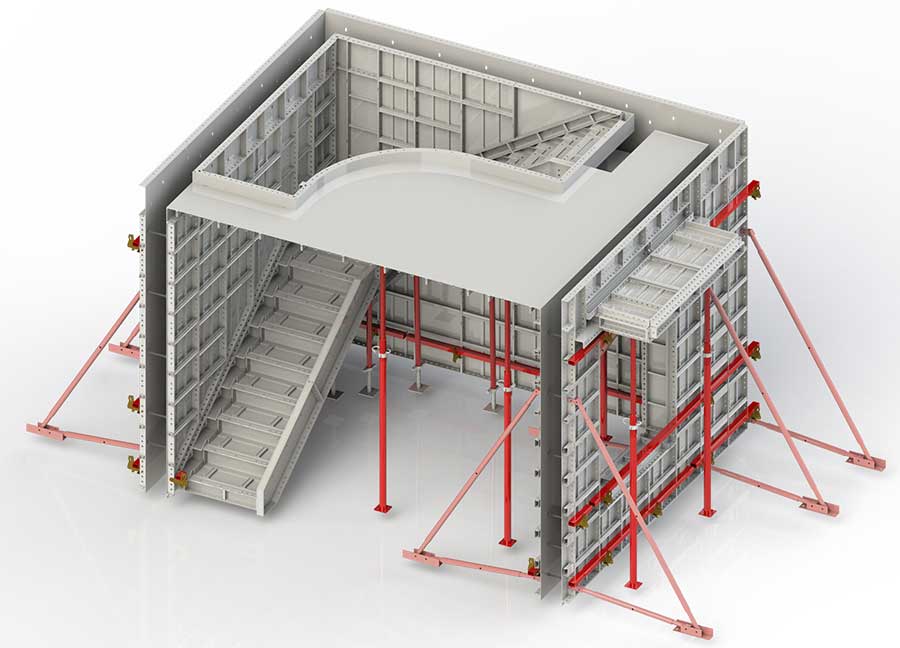

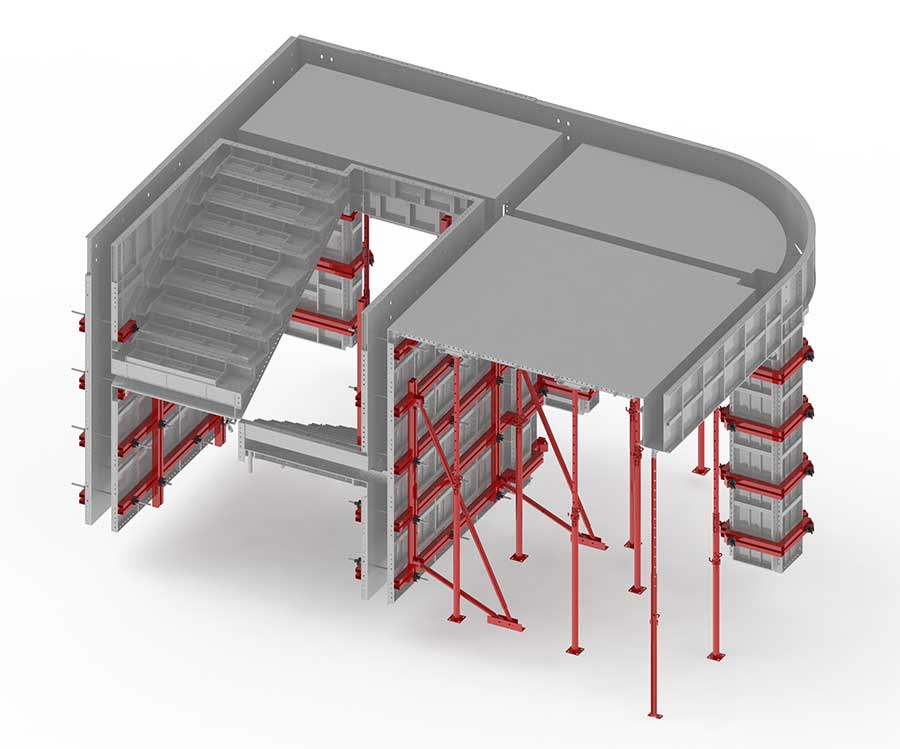

Aluminium formwork is mainly used to solve the formwork construction of the cast-in-place main structure of housing construction. It has the advantage of shortening the construction period and exempting the need for plastering on the structure. The use of aluminium formwork can complete the pouring construction of one floor in 3 to 5 days.

