In the construction industry, time is money, and precision is everything. As we step into 2025, aluminium formwork systems are rapidly redefining the standards of efficiency on job sites worldwide. Compared to traditional wooden formwork, aluminium systems are lighter, more durable, and significantly faster to assemble, making them the preferred choice for high-rise buildings and large-scale developments.

But here’s the real question: among so many manufacturers, who truly stands out with the innovation, production capacity, and global support to lead the industry?

In this article, we reveal the Top Aluminium Formwork System Manufacturer of 2025, diving deep into their product innovation, manufacturing strength, export capabilities, and customer service—so you can make a smart, confident choice in a competitive market.

2025 Top-Rated Aluminium Formwork System Manufacturer

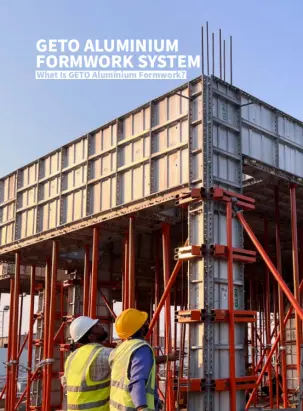

Geto Global Construction Tech

Aluminium Formwork System Manufacturer

Company Overview

Founded in 2011 and headquartered in Fuzhou City, Jiangxi Province, Geto Aluminium Formwork (Jiangxi GETO New Materials Corporation Limited) has rapidly risen to become one of the world’s leading manufacturers in the aluminium formwork system industry. Listed on the ChiNext board of the Shenzhen Stock Exchange in 2021 (Stock Code: SZ 300986), GETO stands out for its strong innovation, global reach, and unwavering commitment to sustainable construction.

Top Aluminium Formwork System Manufacturer in China

Core Strengths of GETO Formwork

GETO Formwork stands out as a trusted global partner in the construction industry, thanks to its expertise in aluminium formwork systems, advanced manufacturing, and smart technologies. Its key strengths include:

✅ Specialized Aluminium Formwork Solutions

High-strength, lightweight, and reusable over 200 times—significantly reducing labor and project timelines.

✅ Strong Global Manufacturing Network

12 production bases across the world, serving over 60 countries with fast response and reliable delivery.

✅ Comprehensive Building System Provider

Offers not only formwork, but also climbing systems, shoring, modular buildings, and green energy solutions.

✅ Leading Digitalization and Smart Manufacturing

Proprietary BIM software and VR inspection tools boost accuracy, efficiency, and on-site quality control.

✅ Pioneer in Green and Low-Carbon Construction

All systems are recyclable and eco-friendly, promoting sustainable and energy-efficient building practices.

✅ Proven International Project Experience

Successfully implemented in Asia, the Middle East, Africa, Latin America, and beyond.

✅ Tailored Solutions and Technical Support

Dedicated design teams, on-site assistance, and 24/7 overseas customer service ensure project success.

One of the Best Aluminium Formwork System Manufacturers

Global Trends and Market Analysis of the Formwork System Industry

The formwork industry is an indispensable supporting sector in construction, primarily providing temporary support structures for shaping concrete or precast components. With accelerating urbanization, increased infrastructure development, and growing demand for efficient and sustainable construction worldwide, the formwork market is experiencing rapid growth. Major materials include aluminum, steel, wood, and plastics, with regional preferences influenced by local resources and project requirements.

Global Market Size and Growth Drivers

In recent years, the global formwork market has maintained steady growth. Key factors driving expansion include rapid urbanization in Asia, Africa, and the Middle East, increased investments in infrastructure modernization, and the rising demand for green and energy-efficient construction techniques. Aluminum formwork is favored in many repeat-use construction projects for its lightweight, durability, and high reuse count. Composite plastic formworks and other eco-friendly materials are gaining traction, especially in developed countries.

Industry Chain Structure and Regional Resource Advantages

The formwork industry typically features a three-tier supply chain: upstream, midstream, and downstream. The upstream segment supplies raw materials such as aluminum extrusion, steel, wood, and plastic. China, as the world’s largest aluminum extrusion producer, provides critical raw material support. The midstream focuses on design, manufacturing, and leasing of formworks, where leading companies leverage intelligent and digital technologies like BIM to improve design efficiency and accuracy. The downstream segment involves actual application, where formworks are extensively used in residential, infrastructure, and public facilities construction, closely linking suppliers and contractors to reduce costs and shorten construction timelines.

Green and Sustainable Development Trends

The industry is witnessing significant trends toward green and sustainable development. Environmental regulations and green building standards globally are pushing the formwork materials towards recyclable and low-carbon solutions. Aluminum and composite plastic formworks are increasingly adopted for their environmental advantages.

Integration of Smart and Digital Technologies

Digitalization and smart construction technologies are being integrated into formwork design and management. Technologies such as BIM, the Internet of Things (IoT), and virtual reality (VR) enable precise design and real-time site monitoring, enhancing construction efficiency and management.

