Amid the lush mountains of Malaysia's Genting Highlands, the Genting Highlands Major Infra Project (Genting Viaduct Project), supported by GETO New Materials, is progressing steadily. As a major road and bridge infrastructure project undertaken by GETO Group in the Malaysian market, it represents not only a key step in GETO's international strategy but also a clear demonstration of the company's expertise in high-end formwork systems and integrated engineering services.

Project Overview and Design Innovation | GETO's Contribution to the Genting Viaduct

The project is located in the Genting Highlands of Pahang, Malaysia. Spanning approximately 460 meters from end to end, the road-bridge section features a 50-meter elevation difference and an overall gradient of 10.858%, making it a representative example of high-elevation mountainous bridge construction. The route crosses three mountain ridges and four rivers, with steep terrain, complex topography, and rapidly changing weather, posing very high demands on design, construction planning, and safety management.

After multiple rounds of on-site investigation and design review, the project team found that some pile locations in the valleys could not support full falsework for cast-in-place construction, and the original plan posed schedule risks. After thorough evaluation, the team adopted a "new prefabrication yard + launching gantry beam erection" method, which effectively addressed the terrain constraints. To further reduce costs and improve efficiency, the bridge structure was systematically optimized—enhancing both its economic feasibility and constructability without compromising safety or quality.

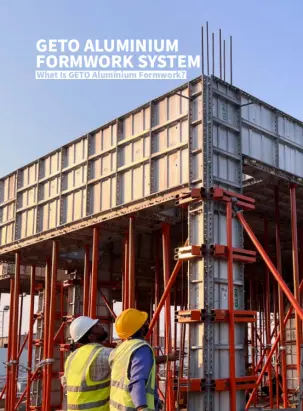

GETO provides professional contracting services for this project, covering roads, bridges, foundations, slope protection, drainage, and municipal facilities. In addition, the company supplies a complete formwork system and professional technical support for the viaduct's structural components, including steel formwork for pile caps, piers, tie beams, bent caps, T-beams,and truss platforms. Based on the site conditions, GETO's technical team customized the formwork design to ensure safety, precision, and efficiency throughout the construction process, while aligning closely with the project's overall contracting scope.

Overcoming Challenges | Tackling Complex Terrain and Harsh Conditions

The project team encountered multiple challenges throughout construction:

1. Difficult construction logistics.

Located on private land within the Genting area, the project faced restrictions on machinery and material transport, limited local labor availability, and high costs. Through active coordination and communication, the team secured a qualified construction workforce to ensure smooth project delivery.

2. Challenging topographic surveying.

The project site lies within dense tropical forest with limited access. Surveyors had to cut through vegetation by hand to open paths and identify control points, laying the groundwork for subsequent phases.

Early-Stage Project Construction Site

Pile Foundation and Beam Yard Construction Site

3. Complex technical execution.

During the construction of the temporary access road, frequent landslides and unstable geology required multiple route adjustments. The team eventually finalized the fourth route alignment, involving 50,000 cubic meters of earthfill and twin concrete culverts for drainage. During pile foundation works, they overcame high terrain elevation differences and narrow platforms by first building stable working platforms to ensure precise pile positioning.

In the precast beam yard construction, site space was limited. Through repeated coordination with the client, the team optimized the yard layout, balancing construction efficiency with environmental safety. Measures such as shotcrete slope protection, stepwise backfilling, and geogrid reinforcement ensured slope stability and foundation safety.

Green Construction and Environmental Protection | Building a Sustainable Highland Bridge

The Genting region's tropical rainforest climate brings long rainy seasons and frequent downpours, posing major risks to construction activities. To manage this, the team established sedimentation ponds and temporary drainage systems in advance. Slope protection measures such as shotcrete, turfing, and geotextile covering were implemented, with exposed soil promptly covered before heavy rains to safeguard both construction safety and the surrounding ecosystem.

As Genting is a protected natural area, strict environmental supervision is enforced. Construction wastewater cannot be discharged into municipal pipelines. To comply, the project team developed a comprehensive environmental management plan, including water quality monitoring and periodic cleaning of sedimentation ponds, ensuring full compliance with local environmental standards.

Commitment to Quality | Building Excellence through Professionalism

The successful progress of the Genting Viaduct Project demonstrates GETO New Materials' comprehensive strength in advanced formwork systems, integrated engineering solutions, and professional contracting services.

With a spirit of technical precision and rigorous project management, the GETO team continues to ensure the project's safe, efficient, and high-quality advancement—turning challenges in the highlands into milestones of achievement.

With strong financial backing, international vision, and decades of industry experience, GETO New Materials has built a trusted foundation for global cooperation. The company operates 12 production bases, holds GETO® trademarks in 32 countries and regions, and serves clients in over 70 global markets. GETO maintains the highest standards for every project, delivering premium-quality products and services that embody the "1+N" comprehensive green building solution—empowering clients worldwide to create sustainable value.