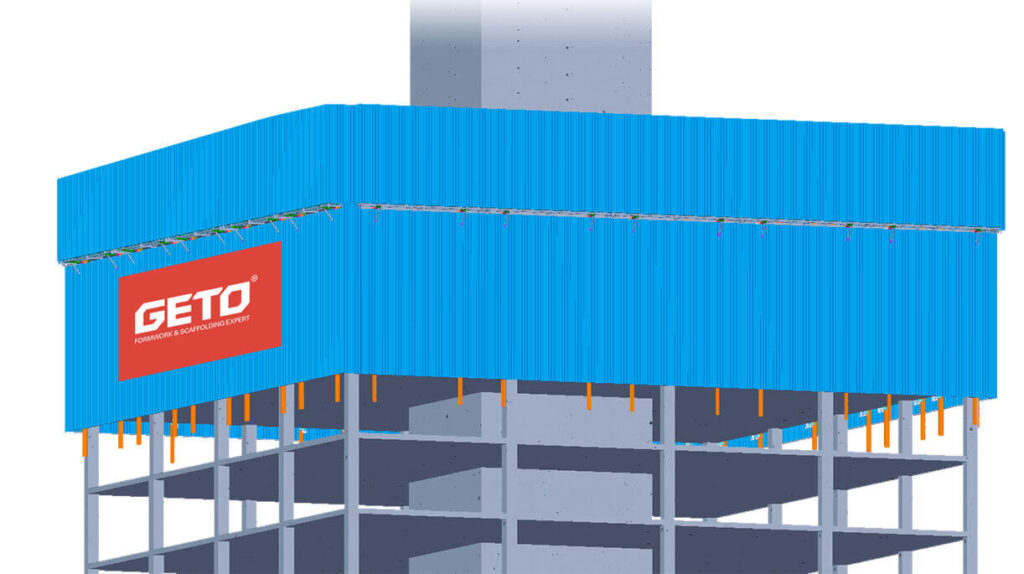

Protection screen is an innovative safety device attached to structures (floors, beams, or walls) and lifted using a tower crane or hydraulic system. Specifically designed to fulfill peripheral protection needs for high-rise and super-high-rise buildings.

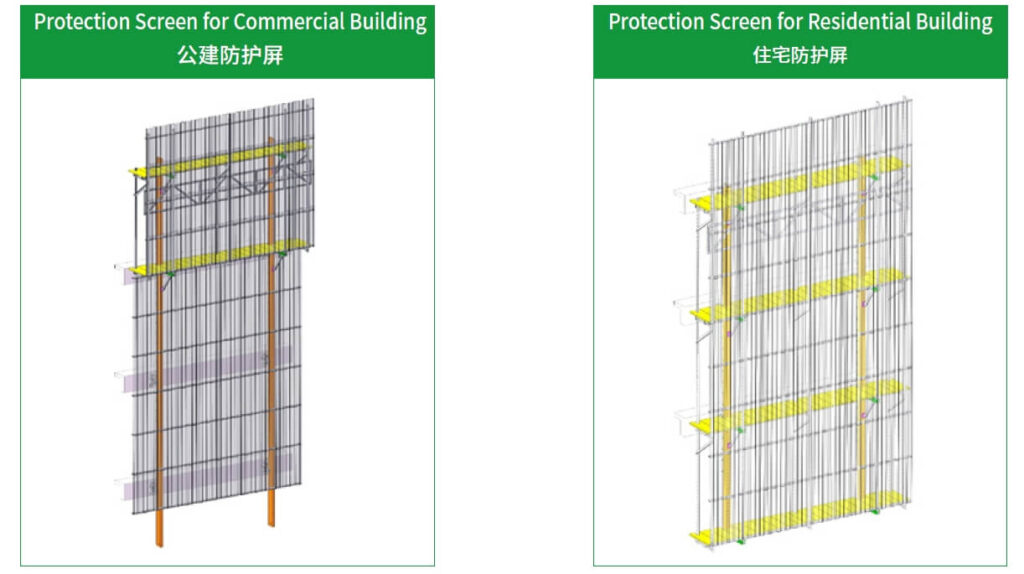

There are obvious differences between the facade walls of commercial and residential buildings. Residential buildings typically have many facades, demanding protection screens for exterior work, while commercial buildings’ fewer facades permit work from internal edges.