Prefabricated Construction Driving Formwork Innovation

With the rise of prefabricated and modular construction, formwork technology has become more critical. Formworks support high-quality off-site prefabrication and ensure fast and accurate on-site assembly, significantly reducing construction durations.

Regional Market Characteristics and Differentiated Demand

There are distinct regional differences in the formwork market. Developed countries emphasize eco-friendly and automated technologies, while developing regions prioritize cost-effectiveness and scale, resulting in diverse regional market landscapes.

Competitive Landscape and Technology-Driven Innovation

The global formwork industry is highly competitive and fragmented, with numerous companies striving to enhance market position through continuous technological innovation and global expansion. Green materials and digital transformation remain the key competitive focuses.

New Materials Driving Industry Innovation

Emerging lightweight, high-strength materials such as magnesium alloys and carbon fiber composites are gradually entering the market, pushing the industry toward greater efficiency and environmental friendliness.

Policy Support and Industry Standardization Promoting Growth

Government policies and industry standards contribute to healthy and orderly development, ensuring fair competition and unified technical benchmarks.

Industry Outlook

Looking ahead, as urbanization continues and green building principles deepen, the formwork industry is set for sustained growth. The application of new materials and intelligent systems will further enhance formwork performance and construction efficiency. Overall, the global formwork industry will move towards a new stage characterized by technology-driven innovation, environmental sustainability, and regional customization to meet the increasingly complex and diverse needs of modern construction.

Top Aluminium Formwork Manufacturers

What is the price trend of aluminum formwork in China in 2025?

Factors affecting prices include:

Significant Price Surge in Building Formwork Systems in 2025

As 2025 unfolds, the prices of building formwork systems in China have seen a notable upward trend. Taking the commonly used wooden formwork as an example, its price has increased sharply compared to previous years—rising from around RMB 50 per square meter to RMB 80, marking a 60% increase. Aluminum formwork has followed a similar trajectory, with prices climbing from RMB 300 to RMB 450 per square meter, a 50% jump. These price hikes are not coincidental; they are driven by a complex mix of factors.

Rising Raw Material and Production Costs Drive Prices Higher

One of the primary drivers behind the price increase is the rising cost of raw materials. Due to tightened forest protection policies in China, timber harvesting has become more restricted, leading to reduced supply and higher prices. Meanwhile, aluminum, a crucial industrial material, has been subject to global commodity price fluctuations, resulting in a generally upward pricing trend.

At the same time, increasingly stringent environmental regulations are compelling formwork manufacturers to invest heavily in eco-friendly production equipment and technology upgrades to reduce emissions. These investments significantly raise production costs. Furthermore, a growing shortage of skilled construction labor has led to continuous wage increases, further fueling the rise in formwork prices.

Technological Advancements Drive Industry Transformation

Recent developments in the industry reflect a rapid shift toward innovation. On April 16, 2025, China Railway Construction Engineering Group filed a patent for a "lightweight high-strength building formwork and its preparation method." This new design leverages unique structural engineering and advanced manufacturing techniques to produce formwork that is both lighter and stronger, improving construction efficiency.

Similarly, on May 2, 2025, Hebei Guangxin Aluminum Formwork Technology Co., Ltd. obtained a patent for a “modular aluminum alloy formwork.” This innovation features an optimized connection mechanism that significantly reduces the time needed for alignment and positioning during installation, greatly enhancing productivity. These technological breakthroughs underscore the industry's commitment to research and development.

Promising Market Outlook and Accelerated Adoption of New Formwork Solutions

The market outlook for the building formwork industry remains strong. With China's economy maintaining steady growth and urbanization accelerating, demand for formwork systems in infrastructure development, real estate, and industrial construction continues to rise. The advancement of new urbanization projects has raised the bar for quality and performance, pushing the industry toward more sophisticated and efficient solutions.

Green building practices are also becoming more mainstream, fueling demand for environmentally friendly formwork systems. New materials such as aluminum and steel formworks are gaining traction due to their lightweight, durable, and recyclable properties. In fact, aluminum formwork production in China reached 1 million tons in 2024, representing a 20% year-on-year increase, signaling strong momentum for future growth.

| Formwork Type | Avg. Price in 2024 (RMB/㎡) | Avg. Price in 2025 (RMB/㎡) | Increase Rate | Remarks |

|---|---|---|---|---|

| Wooden Formwork (Basic) | ~50 RMB | ~80 RMB | ↑ 60% | Price surge due to timber shortage and stricter environmental policies |

| Aluminium Formwork | ~300 RMB | ~450 RMB | ↑ 50% | Driven by rising aluminum prices, environmental costs, and labor wages |

| Steel Formwork | ~250 RMB | ~330 RMB | ↑ 32% | Durable but heavy; higher transport and labor costs |

