Concrete formwork is a crucial component in construction. It shapes and supports concrete until it hardens, ensuring structural integrity and aesthetic quality.

Different materials can be used for formwork. These include wood, steel, aluminum, and plastic. Each material has its advantages and disadvantages.

Formwork techniques have evolved over time. From traditional timber formwork to engineered systems, the choice depends on the project's scale and complexity.

Safety is paramount when working with concrete formwork. Proper design and assembly are essential to withstand the pressure of fresh concrete.

This guide will delve into the various techniques of concrete formwork. It aims to provide a comprehensive understanding of how to select and use concrete forms effectively. Whether you're a construction professional, a DIY enthusiast, or simply curious, this guide is for you.

Understanding Concrete Formwork

Concrete formwork is an essential technique in construction. It involves creating a temporary mold into which concrete is poured and shaped.

Formwork plays a key role in construction. It provides a framework that supports the concrete as it cures and hardens.

The choice of formwork affects the final structure's quality and appearance. It's vital in ensuring that the concrete meets the desired tolerances and specifications.

Different projects require different formwork systems. The selection is influenced by factors such as design, budget, and construction timeline.

Advances in formwork technology have led to innovative solutions. These new techniques improve efficiency and reduce construction costs.

Materials Used in Concrete Formwork

Various materials are used for concrete formwork. The choice of material depends on the project's requirements and the intended reuse of the formwork.

Wood has been a traditional choice. It's easy to work with and adaptable to different shapes. However, it may not be the most durable option.

Steel formwork offers high strength and durability. It can be reused multiple times, making it a cost-effective choice for large projects.

Aluminum formwork is lightweight yet strong. It's ideal for situations where ease of handling is important.

Plastic formwork is another innovative material. It's resistant to weather and chemical reactions, providing longevity and reusability.

Each formwork material has its advantages and drawbacks. Here’s a quick list:

- Wood: Versatile but less durable.

- Steel: Strong and reusable but heavier.

- Aluminum: Lightweight and durable.

- Plastic: Weather-resistant and reusable.

The selection of formwork material can impact the construction timeline and budget. Proper material choice can lead to successful project outcomes.

Types of Concrete Forms and Their Applications

Concrete forms are essential in shaping and supporting newly poured concrete. They come in various types, each suited for different applications.

Traditional timber formwork is often used in small-scale projects. It's flexible, making it ideal for custom shapes and designs. However, it's usually not durable for repeated use.

Engineered formwork systems are gaining popularity in large construction projects. They are pre-designed modules that save both time and labor. These systems are known for their structural support and ease of assembly.

Reusable and prefabricated formwork can significantly cut project costs. These forms are designed for multiple uses, reducing waste and contributing to sustainable practices.

Concrete forms can also be categorized as shuttering forms, which are temporary, or permanent insulators, which provide additional benefits like thermal insulation.

Selecting the proper type of formwork ensures structural integrity and aesthetic quality. The choice often depends on the project size and specific requirements.

Some types to consider are:

- Traditional Timber: Customizable but less durable.

- Engineered Systems: Labor-efficient and robust.

- Reusable Prefab: Economical and eco-friendly.

Innovations in formwork technology continue to advance, offering more efficient and sustainable options for builders.

Traditional Timber Formwork

Traditional timber formwork is still used due to its versatility. It's perfect for projects needing unique shapes and designs.

The ease of cutting and shaping timber is its main advantage. However, it's not ideal for repeated use.

Projects of smaller scale benefit from timber's adaptability. Yet, it requires skilled craftsmanship for best results.

Engineered Formwork Systems

Engineered formwork systems streamline construction projects. They are prefabricated and provide strong structural support.

These systems reduce construction time. Their modular nature allows for quick assembly and disassembly on-site.

Such systems are optimal for large projects, ensuring precise and safe concrete placement.

Reusable and Prefabricated Formwork

Reusable formwork is cost-effective and eco-friendly. It can be used multiple times without significant wear.

Prefabricated options simplify construction logistics. They arrive ready to be installed, saving time and labor.

This formwork type aligns well with sustainable practices. It’s a smart choice for environmentally conscious projects.

Design and Safety Considerations

Proper design in concrete formwork is crucial for both safety and efficiency. A well-thought-out design ensures that the form can withstand the pressures and weight of wet concrete.

Considerations include material selection and load-bearing capacity. Using the correct formwork type helps maintain stability during the curing process.

Safety practices should always be prioritized. This includes proper installation and adherence to relevant standards.