GETO aluminium formwork system is suitable for constructing typical floors, podiums and basement structures of residential construction projects such as high-rise residential apartments, office buildings, hotels, terrace houses, etc. It can also be used for part of the structure of public construction projects such as bridges, tunnels, pipe galleries, railways, etc.

The features of flat-tie system: The aluminium formwork reinforcement system of flat-tie type has lighter accessories in weight. It has smaller gaps for the distances between raking shores, which makes it more flexible for precision adjustments and more convenient for verticality control. Therefore, the casting result of the concrete wall using flat-tie reinforcement formwork system has better verticality. There are no obvious holes left in the concrete wall upon the dismantlement of the formwork system with embedded flat-ties, as the 2 edges of the flat-tie will be cut by using particular tools. Therefore, the cost for hole filling afterward can be saved up, while the waterproof construction quality for the wall body is more guaranteed.

| Materials for wall and column formworks with embedded flat-ties: | Materials for wall and column formworks with reusable flat-ties: |

| ▪ Embedded flat-ties ▪ Aluminium alloy wall panels with grooves at their edges ▪ Hookies ▪ Hollow sections ▪ Flat-tie raking shores ▪ Pins and wedges | ▪ Reusable flat-ties ▪ Flat-tie sleeves ▪ Aluminium alloy wall panels with grooves at their edges ▪ Hookies ▪ Hollow sections ▪ Flat-tie raking shores ▪ Pins and wedges |

| Materials for wall and column formwork using a tie-rod system: ▪ Tie-rods ▪ Aluminium alloy wall panels ▪ Walers ▪ Hexagonal nuts ▪ Gaskets ▪ Waler brackets ▪ Tie-rod raking shore |

The features of the tie-rod system: The main components of the tie-rod reinforcement system in aluminium formwork system are tension tie-rods, walers, and raking shores. The functions of these components are integrated to guarantee the strength, durability, and stability of the system. Upon the completion of the tension tie-rod and waler reinforcement, the stability of the overall wall body will become stronger. After the tie-rod formwork system is dismantled, many tie-rod holes will be left in the wall body, where special waterproofing measures should be done to the tie-rod hole positions.

▪ Large areas of single panels, less patchwork

▪ High precision

▪ High bearing capacity

▪ High concrete surface quality

▪ Workers can carry and assemble the formwork efficiently without any equipment due to the light weight

▪ The assembly is simple and flexible like building blocks

▪ The formwork has high strength, high bearing capacity, and is not easy to deform

▪ After the system is assembled, a whole frame is formed with high stability

▪ The service life of aluminium formwork can reach 200-300 times, the utilization is high

▪ The scrap aluminium formwork can be recycled, contributing to environmental protection

▪ Reduce the construction waste

Aluminum formwork system construction has a variety of series

suitable for a variety of fields:

▪ Typical floors, similar house type and others

▪ Apartments

▪ Office towers

▪ Terrace houses

▪ Hotels

▪ etc.

GETO offers one-stop package solutions for its product and service offerings. Products in GETO’s one-stop package include the podium formwork system, the basement formwork system, the typical floor formwork system, the roofing formwork system and the self-climbing platform.

Pre-sales service

We can offer pre-sale analytics and quote service.

During-sales service

We offer individualized service, drawing detailing, design and on-site engineering services, including technical briefing, technical training and on-site instruction to ensure on-site obstacles are cleared during use of the product.

We also provide refurbishment services for customer’s formwork system. By adopting GETO ERP Warehousing System, we simplify the recycling of customers’ existing panels and management process on-site. By refurbishment design, we maximize the turnover rate of the aluminium formwork system. With the improvement of the exiting panel turnover rate, the project cost will be minimized.

After-sales service

To enhance customer experience, our Customer Service Department will build and monitor customer data to track any issues that customers might face during use of the product.