In modern construction, Shoring Systems play a vital role in ensuring structural safety and stability during formwork, scaffolding, and shoring. Among the available options, aluminium beams have emerged as a superior solution due to their unique combination of lightweight design and high strength. This synergy enhances construction efficiency, reduces project costs, and promotes sustainable building practices.

Widely compatible with aluminium formwork, traditional formwork (timber or steel), and plastic formwork, aluminium beams provide versatility across diverse project types. This article highlights their core advantages, practical applications, and how GETO’s aluminium beams contribute to efficient, safe, and sustainable construction workflows.

Why Aluminium Beams Excel in Modern Construction

Lightweight Design

Aluminium has a density approximately one-third that of steel, making aluminium beams significantly lighter. This provides several strategic benefits:

- Lower Transport Costs: Reduced weight cuts fuel consumption during transportation, lowering both costs and emissions.

- Ease of Handling: Lightweight beams allow for manual movement by workers, especially valuable in confined or elevated job sites.

- Faster Installation: The reduced weight accelerates assembly and disassembly, crucial for projects with tight schedules.

In high-rise projects, where overall structural weight impacts foundation design and equipment demands, aluminium beams streamline logistics and improve site safety.

High Strength and Long-Term Durability

Despite their light weight, aluminium beams are remarkably strong. Engineered aluminium alloys offer high tensile strength and resistance to deformation, providing long-term structural reliability. Key advantages include:

- Corrosion Resistance: Naturally resistant to rust, aluminium performs well in humid and coastal environments without needing protective coatings like steel.

- Extended Lifespan: Durable under heavy loads and repeated use, aluminium beams reduce the need for frequent replacements, thereby cutting long-term costs.

This strength-to-weight ratio is ideal for demanding construction environments.

Modularity and Versatility

Thanks to their modular design, aluminium beams integrate seamlessly with multiple formwork systems. Standardized profiles allow for rapid assembly, while custom options (lengths, shapes, and connectors) can be tailored to project-specific requirements. GETO’s aluminium beams support a wide range of applications—from high-rises and tunnels to bridges and residential structures.

Sustainability: A Greener Choice

As sustainability becomes a global priority, aluminium beams offer eco-friendly advantages:

- High Recyclability: Nearly 100% recyclable, aluminium retains its properties through repeated use cycles.

- Reduced Resource Use: Their durability means fewer replacements, conserving raw materials and reducing waste.

- Lower Transport Emissions: Their lightweight design cuts down on shipping emissions.

Compared to timber (which contributes to deforestation) and steel (with high energy production costs), aluminium beams are a greener alternative that aligns with sustainable construction goals.

The Role of Aluminium Beams in Shoring Systems

Shoring Systems are designed to distribute loads safely during the construction process. Aluminium beams enhance these systems with strength, adaptability, and cost-effectiveness.

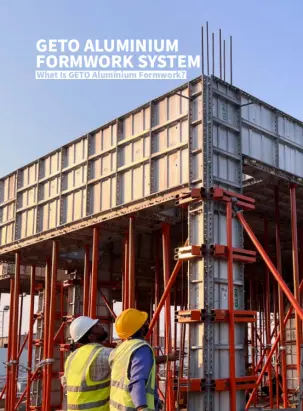

Aluminium Formwork Integration

In aluminium formwork systems, precision and speed are paramount. Aluminium beams provide critical structural support:

- Slab and Wall Construction: Beams offer the rigidity needed for wet concrete, ensuring accurate alignment and high-quality surface finishes.

- Operational Efficiency: With precise joints and standardized sizes, GETO’s aluminium beams reduce crane time and labor input, especially in high-rise or congested sites.

Their robust performance makes them indispensable in large-scale developments.

Compatibility with Traditional Formwork

Although aluminium is gaining popularity, timber and steel formwork still dominate in some regions. Aluminium beams improve these systems:

- With Timber Formwork: They enhance stability, compensating for timber’s lower strength.

- With Steel Formwork: They reduce the system’s overall weight, easing handling without compromising structural integrity.

This hybrid use is ideal for bridge construction and heavy civil infrastructure.

Synergy with Plastic Formwork

Plastic formwork is often used in repetitive or small-scale projects. However, its rigidity under load can be insufficient. Here, aluminium beams serve as reinforcements:

- Precast Applications: Beams support plastic molds during concrete curing, reducing deformation.

- Modular Production: Their low weight allows faster reconfiguration of molds, enhancing production efficiency.

This pairing excels in cost-driven, mass production settings.

Real-World Advantages: Lightweight Strength in Action

The balanced performance of aluminium beams, lightweight yet strong, offers unmatched benefits across varied construction environments.

High-Rise Construction

In vertical developments, minimizing weight is essential to limit load on foundations. The strength-to-weight ratio of aluminium beams supports taller buildings with slimmer foundations. Their easy handling reduces crane use, lowering costs and improving safety.

Complex Architectural Forms

For curved facades, cantilevered structures, or non-linear geometries, aluminium beams can be custom-fabricated to fit unique architectural needs, supporting both form and function.

Rapid Construction Projects

Time-sensitive construction benefits greatly from aluminium beams due to their ease of use and reusability. From modular housing to infrastructure projects, they accelerate timelines and reduce costs without compromising quality.

These field-proven advantages make GETO’s aluminium beams an optimal solution for builders seeking a balance between performance and practicality—without the need for complex or site-specific customizations.

Challenges and Solutions

Initial Investment

Aluminium beams may have a higher upfront cost compared to timber or plastic alternatives. However, their long lifespan and reduced labor needs offer strong return on investment.

Learning Curve

Construction crews may require training for optimal usage. Manufacturers like GETO provide technical guidance, manuals, and on-site support to ensure best practices.

Environmental Concerns

Although aluminium production can be energy-intensive, recycling aluminium requires only 5% of the energy used in primary production. Today, more manufacturers,including GETO, are investing in greener processes and renewable energy sources.

Future Trends: What’s Ahead for Aluminium Beams

The construction industry is embracing innovation, and aluminium beams are central to this shift:

- Advanced Manufacturing: CAD design and 3D printing are enabling custom profiles optimized for strength and weight.

- Smart Construction: Embedded IoT sensors in beams can monitor structural stress and load distribution in real-time.

- Sustainable Sourcing: The use of recycled aluminium and cleaner production technologies will further enhance environmental performance.

Conclusion

Aluminium beams are transforming the landscape of Shoring Systems in construction. By combining lightweight properties with impressive strength, they offer unmatched advantages for efficiency, safety, and sustainability. Whether integrated with aluminium, timber, or plastic formwork systems, GETO’s aluminium beams have proven themselves across a spectrum of applications—from high-rises to infrastructure and industrial facilities.

As the industry advances toward smarter and greener construction, aluminium beams will continue to play a leading role in delivering cost-effective, high-performance, and environmentally responsible building solutions.