Regular inspection of formwork is necessary to identify any potential hazards. It ensures the integrity of the setup.

Understanding the interplay between design and safety can lead to successful and incident-free construction projects.

Formwork Design and Pressure Calculations

Accurate pressure calculations are integral to formwork design. These calculations determine the stress exerted by fresh concrete.

Overestimating pressure can lead to overdesign, while underestimating risks formwork failure. Factors like concrete type and pour rate affect pressure levels.

Engineers use software tools for precise calculations. This minimizes risks and ensures that formwork supports the concrete safely.

Safety and Best Practices

Implementing safety measures is vital in formwork operations. Workers must be trained to use formwork systems correctly.

Best practices include using safety gear and following guidelines for formwork assembly and dismantling. Regular inspections are crucial to identify and rectify potential issues.

Employing these practices reduces accidents and fosters a safer work environment. Ensuring safety enhances efficiency and lowers project risks.

Innovative Techniques and Future Trends

The field of concrete formwork is continually evolving, introducing new methods and technologies. Innovations are reducing construction time and costs significantly.

Technological advancements like digital modeling improve precision in formwork design. They facilitate complex shapes and structures that were once challenging.

Robotic systems are beginning to automate formwork tasks, increasing efficiency. Their precision and speed reduce human errors and improve safety.

3D printing emerges as a promising trend. It allows for the creation of intricate and customizable formwork designs.

These innovations indicate a bright future for concrete formwork, making it smarter and more adaptable.

Climbing, Slip, and Jump Forming

Climbing formwork is ideal for high-rise structures. It moves upwards with the building, reducing labor needs.

Slip forming involves a continuous pour of concrete. The form moves slowly, creating smooth, vertical structures.

Jump forming is similar but used for distinct sections. It's fast and efficient, particularly for tall towers.

Sustainable Practices and Technological Advancements

Sustainability is gaining focus in construction. Reusable forms are reducing waste and resource depletion.

Bio-based materials are emerging in formwork. These eco-friendly options lessen environmental impact.

New technological tools aid in precision and reduced material use. They streamline processes, leading to less waste and higher efficiency.

Cost and Environmental Impact

The cost of concrete formwork plays a crucial role in construction budgets. Optimizing formwork design can lead to significant savings.

Choosing the right materials impacts both cost and performance. Reusable forms, though initially costly, save money over multiple projects.

Formwork's environmental impact is another concern. The production and disposal of materials affect ecological footprints.

Adopting sustainable practices in formwork can reduce carbon emissions. Using eco-friendly materials and methods alleviates environmental stress.

The balance between cost and sustainability is essential. Efficient planning can achieve economic savings while being environmentally conscious.

Types of reusable formwork systems

Reusable formwork systems come in various types, each suited to different construction needs. Steel formwork is extremely durable and ideal for high-rise and large-scale projects, while aluminum formwork offers a lighter alternative with high reusability, commonly used in residential construction. Plastic formwork is lightweight, waterproof, and easy to handle, making it suitable for small to medium projects.

Wood-plastic composite formwork combines flexibility and durability, offering a sustainable option. For complex or decorative concrete shapes, glass-reinforced plastic (GRP) formwork provides excellent surface finishes. Fabric formwork, made from high-strength textiles, allows for unique architectural designs, though with limited reuse. Lastly, modular formwork systems, often made of steel, aluminum, or plastic, are efficient and fast to assemble, ideal for repetitive or standardized construction.

