Prefabricated Prefinished Volumetric Construction (PPVC) is transforming the way buildings are designed, fabricated, and assembled. By taking an entire room of a building as a single module, PPVC enables construction projects to move faster, safer, and more efficiently. From high-rise apartments to public housing, this construction method is becoming an essential solution for modern building projects worldwide.

What is PPVC: Take A Closer Look

PPVC stands for Prefabricated Prefinished Volumetric Construction, a method where building modules—typically entire rooms—are prefabricated off-site in controlled factory environments and then transported to the construction site for assembly. Unlike traditional construction methods, which require extensive on-site labor and coordination, the PPVC construction system streamlines the construction process, delivering higher-quality results in less time.

Traditional vs. PPVC Molds Construction

Traditional building methods are labor-intensive and fragmented. Structural, architectural, and mechanical finishes are mostly executed on-site, resulting in complicated workflows, higher labor costs, and variable quality control. On-site construction is also susceptible to weather conditions, which can delay projects and reduce efficiency.

In contrast, the PPVC Molds centralizes production in a factory. Modules are fabricated under controlled conditions using standardized procedures. This not only enhances quality and consistency but also minimizes human error. Moreover, because most of the work occurs off-site, on-site construction becomes a straightforward assembly process, drastically reducing construction time and labor requirements.

Prefabricated Prefinished Volumetric Construction (PPVC)

Key Features of PPVC Molds

Prefabricated Room Modules: Every room, including walls, floor slabs, ceilings, door openings, and window frames, can be prefabricated as a single unit. This means modules are cast and molded in the factory, transported to the site, and assembled like building blocks.

Improved Efficiency and Safety: PPVC modules are prefinished in a controlled environment, reducing on-site activities such as scaffolding, cutting, and painting. This decreases dust, noise, and manual labor, creating a safer and cleaner construction site.

High-Quality Finish: The prefabricated modules achieve precise dimensions and a smooth finish, often delivering fair-faced concrete without the need for additional plastering. Automated and mechanical demolding ensures consistency and reduces the risk of errors like water leakage.

Weather-Resistant Construction: Because most fabrication occurs indoors, weather delays are minimized. Construction schedules become more predictable, and material performance is less affected by environmental fluctuations.

Environmentally Friendly: PPVC construction system supports green construction practices by reducing material wastage, minimizing on-site energy consumption, and aligning with global low-carbon building initiatives.

Product Solutions of PPVC Molds

Formwork systems are essential in the PPVC production process as they define the shape and structure of the prefabricated modules. There are several types of formwork systems used in PPVC construction:

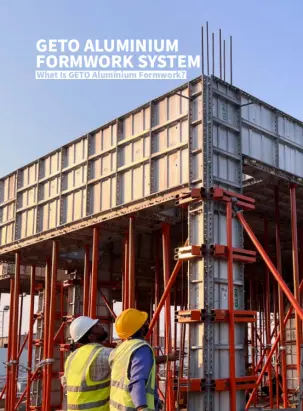

- Aluminium Formwork System: Aluminium molds are lightweight, easy to assemble and disassemble without cranes, and offer a short lead period. They are also recyclable, providing an additional environmental benefit.

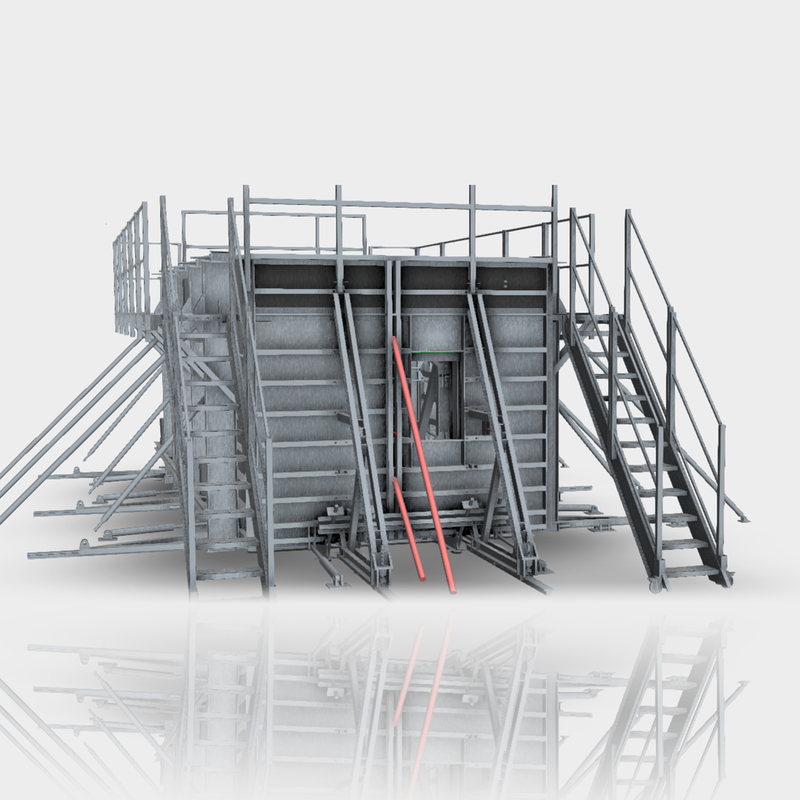

- Automatic Formwork System: These molds reduce labor costs and increase construction efficiency. Their adaptability makes them suitable for various PPVC structures, including complex high-rise projects.

- Non-Automatic Formwork System: Less expensive and easier to design, non-automatic steel molds leverage mature technology for reliable performance, though they require more manual labor.

PPVC Precast Housing Molds

GETO PPVC Precast Housing Molds: Build Faster, Smarter, Stronger

PPVC precast housing molds are at the heart of prefabricated volumetric construction. They allow the creation of fully formed building modules, including floors, walls, ceilings, and openings, in a single casting process.