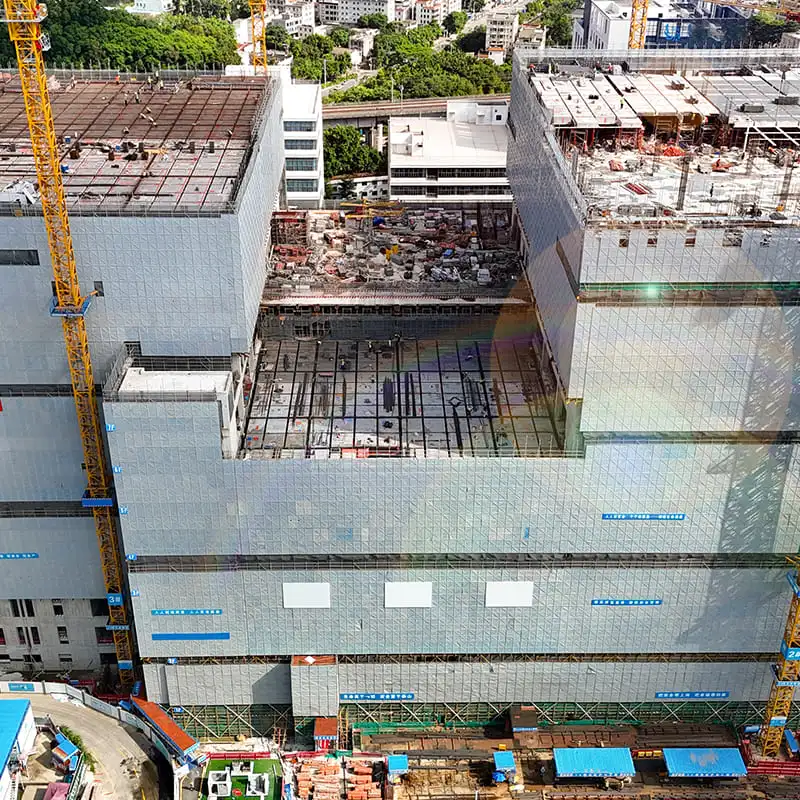

One of The Best Aluminium Formwork Manufacturers In The World

Aluminium Formwork System Manufacturers with a Strategic Vision - GETO

In an industry full of opportunities and challenges, Geto Green Building Technology has consistently demonstrated outstanding performance and solid strength. Headquartered in Jiangsu, China, Geto is a national high-tech enterprise specializing in the research, production, and service of aluminum formwork and climbing platform systems. With a modern production base of nearly 200,000 square meters and multiple fully automated intelligent production lines, Geto ranks among the industry leaders in annual output, ensuring efficient delivery and a stable supply of high-quality products.

On the technological front, Geto is committed to independent innovation and has obtained over 100 patents. Backed by a team of senior engineers and industry experts, the company continuously drives product upgrades and process improvements. Its signature aluminum formwork systems are not only lightweight, strong, and environmentally friendly, but also highly reusable, efficient in construction, and easy to assemble and disassemble. These products have been widely applied in numerous major projects at home and abroad, including residential developments in Xiong’an New Area and high-rise housing in Kuala Lumpur, Malaysia, earning widespread recognition from clients.

Looking ahead, Geto will continue to integrate intelligent manufacturing with green building concepts, expand its global market presence, and further enhance its brand influence and competitive edge. The company is dedicated to becoming a global leader in industrialized construction, making greater contributions to the sustainable development of the building industry.

How to Choose the Right Aluminium Formwork System Manufacturers?

Choosing the right aluminium formwork system manufacturer involves evaluating multiple key aspects to ensure both quality and long-term value. Here are the main factors to consider:

Technical Expertise & R&D Capabilities

Ensure the manufacturer has a strong technical team and active research and development capabilities to provide innovative, efficient, and reliable solutions.

Production Capacity

Look into their factory scale, equipment, and annual output. High production capacity often correlates with better delivery timelines and consistent product quality.

Reputation & Project Portfolio

A manufacturer with a proven track record, industry certifications, and experience in well-known construction projects is more likely to be trustworthy and competent.

Product Variety & Quality

Check whether the manufacturer offers a wide range of formwork types with high standards of strength, precision, and reusability.

After-Sales Support

Strong technical support, on-site guidance, and fast response to issues are critical for smooth project execution.

Cost-Effectiveness

While price matters, the lowest cost doesn’t always equal the best value. Evaluate the long-term performance and service benefits of the product.

Sustainability & Environmental Commitment

Manufacturers who use eco-friendly materials and production processes align better with today’s green building trends.

Factory Visit & Transparency

If possible, arrange an in-person or virtual factory tour. This helps verify the manufacturer’s capabilities and professionalism firsthand.