At a high-rise residential project in East Asia, GETO New Materials' Lifting Climbing Formwork System and aluminium formwork system have been successfully applied, providing an efficient, safe, and cost-effective solution for construction under complex structural conditions.

The project's external walls feature multiple window openings, curved wall sections, and cantilever slabs, creating challenges for conventional formwork systems that require both precision and flexibility. To address these conditions, the GETO engineering team provided a customized lifting climbing formwork solution, ensuring both construction efficiency and cost control while maintaining high safety and quality standards.

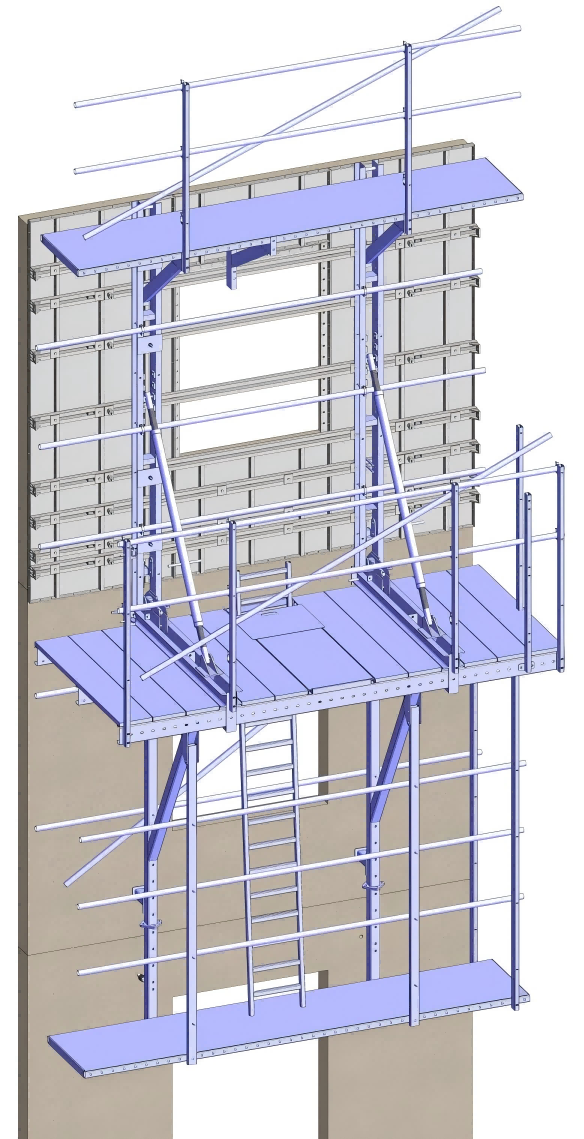

The Lifting Climbing Formwork System is a crane-lifted external formwork solution that allows the formwork and working platform to climb simultaneously. This system simplifies operation, shortens construction cycles, and reduces labor intensity. It is applicable to the construction of concrete structures such as building external walls, elevator shafts, bridge piers, anchorages, nuclear power plant containment shells, dams, and concrete retaining walls, providing formwork, support, and a working platform for vertical concrete placement.

Advantages:

①The brackets, formwork, and construction loads are all supported by tie rods, embedded parts, and load-bearing tripods, eliminating the need for additional scaffolding and making it suitable for high-altitude operations.

②The formwork can be anchored tightly to the concrete through the anchoring device, effectively preventing slurry leakage and misalignment.

For this project, GETO engineers optimized the system design in several aspects:

①To improve material reusability across different floor heights, the system adopts a modular design concept combining standard sections and extension units, equipped with an adjustable jack assembly that allows flexible support arrangements unaffected by window openings or cantilever slabs.

②For the curved facade areas, specially designed curved wall brackets ensure stable and safe operation of the climbing system during construction.

③The system incorporates the Spartite system, an upgraded flat tie system that maintains excellent waterproof performance while enabling integrated demolding operations, enhancing both concrete forming quality and construction efficiency.

The successful implementation of this project highlights GETO's strong technical capability and extensive experience in formwork and climbing systems for high-rise and complex structures. The enhanced lifting climbing formwork system effectively resolves the challenges of irregular geometries and high-precision requirements, supporting the contractor in achieving safe, efficient, and economical construction.

With strong financial backing, international vision, and decades of industry experience, GETO New Materials has built a trusted foundation for global cooperation. The company operates 12 production bases, holds GETO® trademarks in 32 countries and regions, and serves clients in over 70 global markets. GETO maintains the highest standards for every project, delivering premium-quality products and services that embody the "1+N" comprehensive green building solution—empowering clients worldwide to create sustainable value.