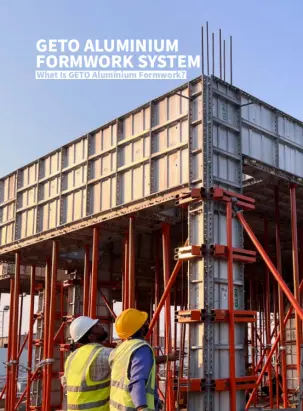

In modern construction, particularly for structures like subway stations and basement external walls, achieving high waterproofing standards is critical. Traditional construction methods often rely on tie-rod systems for formwork reinforcement, but these are unsuitable for projects where waterproofing is paramount, as tie-rods can create potential leakage points. To address this, single-side wall framework systems have emerged as a specialized solution for casting concrete structures where only one side of the formwork can be supported. This article explores two primary types of single-side wall framework systems—Triangular Truss Type and Aluminum Beam Type—as developed by GETO, focusing on their design, installation, operational methods, and advantages.

Overview of Single-Side Wall Framework Systems

Single-side wall framework systems are designed for casting building structures with stringent waterproofing requirements, such as railway stations and basement external walls, where tie-rod systems are impractical. These systems allow concrete to be poured against a single-sided formwork, supported by robust frameworks that withstand the pressure of wet concrete without compromising structural integrity or waterproofing. These systems are suitable for structures with a casting height of up to 7.5 meters.

Key Features

- Purpose: Catered to structures where tie-rods cannot be used due to waterproofing demands.

- Applications: Ideal for subway stations, basement external walls, and similar structures.

- Height Limitation: Applicable for casting heights ≤ 7.5 meters.

- Types: Two primary configurations exist,Triangular Truss Type and Aluminum Beam Type, each with distinct construction and operational methodologies.

Triangular Truss Type Single-Side Wall Framework

The Triangular Truss Type Single-Side Wall Framework is a conventional approach that leverages a robust, triangular truss structure to support the formwork. This system is versatile, allowing for various methods of movement and turnover based on site conditions and available machinery.

Characteristics

- Mobility: The framework can be moved and turned over using multiple methods, including:

- Tower Crane: For lifting and positioning the truss framework.

- Mobile Crane: Suitable for sites with access to mobile lifting equipment.

- Manpower Push: Manual movement for smaller-scale operations or constrained sites.

- Truck Moving: For efficient transport across larger construction sites.

- Applicability: The choice of movement method depends on the machinery available and site-specific conditions, ensuring flexibility in diverse construction environments.

Installation Flow

The installation process for the Triangular Truss Type framework involves the following steps:

- Cast the Base Plate: Pour the foundation base plate to provide a stable platform for the framework.

- Fix Waler at Designed Height: Use L-type mobile tie-rods to secure the waler (horizontal support beam) at the predetermined height, ensuring alignment with the design specifications.

- Hoist and Connect Triangular Truss: Lift the triangular truss into position using a crane and connect it to the horizontal waler using a connecting rod. This ensures the truss provides adequate support against the concrete pressure.

Operational Considerations

- Casting Speed Control: To prevent bulging of the formwork, the concrete pouring speed must be carefully controlled.

- Layered and Symmetrical Casting: GETO recommends casting in layers and symmetrically to maintain formwork stability and enhance the quality of the concrete finish. This approach helps fix the position of the framework and minimizes displacement during pouring.

- Gas Elimination: Layered casting facilitates the release of trapped gases in concrete, reducing the likelihood of surface imperfections such as honeycombing.

Aluminum Beam Type Single-Side Wall Framework

Recognizing the need for a more lightweight and efficient solution, GETO developed the Aluminum Beam Type Single-Side Wall Framework. This system aligns with modern construction demands for high turnover rates, operational convenience, and compliance with green building trends.

Development and Design

GETO’s development of the Aluminum Beam Type framework involved:

- Market Analysis: Thorough research into market dynamics and customer preferences.

- Cost Consideration: Balancing comprehensive costs, including materials and labor.

- Turnover Rate: Designing for high reusability to maximize efficiency.

- Operational Convenience: Simplifying installation and dismantlement processes.

- Application Versatility: Ensuring adaptability to various construction scenarios.

The result is a lightweight system that reduces material weight while maintaining structural integrity, making it easier to handle and more environmentally sustainable.

Installation Flow

The installation process for the Aluminum Beam Type framework includes the following steps:

- Cast the Base Plate and Embed Anchor Bolts: Pour the foundation base plate and embed anchor bolts at designated positions to secure the framework.

- Install Wall Panel and Aluminum Beam: Apply a mold release agent to the wall panel before installation to facilitate later removal. Temporarily fix the framework with steel pipes during setup to ensure stability.

- Install Connecting Components and Base Horizontal Beam: Attach connectors between the main beam and horizontal beam, followed by the installation of the base horizontal beam.

