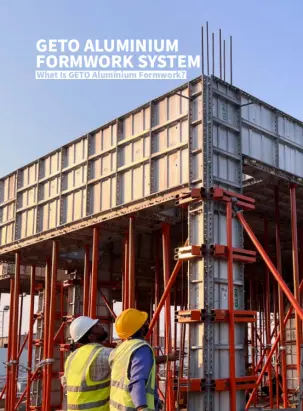

Aluminum formwork systems have seen broad use in construction due to their benefits over traditional timber and steel formwork. An aluminum system gives builders a functional solution, delivering precision, speed, safety, and sustainability on projects big and small. It enables fast, efficient building of walls, columns, and slabs through lightweight yet sturdy aluminum panels. This pioneering aluminium formwork system technology has massively boosted construction productivity globally.

Types of Aluminium Formwork Systems

There are two primary aluminium formwork system types used in building construction. Each caters to different project requirements by fulfilling the structural and functional needs of a wide variety of construction projects. The types include:

Flat-Tie System

This formwork system features internal connectors and flat ties to fix formwork panels together. It requires less accessories for assembly and provides higher precision. Without tie-rod holes, it achieves a smoother concrete surface finish.

Tie-Rod System

With external connectors and tie rods passing through the panels, the tie-rod aluminium formwork system delivers high strength and stability essential for renovation projects or structures with a wall thickness of over 400mm. Its versatility enables formwork refurbishment and repeated usage on multiple floors of high-rise buildings.

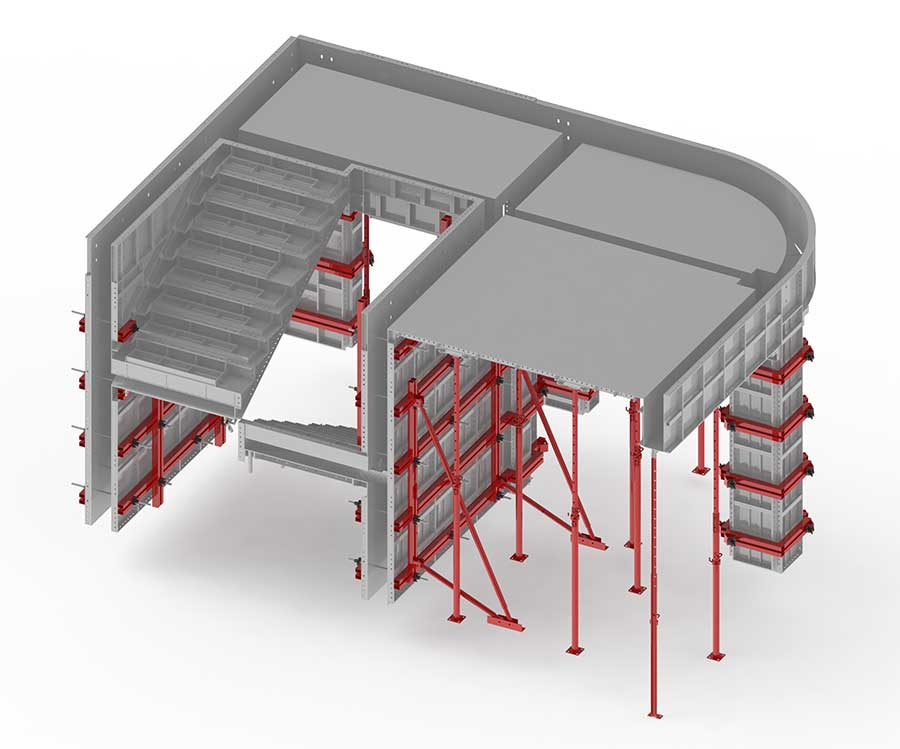

Major Components of Aluminium Formwork

Panels, connectors, and bracing elements are the core component categories of an aluminium formwork system. These components work together to enable smooth construction.

Panels

Panels act as the main load-bearing parts and come in various types to serve different purposes. Wall panels are the most commonly used and contain tie rod holes for the construction of walls. Wall top panels are utilized for the tops of walls. Column panels form the molds for column construction. Crane-way panels provide paths for cranes to travel on during high-rise building works.

