Formwork Systems

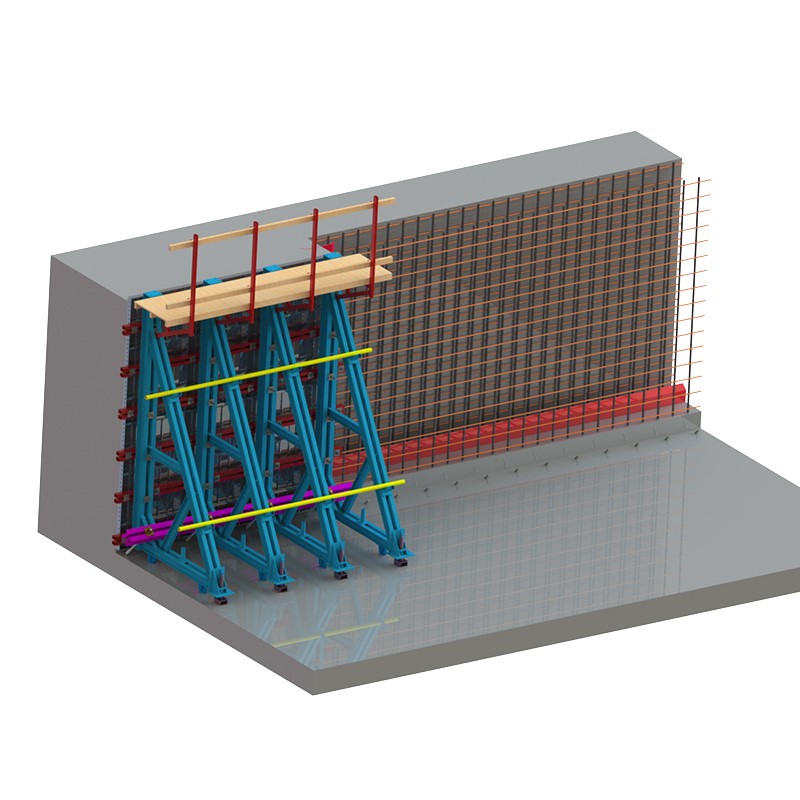

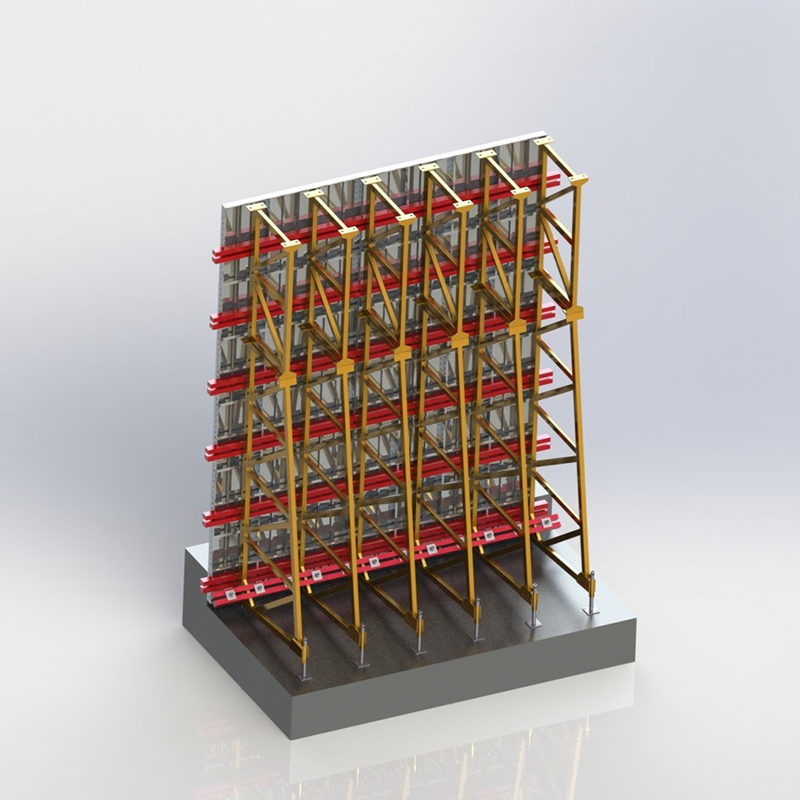

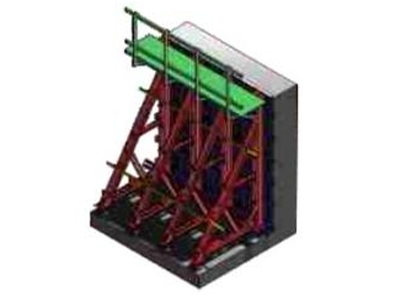

Heavyweight Triangular Truss Type Single-Side Wall Framework

Lightweight Triangular Truss Type Single-Side Wall Framework

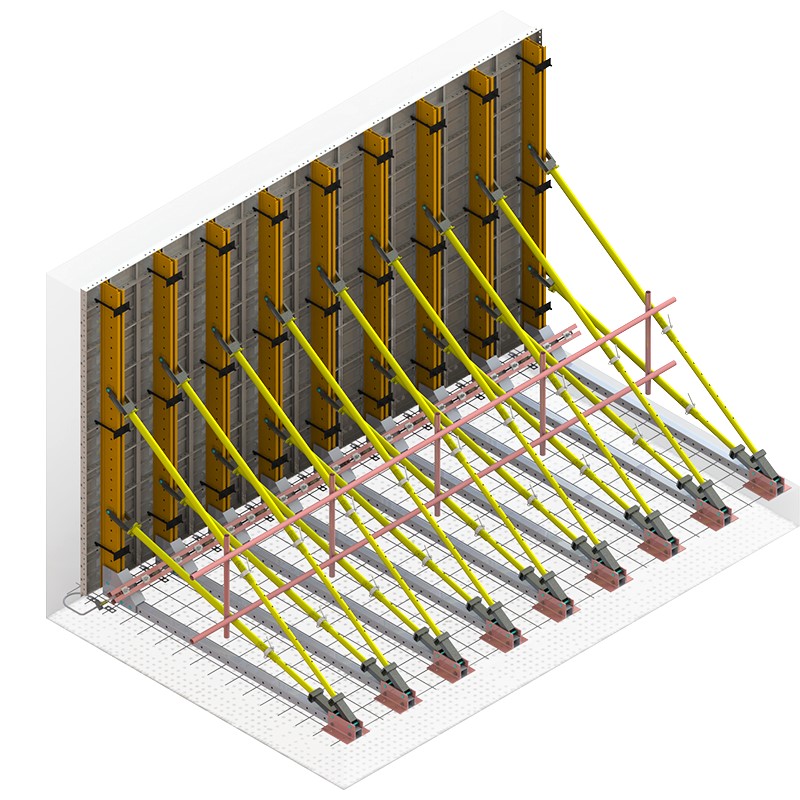

Aluminium Beam Type Single-Side Wall Framework

Specifcation

| Aluminium Beam Type Single-Side Wall Framework | Triangular Truss Type Single-Side Wall Framework | |

| Framework Pattern |  |

|

| Applicable Single-Side Wall Height | 3.0m and below | 3.0m-7.5m |

| Layout Spacing | 600mm | 800mm |

| Weight of Aluminium Components | 16.92kg | |

| Weight of Steel Components | 106.15kg | 208.37kg |

| Waler in Need | No | Yes |

| Total Weight of the Framework | 125.35kg | 208.37kg |

| Advantages | ①The framework has lighter weight.Its weight is only 60%of the weight of the triangular truss single-side famework, which can be manually moved or lifted; ②High reuse rate of material,with part of the product materials can be turned over to other construction sites for use; ③Lower material cost; ④Aluminium components has higher scrap values; ⑤Less labor works and safer operation; ⑥Compliant with environmental-friendly building requirements. |

①Overall framework is strong,with majority of the components welded in a factory; ②Less works for installation and dismantlement,contributing to higher working efficiency on site; ③Stable frame structure with better mechanical performance. |

Precautions for Single-Side Wall Framework Casting

- Control the casting speed to prevent bulging.

- It is suggested to cast by sections with leveraging, as to fix the framework position and improve the casting quality finished concrete casting product.

- It is suggested to cast by layers, as to assist the elimination of gas in concrete and reduce the occurrence of honeycomb phenomena on the concrete surface.

Installation

Casting Effect