- Install Horizontal Beam and Corner Steel Base: Secure the horizontal beam and attach the corner steel base to the base horizontal beam for additional support.

- Install Single Props and Horizontal Rods: Add single props and horizontal rods to reinforce the framework against concrete pressure.

- Adjust and Cast Concrete: Adjust the framework to ensure straightness, verify the tightness of embedded components, and proceed with concrete pouring.

Dismantlement Flow

The dismantlement process is equally systematic to ensure efficiency and safety:

- Prepare Tools: Gather necessary tools, including a hammer, hook, crowbar, spanner, and construction drawings, to facilitate dismantlement.

- Dismantle After Concrete Curing: Wait at least 24 hours after concrete pouring, ensuring the concrete strength reaches over 50%. Begin by removing horizontal rods, loosening single props, the corner steel base of the horizontal beam, and finally, the embedded parts.

- Remove Connecting Bolts and Pins: Dismantle the connecting bolts and pins of each component, organizing them according to their classification code for reuse.

- Dismantle Wall Panels and Transfer Materials: Remove the wall panels and transfer materials according to specific solution plans tailored to the site.

- Concrete Maintenance: After dismantlement, apply a curing agent to the concrete promptly. During winter construction, ensure proper insulation to prevent cracks that could lead to water leakage.

Operational Considerations

Similar to the Triangular Truss Type, the Aluminum Beam Type framework requires careful control of casting speed and layered, symmetrical pouring to prevent bulging and ensure high-quality concrete surfaces. The lightweight nature of the aluminum beams enhances ease of handling, reducing labor requirements and improving turnover rates.

Comparative Analysis

Both the Triangular Truss Type and Aluminum Beam Type single-side wall frameworks serve the same purpose, supporting single-sided formwork for high-waterproofing structures, but they differ in design and application:

- Weight and Material: The Triangular Truss Type relies on heavier steel components, making it robust but less portable. The Aluminum Beam Type uses lightweight aluminum, improving maneuverability and reducing environmental impact.

- Mobility: The Triangular Truss Type offers multiple movement options (tower crane, mobile crane, manpower push, truck moving), providing flexibility for various site conditions. The Aluminum Beam Type, while not explicitly detailed for mobility, benefits from its lighter weight, which simplifies handling.

- Installation Complexity: The Aluminum Beam Type has a more detailed and structured installation process, reflecting its design for operational convenience. The Triangular Truss Type has a simpler process but requires heavy lifting equipment for positioning.

- Sustainability: The Aluminum Beam Type aligns with green building trends due to its lightweight design and high turnover rate, reducing material waste and energy consumption.

Practical Applications

Both systems are designed for structures with casting heights up to 7.5 meters, making them suitable for:

- Subway Stations: Where underground conditions and waterproofing are critical.

- Basement External Walls: Requiring robust formwork to prevent water ingress.

- Other High-Waterproofing Structures: Such as tunnels or retaining walls where tie-rods are impractical.

The choice between the two systems depends on project-specific factors, including site access, available equipment, budget constraints, and environmental considerations.

Advantages of Single-Side Wall Framework Systems

- Enhanced Waterproofing: By eliminating tie-rods, these systems prevent potential leakage points, ensuring the integrity of waterproof structures.

- Versatility: Both systems accommodate various construction scenarios, with the Triangular Truss Type offering flexible mobility options and the Aluminum Beam Type prioritizing lightweight design.

- High Turnover Rate: The Aluminum Beam Type, in particular, is designed for frequent reuse, reducing costs and material waste.

- Operational Efficiency: Streamlined installation and dismantlement processes minimize labor and time requirements.

- Quality Control: Layered and symmetrical casting techniques improve concrete finish quality, reducing surface defects like honeycombing.

Challenges and Considerations

While single-side wall framework systems offer significant advantages, they also present challenges:

- Casting Speed Control: Improper pouring speed can lead to formwork bulging, requiring careful monitoring.

- Concrete Curing: Post-dismantlement maintenance, especially in winter, is critical to prevent cracks and ensure waterproofing.

- Equipment Dependency: The Triangular Truss Type often requires cranes, which may not be available on all sites.

- Initial Setup Complexity: The Aluminum Beam Type’s detailed installation process may require skilled labor to ensure precision.

Conclusion

Single-side wall framework systems, as exemplified by GETO’s Triangular Truss Type and Aluminum Beam Type, represent a significant advancement in construction technology for high-waterproofing structures. The Triangular Truss Type offers robustness and flexibility in movement, making it suitable for diverse site conditions. In contrast, the Aluminum Beam Type prioritizes lightweight design, operational convenience, and alignment with green building trends. Both systems adhere to strict waterproofing requirements, supporting casting heights up to 7.5 meters and ensuring high-quality concrete finishes through controlled pouring techniques. By addressing the challenges of traditional tie-rod systems, these frameworks provide efficient, sustainable, and reliable solutions for modern construction projects.