Connectors

Connectors play a vital joining role. External joint connectors fix panels on the outside of structures. Internal joint connectors are used between adjacent panels from inside. Beam corner joints connect wall and beam panels at angled positions. The sturdy designs of these connectors guarantee panels are firmly interlocked and free of gaps or misalignment.

Bracing

Temporary bracing elements provide crucial stability to support beams, roofs, and more during construction. Kicker braces support the base of beams. Soffit braces are attached to slab undersides. Semi-circular rocker braces resist uneven loading on curved structures. The adjustable bracing connections conform to irregular profiles and deliver maximum safety even under high load conditions.

GETO Offers Comprehensive Formwork Solutions

The premier formwork company GETO has years of experience designing and manufacturing world-class aluminium formwork system solutions. We are committed to innovation and sustainability, with 10 production bases and large annual capacity. Our one-stop solutions include formwork, scaffolding, precast components, and more. Developing new products and solutions to maximize construction efficiency is the key strength that sets us apart from the competition.

At GETO, we provide comprehensive aluminium formwork system solutions and whole-chain services, including system design, formwork material provision, scaffolding solutions, equipment leasing, technical training, and maintenance support. Customers benefit from our:

- Tailored designs optimized for every project’s unique space constraints, load-bearing needs, and construction schedule.

- Lower overall costs through our optimization of construction workflows. Standardized systems facilitate swift assembly/dismantling and frequent re-use of common parts.

- Superior quality backed by rigorous sourcing of premium aluminum alloy and stringent manufacturing protocols.

- Dedicated after-sales teams providing dependable product maintenance and troubleshooting support.

Conclusion

Overall, aluminium formwork systems have evolved the construction process. The two primary types of aluminium formwork – flat-tie and tie-rod systems are suitable for different project requirements and constraints. Major components of aluminium formwork systems, such as panels, connectors, and bracing elements, all enable smooth construction.

As a leading global brand, GETO offers project-specific solutions through a wide choice of high-quality aluminium formwork and one-stop services. Our customers are assured of maximum efficiency and safety, as well as savings on their construction in Malaysia, Singapore, etc. Visit our website to learn more about our innovative offerings.

FAQ

What is an aluminium formwork system?

An aluminium formwork system is a construction technology using lightweight, durable aluminium panels to create molds for casting concrete structures like walls, columns, and slabs, offering precision, speed, and sustainability.

What are the benefits of using aluminium formwork over traditional formwork?

Aluminium formwork provides faster assembly, higher precision, smoother concrete finishes, reusability, and enhanced safety, reducing costs and environmental impact compared to timber or steel formwork.

What are the differences between flat-tie and tie-rod systems?

- Flat-Tie System: Uses internal connectors for a smoother finish without tie-rod holes, ideal for high-precision projects with fewer accessories.

- Tie-Rod System: Uses external connectors and tie rods for greater strength, suitable for thick walls or renovation projects, allowing refurbishment and reuse.

What are the key components of an aluminium formwork system?

The main components are:

- Panels: Wall, wall top, column, and crane-way panels for load-bearing and molding.

- Connectors: External, internal, and beam corner joints for secure panel connections.

- Bracing: Kicker, soffit, and rocker braces for stability under various loads.

How does GETO ensure the quality of its formwork systems?

GETO ensures quality through premium aluminium alloys, stringent manufacturing standards, tailored designs, and dedicated after-sales support for maintenance and troubleshooting.

What services does GETO offer with its aluminium formwork systems?

GETO provides system design, material provision, scaffolding, equipment leasing, technical training, and maintenance support, optimizing efficiency and safety for each project.

Can aluminium formwork systems be reused?

Yes, both flat-tie and tie-rod systems are designed for multiple uses, with GETO’s standardized components enabling easy assembly, dismantling, and refurbishment.

Where are GETO’s aluminium formwork systems used?

GETO’s systems are used globally, including in Malaysia and Singapore, for various projects, from small-scale to high-rise constructions.

How can I contact GETO for more information?

Visit GETO’s official website to explore our aluminium formwork solutions, scaffolding, and other construction services.