Benefits of Using PPVC Precast Housing Molds

GETO PPVC precast housing molds offer a wide range of benefits that make them an efficient, reliable, and sustainable solution for modern construction projects:

Faster Construction: Entire room modules are prefabricated off-site, significantly reducing on-site construction time. This method can increase construction efficiency by up to 50% compared to traditional steel formwork. Faster assembly accelerates project delivery without compromising quality.

Clear and Streamlined Workflow: Prefabrication standardizes production and ensures each module is created with precise specifications. A clear sequence from factory casting to site installation eliminates unnecessary material handling, search time, and on-site coordination.

Labor and Time Savings: Mechanical clamping, automated demolding, and standardized mold design reduce the need for manual labor. Labor costs are cut by up to 40%, and fewer workers are required on-site, reducing congestion and labor management challenges.

High-Quality Finish: Controlled factory conditions allow for uniform concrete curing, smooth surfaces, and accurate dimensions. Modules achieve a fair-faced concrete finish, reducing post-construction finishing work and minimizing risks like water leakage or misalignment.

PPVC Casting Effect

Safety and Cleanliness: With the bulk of work completed in a factory, on-site activities generate less dust, noise, and debris. Lower exposure to high-risk construction tasks improves worker safety and creates a cleaner site environment.

Weather-Independent Production: Indoor prefabrication reduces delays caused by adverse weather, ensuring consistent production quality and predictable project timelines.

Sustainability and Green Building Alignment: PPVC Molds support low-carbon construction by minimizing material waste, reducing energy consumption on-site, and promoting modular reuse. The system aligns with modern sustainable building initiatives and environmental regulations.

Flexibility and Customization: Molds can be designed for a variety of module types and architectural layouts, including irregular or complex room designs, making PPVC Molds suitable for high-rise apartments, public housing, and commercial projects.

Improved Structural Integrity: Molds are produced under controlled conditions with precise reinforcement placement, enhancing overall structural strength and reducing the likelihood of construction errors.

GETO PPVC Precast Housing Molds

GETO Modular PPVC Construction Solutions

GETO specializes in PPVC molds and related formwork systems. With years of expertise in formwork and scaffolding manufacturing, GETO offers comprehensive solutions that enhance project efficiency and quality.

Why Choose GETO?

As a leading modular housing manufacturer in China, GETO delivers:

- Customized Design and Production: Tailored mold solutions to meet project-specific requirements.

- On-Site Support: Professional guidance ensures smooth installation and assembly.

- High-Quality Formwork Systems: Reliable molds and finished products guarantee structural integrity.

GETO PPVC Molds Applications

GETO provides a comprehensive range of mold solutions to support the prefabricated volumetric construction process. Each mold type is designed for efficiency, quality, and adaptability:

PPVC Precast Housing Molds: These molds form entire room modules, including floors, walls, ceilings, doors, and windows, in one casting. Ideal for high-rise apartments and residential projects, they significantly reduce construction time and labor.

Prefabricated Household Shelter (PHS) Molds: Specialized 3D molds designed for prefabricated household shelter units. PHS molds ensure durability, safety, and precision for emergency shelters and residential applications.

Prefabricated Bathroom Units (PBU) Molds: 3D molds for producing prefabricated bathroom units. PBUs enable quick installation of fully finished bathrooms, including walls, floors, and plumbing openings, minimizing on-site work and water leakage risk.

Prefabricated Bathroom Units (PBU) Molds

Molds for Pipe Gallery: Custom molds for precast pipe galleries streamline the installation of plumbing, HVAC, and electrical systems. They allow for precise alignment of conduits and service channels, improving efficiency and reducing on-site errors.

Molds for Box Culvert: Designed for infrastructure projects, these molds produce precast box culverts for water drainage, road crossings, and utility conduits. Standardized box culvert molds ensure consistent dimensions and rapid installation.

Molds for Lift Shaft (LS): LS molds produce precast lift shafts with high precision, providing structural stability and simplifying the installation of elevators in high-rise buildings. These molds can be customized to accommodate various elevator sizes and layouts.

GETO Project Cases: Transforming Prefabricated Construction Across Asia

Yishun North Gaia, Singapore: 11 towers built using 2,444 precast modules. GETO supplied 35 sets of automated molds and 17 sets of non-automated molds, facilitating high-precision casting.

Southeast Asia Apartment Project: Complex layouts with irregular corners were successfully executed using customized GETO Prefabricated Building Molds, ensuring efficient demolding and high-quality finishes.

PPVC Precast Housing Mold Applications

One Bernam, Singapore: 21 sets of automated molds cast 38 precast modules, demonstrating GETO’s capability to handle large-scale, complex PPVC projects.

HDB Public Housing Project: GETO’s PBU and PHS molds supported Singapore’s construction industrialization policy by enabling precise, efficient, and fast module production.

GETO combines expertise in formwork and scaffolding with innovative PPVC Molds solutions. By providing automated, semi-automated, and non-automated molds, GETO allows clients to select systems that best match project scale, budget, and complexity. The company also emphasizes sustainability, safety, and efficiency, delivering complete PPVC construction systems from factory to site.

Conclusion

PPVC Molds represents a highly efficient, safe, and environmentally friendly approach to modern construction. By prefabricating entire building modules off-site and using advanced formwork systems, projects can achieve faster delivery, higher quality, and reduced labor costs.

GETO’s PPVC precast housing molds, PBU, and PHS solutions provide clients with comprehensive, customized systems to realize these benefits, making it a trusted partner for prefabricated volumetric construction projects worldwide.

For inquiries or project consultations, reach out to geto_market@geto.com.cn and discover how GETO can bring your modular construction project to life!