Therefore, GETO protection screens are categorized into residential protection screens with more platform layers, and commercial building protection screens with fewer platform layers.

① Guide rails and platform boards are 0.3m from the wall for easy installation of beam and wall formwork.

② Seal flaps can be installed as needed.

High wind resistance

▪ Capable of withstanding a maximum wind load of 9 levels without extra reinforcement. Additional reinforcement is needed for wind loads beyond level 9.

Fall arrest

▪ Fall arrest devices attached during climbing are independent, minimizing safety issues resulting from operational errors.

▪ Protection against personnel and items being dropped is ensured by full sealing, including guide rails, corners, and protruding parts.

▪ All components undergo rigorous testing, including extreme loads and falls, to ensure safety in extreme conditions.

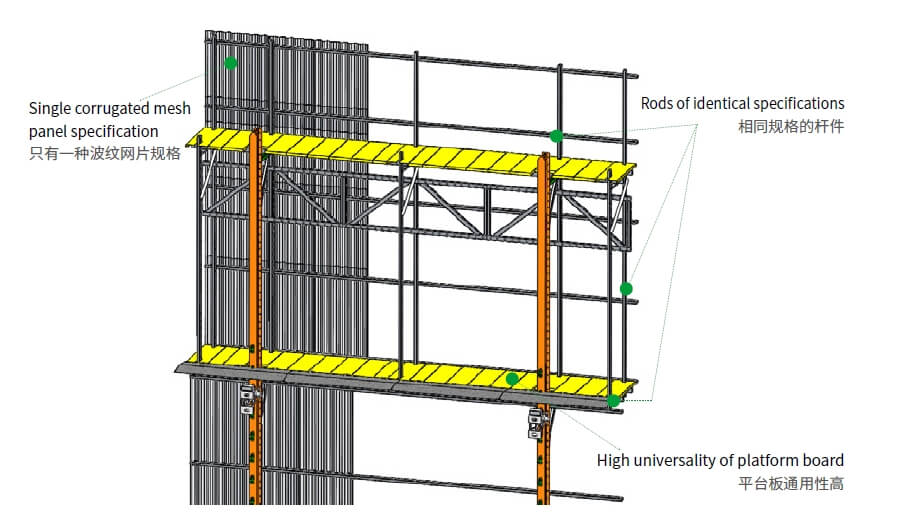

▪ Strong universality of components for easy management.

Main components do not exceed 10 types, achieving a universal compatibility rate of 95% or higher.

▪ Hydraulic drive system.

Compared to conventional protection platform using electric hoists and electronically controlled, the cost is lower.

▪ Reliable, maintainable, and easy to operate.

▪ Lower costs for disassembly, transportation, and labor due to the lightweight frame compared to regular steel climbing platforms.

▪ Suitable for diverse shapes and heights of structure. Adjustable floor supports permit use on facades with both varying and constant inclinations.

▪ Platform boards and sealed flaps can align with floor levels.

| S/N | Item | Unit | Specification | Remark |

| 1 | Framework height | m | 8~13.5 | Adapting framework height to project conditions |

| 2 | Framework width | m | 0.6-1.2 | Standard platform board width: 0.88m |

| 3 | Machine position affecting width | m | 3.5 | Total length varies with machine position count |

| 4 | Single unit weight | T | 1.3 | Calculating based on a 2.5-level protection screen, with a machine position affecting width of 3.5m |

| 5 | Rated lifting capacity of the power unit | T | 3.5 | Hydraulic cylinders, pump station |

| 6 | Power unit capacity | KW | 1.5 | Voltage: 380V/415V, Frequency: 50Hz, Max fuse current: 5A (Motor can be customized based on local electrical specifications) |

| 7 | Single lift height of hydraulic cylinder | m | 0.3 | Effective lift height: 0.3mTotal cylinder stroke: 0.42m |

| 8 | Lifting speed | m/min | 0.3 | |

| 9 | Time for lifting one level | min | 10 | Calculating based on a 3m floor height |

| 10 | Platform load capacity | kN/㎡ | 2 | Operating on a two-level platform (200kg/m² load capacity per level) |