Conclusion and Key Takeaways

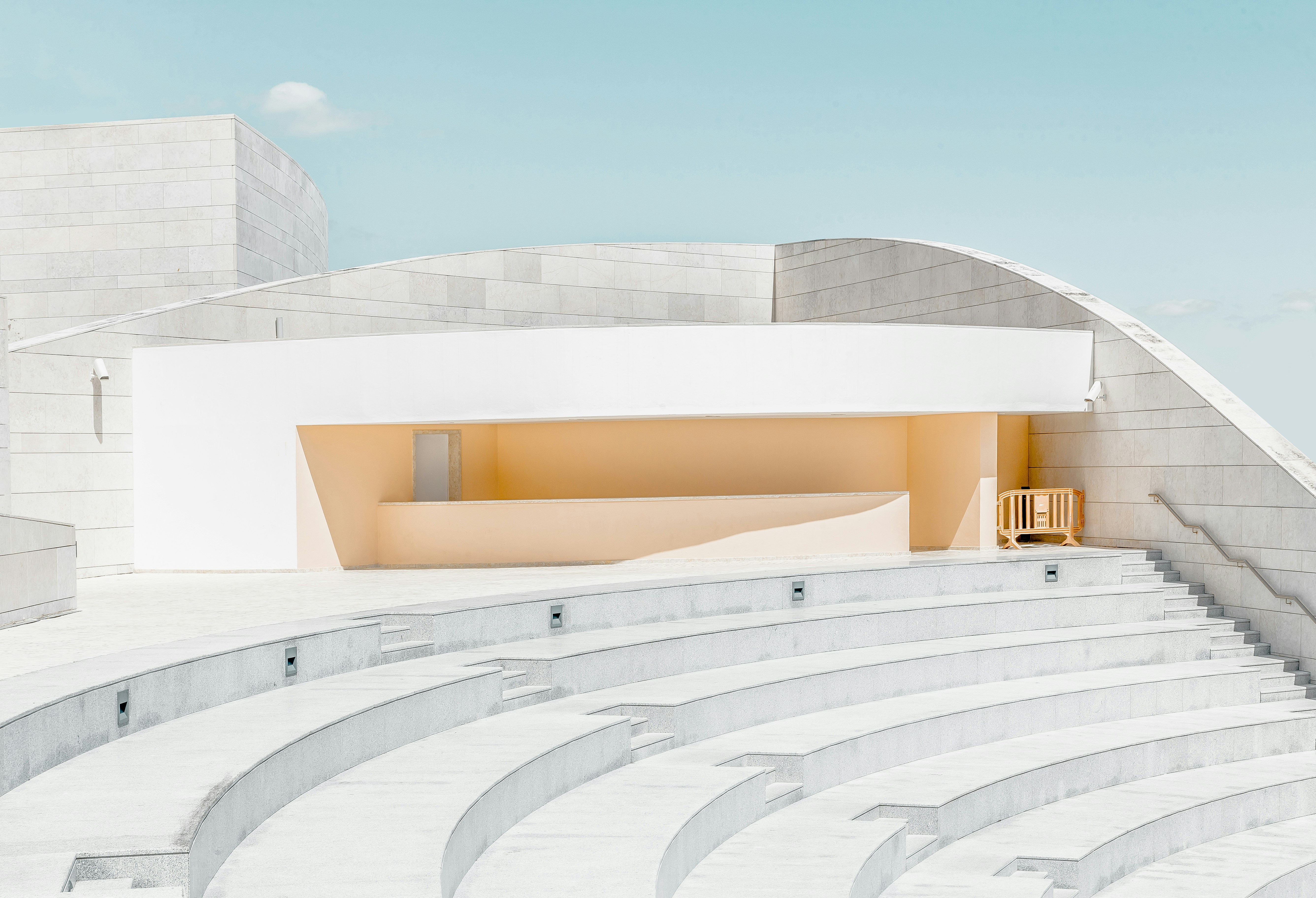

Concrete formwork is vital for shaping and supporting concrete structures. It ensures durability and aesthetic appeal.

Choosing suitable materials and techniques enhances efficiency. Understanding costs and environmental impacts is equally important.

Innovative practices and planning are essential for success. By mastering formwork, projects achieve structural and economic goals.

The Evolution of Concrete Formwork: From Timber Diagrams to Engineered Reusable Systems

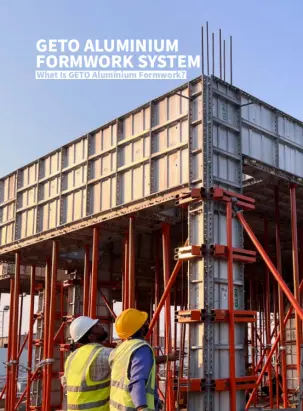

In modern construction, concrete formwork plays a crucial role in shaping and ensuring the quality of concrete structures. With advancements in technology, more engineers are turning to engineered formwork systems that offer greater stability while significantly improving construction efficiency and safety.

There are various types of reusable formwork systems available on the market, designed to be used repeatedly to meet different project requirements, making them both eco-friendly and cost-effective. For example, traditional timber formwork remains popular, and with clear timber formwork diagrams, designers can precisely understand the assembly methods and dimensional requirements to ensure flawless execution.

Meanwhile, concrete formwork design continues to evolve, focusing not only on load-bearing capacity but also on ease of assembly and adaptability to complex structures, allowing every architectural detail to be perfectly realized. These innovations make construction sites more efficient and guarantee higher project quality.